ED Decision 2021/015/R

1.0 Purpose

This AMC provides information, guidelines, recommendations, and acceptable means of compliance for use by applicants in the production of performance information for aeroplanes when taking off from runways that are slippery wet or contaminated by standing water, slush, snow, and ice.

2.0 Technical

Limitations of Data

The methodology specified in this AMC provides one acceptable means of compliance with the provisions of CS 25.1591. In general it does not require aeroplane testing on contaminated runway surfaces, although such testing if carried out at the discretion of the applicant may significantly improve the quality of the result or reduce the quantity of analytical work required.

Due to the nature of naturally occurring runway contaminants and difficulties associated with measuring aeroplane performance on such surfaces, any data that is either calculated or measured is subject to limitations with regard to validity. Consequently the extent of applicability should be clearly stated.

The properties specified in this AMC for various contaminants are derived from a review of the available test and research data and are considered to be acceptable for use by applicants. This is not an implied prohibition of data for other conditions or that other conditions do not exist.

EASA acknowledges that the observing of and reporting on the type and depth of runway surface contaminants (water, slush, dry snow, wet snow) is limited. This information may not be accurately and timely relayed to the flight crew. Furthermore, shallow depths of contaminants do not generally reduce wheel braking friction below that of a wet runway, except in unfavourable circumstances where lower than expected runway condition codes (RWYCCs) are reported (see AMC 25.1592). In line with International Civil Aviation Organization (ICAO) and Federal Aviation Administration (FAA) standards, EASA considers a depth of more than 3 mm for loose contaminant accountability in take-off performance assessments a reasonable lower threshold. If the depth of such loose contaminant is lower than 3 mm, or if there is a thin layer of frost, the runway is considered wet, for which this AMC 25.1591 does not apply.

It is intended that the use of aeroplane performance data for contaminated runway conditions produced in accordance with CS 25.1591 should include recommendations associated with the operational use of the data. Where possible, this operational guidance should be provided by the applicant or its production co-ordinated with the applicant to ensure that its use remains valid.

Operators are expected to make careful and conservative judgments in selecting the appropriate performance data to use for operations on contaminated runways. Particular attention should be paid to the presence of any contaminant in the critical high speed portion of the runway. For takeoff, it may be appropriate to use different contaminant types or depths for the takeoff and the accelerate-stop portions. For example, it may be appropriate to use a greater contaminant depth or a contaminant type that has a more detrimental effect on acceleration for the takeoff portion than for the accelerate-stop portion of the takeoff analysis.

In considering the maximum depth of runway contaminants it may be necessary to take account of the maximum depth for which the engine air intakes have been shown to be free of ingesting hazardous quantities of water in accordance with CS 25.1091(d)(2).

3.0 Standard

Assumptions

Due to the wide variation in possible conditions when operating on contaminated runways and the limitations inherent in representing the effects of these conditions analytically, it is not possible to produce performance data that will precisely correlate with each specific operation on a contaminated surface. Instead, the performance data should be determined for a standardised set of conditions that will generally and conservatively represent the variety of contaminated runway conditions occurring in service.

It should be assumed that:

— the contaminant is spread over the entire runway surface to an even depth (although rutting, for example, may have taken place).

— the contaminant is of a uniform specific gravity.

— where the contaminant has been sanded, graded (mechanically levelled) or otherwise treated before use, that it has been done in accordance with agreed national procedures.

4.0 Definitions

The following definitions are a subset of the runway surface condition descriptors for which a representative take‑off performance model may be derived using the methods contained in this AMC.

4.1 Frost

Ice crystals formed from airborne moisture on a surface whose

temperature is below freezing. Frost differs from ice in that frost crystals

grow independently and, therefore, have a more granular texture.

Note 1: ‘below freezing’ refers to air temperature equal to or

lower than the freezing point of water (0 C/32°F).

Note 2: under certain conditions, frost can render the runway

surface very slippery, which should then be appropriately reported as ‘reduced

braking action’.

4.1.a Standing water

Water of a depth greater than 3mm.

Note: a surface condition where there is a layer of water of 3 mm

or less is considered wet, for which this AMC 25.1591 is not applicable.

4.2 Slush

Snow that is so water-saturated that water will drain from it when a handful is picked up or will splatter if stepped on forcefully.

4.3 Wet snow

Snow that contains enough water to be able to make a well-compacted, solid snowball, without squeezing out water.

4.4 Dry snow

Snow from which a snowball cannot readily be made.

4.5 Compacted snow

Snow that has been compacted into a solid mass such that aeroplane tyres, at operating pressures and loadings, will run on the runway surface without significant further compaction or rutting of the runway surface.

4.6 Ice

Water that has frozen or compacted snow that has transitioned into ice, in cold and dry conditions.

Note: this definition excludes wet ice that has a film of water on top of it or contains melting ice, which provides minimal braking friction and uncertain lateral control.

4.7 Slippery wet runway

A wet runway where the surface friction characteristics on a significant portion of the runway have been determined to be degraded.

4.8 Specially prepared winter runway

A runway, with a dry frozen surface of compacted snow and/or ice which has been treated with sand or grit or has been mechanically or chemically treated to improve runway friction. The runway friction is monitored and reported on a regular basis in accordance with national procedures.

4.9 Specific gravity

The density of the contaminant divided by the density of the water.

5.0 Contaminant Properties to be Considered

5.1 Range of Contaminants

The following general range of conditions or properties may by used. The list given in Table 1 is not necessarily comprehensive and other contaminants may be considered, provided account is taken of their specific properties.

Data should assume the contaminant to be uniform in properties and uniformly spread over the complete runway.

Contaminants can be classified as being:-

(i) Drag producing, for example by contaminant displacement or impingement,

(ii) Braking friction reducing, or

(iii) A combination of (i) and (ii).

Data to be produced should use the classification and assumptions of Table 1 and then the appropriate sections of the AMC as indicated.

|

Contaminant |

Range of Depths to be Considered — mm |

Specific Gravity Assumed for Calculation |

Is Drag Increased? |

Is Braking Friction Reduced below Dry Runway

Value? |

Analysis Paragraphs Relevant |

|

Standing water, Flooded runway |

More than 3 up to 15 (see Note 1) |

1.0 |

Yes |

Yes |

7.1, 7.3, 7.4 |

|

Slush |

More than 3 up to 15 (see Note 1) |

0.85 |

Yes |

Yes |

7.1, 7.3, 7.4 |

|

Wet snow |

More than 3 up to 5 (see Note 1) |

|

No |

Yes |

7.3, 7.4 |

|

Wet snow |

More than 5 |

0.5 |

Yes |

Yes |

7.1, 7.3, 7.4 |

|

Dry snow |

More than 3 (see Note 1) |

|

No |

Yes |

7.3, 7.4 |

|

Dry Snow |

More

than 10 |

0.2 |

Yes |

Yes |

7.2, 7.3, 7.4 |

|

Compacted

snow at or below outside air temperature (OAT) of |

0 (see Note 4) |

|

No |

Yes |

7.3, 7.4 |

|

Compacted snow above

OAT of |

0 (see Note 4) |

|

No |

Yes |

7.3, 7.4 |

|

Dry snow over compacted snow |

More than 10 |

0.2 |

Yes |

Yes |

7.2, 7.3, 7.4 |

|

Wet snow over compacted snow (see Note 3) |

More than 5 up |

0.5 |

Yes |

Yes |

7.1, 7.3, 7.4 |

|

Ice (cold & dry) |

0 (see Note 4) |

|

No |

Yes |

7.3, 7.4 |

|

Slippery wet |

0 (see Note 4) |

|

No |

Yes |

7.3, 7.4 |

|

Specially prepared winter runway (see Note 5) |

0 (see Note 4) |

|

No |

Yes |

7.3.4, 7.4 |

Table 1

Note 1:

Runways with water depths or slush depths or snow depths of 3 mm or less are

considered wet, for which this AMC 25.1591 is not applicable.

Note 2:

Contaminant drag may be ignored.

Note 3: For

conservatism, the same landing gear displacement and impingement drag

methodology is used for wet snow as for slush.

Note 4:

Where depths are given as zero, it is assumed that the aeroplane is rolling on

the surface of the contaminant.

Note 5: No

default model is provided for specially prepared winter runways in this AMC.

Such runway surfaces are specific, and their treatment may be of variable

effectiveness. The competent authority of the State of operator should approve

the related procedures and methods.

5.2 Other Contaminants

Table 1

lists the contaminants commonly found.

It can be seen that the complete range of conditions or specific

gravities has not been covered.

Applicants may wish to consider other, less likely, contaminants in

which case such contaminants should be defined in a manner suitable for using

the resulting performance data in aeroplane operations.

6.0 Derivation

of Performance Information

6.1 General Conditions

Take-off

performance information for contaminated runways should be determined in

accordance with the assumptions given in paragraph 7.0.

Where

performance information for different contaminants are similar, the most

critical may be used to represent all conditions.

This AMC

does not set out to provide a complete technical analytical process but rather

to indicate the elements that should be addressed. Where doubt exists with

regard to the accuracy of the methodology or the penalties derived,

consideration should be given to validation by the use of actual aeroplane

tests or other direct experimental measurements.

6.2 Take-off on a Contaminated Runway

6.2.1 Except as modified by the effects of

contaminant as derived below, performance assumptions remain unchanged from

those used for a wet runway, in accordance with the agreed certification

standard. These include accelerate-stop distance definition, time delays,

take-off distance definition, engine failure accountability and stopping means

other than by wheel brakes (but see paragraph 7.4.3).

6.2.2 Where

airworthiness or operational standards permit operations on contaminated

runways without engine failure accountability, or using a VSTOP and

a VGO instead of a single V1, these performance

assumptions may be retained. In this case, a simple method to derive a single

V1 and associated data consistent with the performance

assumptions of paragraph 6.2.1 must also be provided in the AFM.

NOTE: VSTOP

is the highest decision speed from which the aeroplane can stop within the

accelerate-stop distance available. VGO is the lowest decision

speed from which a continued take-off is possible within the take-off distance

available.

7.0 Effects

of Contaminant

7.1 Contaminant Drag — Standing Water,

Slush, Wet Snow

General

advice and acceptable calculation methods are given for estimating the drag

force due to fluid contaminants on runways:

Total drag Drag due to Drag due to

airframe

due to fluid = fluid displacement + impingement

of fluid

contaminant by tyres spray from

tyres

The essence

of these simple calculation methods is the provision of appropriate values of

drag coefficients below, at, and above tyre aquaplaning speed, VP (see

paragraph 7.1.1):

—

Paragraphs

7.1.2.a and 7.1.2.b give tyre displacement drag coefficient values for speeds

below VP.

—

Paragraph

7.1.3.b.2 gives tyre equivalent displacement drag coefficient values to

represent the skin friction component of impingement drag for speeds below VP.

—

Paragraph

7.1.4 gives the variation with speed, at and above VP, of drag

coefficients representing both fluid displacement and impingement.

The

applicant may account for the contaminant drag for computing the deceleration

segment of the accelerate-stop distance. However, if the actual contaminant

depth is less than the reported value, then, using the reported value to

determine the contaminant drag will result in a higher drag level than the

actual one. This will lead to a conservative take-off distance and take-off

run, but also to a potentially optimistic accelerate-stop distance. It is

assumed that these effects will offset each other; however, the applicant may

consider:

—

either

using 100 % of the reported contaminant depth when determining the

acceleration portion, and 50 % when considering the deceleration portion; or

—

using

50 % of the reported contaminant depth when determining both the acceleration

portion and the stop portion of the accelerate-stop distance; this should

result in a conservative computation without being unduly penalising; the

applicant should ensure that using drag for 50 % of the reported contaminant

depth for computing the accelerate-stop distance is conservative for the

applicant’s aeroplane configuration.

7.1.1 Aquaplaning Speed

An aeroplane

will aquaplane at high speed on a surface that is contaminated by standing

water, slush or wet snow. For the purposes of estimating the effect of

aquaplaning on contaminant drag, the aquaplaning speed, VP, is

given by -

VP = 9

where VP

is the ground speed in knots and P is the tyre pressure in lb/in2.

To estimate

the effect of aquaplaning on wheel-to-ground friction, the aquaplaning speed

(VP) that is provided above should be factored by a coefficient of

0.85.

Predictions

(Reference 5) indicate that the effect of running a wheel over a low‑density

liquid contaminant containing air, e.g. slush, is to compress it such that it

essentially acts as high-density contaminant. This means that there is

essentially no increase in aquaplaning speed to be expected with such a lower

density contaminant. For this reason, the aquaplaning speed given here is not

a function of the density of the contaminant.

(See

References 1, 5 and 10)

7.1.2 Displacement

Drag

This is drag

due to the wheel(s) running through the contaminant and doing work by

displacing the contaminant sideways and forwards.

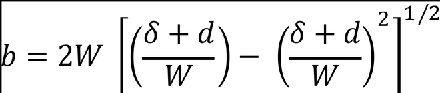

a. Single wheel.

The drag on

the tyre is given by -

D = CD½rV2S

Where r is the density of the

contamination, S is the frontal area of the tyre in the contaminant and V is

the groundspeed, in consistent units.

S = b x d

where d is the depth of contamination and b is the effective tyre width at the

contaminant surface and may be found from –

Where W is

the maximum width of the tyre and d is the tyre deflection, which may

be obtained from tyre manufacturers’ load-deflection curves.

The value of

CD may be taken as 0.75 for an isolated tyre below the aquaplaning speed, VP.

(See

Reference 3)

b. Multiple wheels

A typical

dual wheel undercarriage shows a drag 2.0 times the single wheel drag,

including interference. For a typical four-wheel bogie layout the drag is 4

times the single wheel drag (again including interference). For a six-wheel

bogie layout a reasonable conservative estimate suggests a figure of 4.2 times

the single wheel drag. The drag of spray striking the landing gear structure

above wheel height may also be important and should be included in the

analysis for paragraph 7.1.3.b.1 but for multiple wheel bogies the factors

above include centre spray impingement drag on gear structure below wheel

height.

(See

Reference 3)

7.1.3 Spray Impingement Drag

a. Determination of spray geometry

The sprays

produced by aeroplane tyres running in a liquid contaminant such as slush or

water are complex and depend on aeroplane speed, the shape and dimensions of

the loaded tyre and the contaminant depth. The spray envelope should be

defined, that is the height, width, shape and location of the sideways spray

plumes and, in the case of a dual wheel undercarriage, the centre spray

plumes. Additionally, a forward bow-wave spray will be present which may be

significant in drag terms should it impinge on the aeroplane.

In order to

assess the drag it is necessary to know the angles of the spray plumes so that

they can be compared with the geometry of the aeroplane. The angle at which the plumes rise is

generally between 10° and 20° but it varies considerably with speed and depth

of precipitation and to a small extent with tyre geometry. A method for estimating the plume angles in

the horizontal and vertical directions is given in References 1 and 7 and may

be used in the absence of experimental evidence. This information may be used to indicate

those parts of the airframe which will be struck by spray, in particular

whether the nose-wheel plume will strike the main landing gear or open

wheel-wells, the wing leading edges or the engine

nacelles, and whether the main-wheel plumes will strike the rear fuselage or

flaps.

b. Determination of the retarding forces

Following

definition of the spray envelopes, the areas of contact between the spray and

the airframe can be defined and hence the spray impingement drag determined.

This will be in two parts, direct interaction of the spray with the aeroplane

structure and skin friction.

For smaller

jet aeroplanes, typically those where the wing-to-ground height is less than 2

metres (6 feet), the methods contained in this document may not be

conservative. Drag estimates should be correlated with performance

measurements taken, for example, during water trough tests for engine ingestion.

b.1. Drag caused by direct impact of the spray

For

aeroplane designs where surface areas are exposed to direct spray impact, the

resulting drag forces should be taken into account. These forces exist where a

significant part of the spray flow is directed at part of the aeroplane

structure at a normal or non-oblique angle. The drag, or momentum loss of the

mass of fluid, so caused should be accounted for.

(See

Reference 6)

b.2. Drag caused by skin friction

Reference 2

explains that the relative velocity

between spray from the

landing gear and wetted aeroplane components causes drag due to skin friction

and provides a method for its calculation. Where more than one spray acts on

the same wing or fuselage surface the skin friction forces are not cumulative

and the single, higher calculated value should be used.

An

alternative, simple, conservative empirical estimate of skin friction drag,

which converts the skin friction drag into an equivalent displacement drag coefficient based on nose-wheel alone

drag measurements, is given by

CD

spray = 8 x L x 0.0025

where CD

spray is to be applied to the total nose-wheel displacement area (b x d x

number of wheels) and L is the wetted fuselage length in feet behind the point

at which the top of the spray plume reaches the height of the bottom of the

fuselage. This relation can also be used in the case of a main-wheel spray

striking the rear fuselage. In the case of any one main wheel unit only the

inner plume from the innermost leading wheel is involved so the relevant

displacement area is half that of one main wheel.

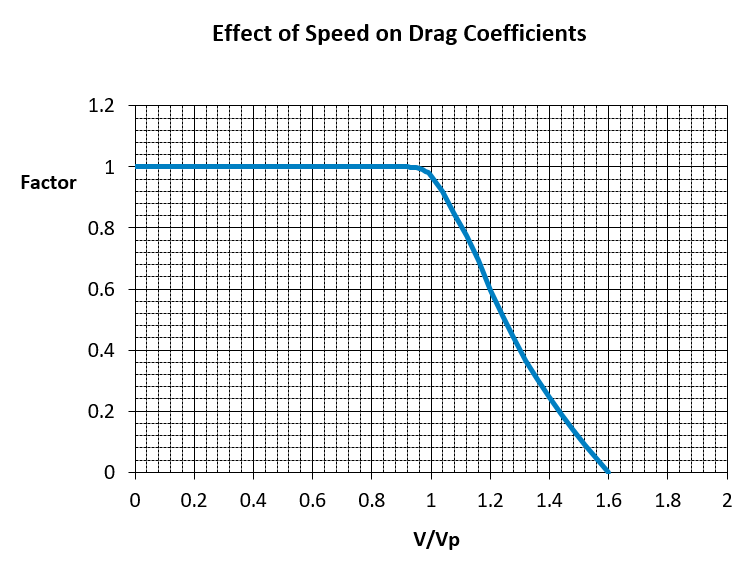

7.1.4 Effect of Speed on Displacement and

Impingement Drag Coefficients at and

above Aquaplaning Speed (VP)

The drag

above VP reduces to zero at lift off and one acceptable method is

to reduce CD as shown in the curve in Figure 1. This relationship

applies to both displacement and spray impingement drag coefficients.

Figure

1

7.2 Contaminant

Drag - Dry Snow

A basic method for calculating the drag of

aeroplane tyres rolling in dry snow is given herein. The method is based on

the theoretical model presented in References 8 and 9, using a specific

gravity of 0.2 as provided in Table 1. Only snow of specific gravity of 0.2 is

selected because it represents naturally occurring snow and results in the

highest drag variation with ground speed for the range of snow specific

gravities that are likely to be encountered. For other snow specific

gravities, the more detailed methods of Reference 8 should be used.

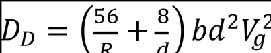

7.2.1 Single Tyre Drag

The total

displacement drag of a tyre rolling in dry snow is presented by the following

equation:

D = DC

+ DD

The term DC

represents the drag due to the compression of the snow by the tyre. The term

DD represents the drag due to the displacement of the snow

particles in a vertical direction.

The drag due

to snow compression for a single tyre for snow with a specific gravity of 0.2

is given by:

Tyre

pressure > 100 psi

DC =

74000 bd (Newtons)

Tyre

pressure 50 £ p £ 100

psi

DC =

56000 bd (Newtons)

In which:

d = snow

depth in metres

b = is

the tyre width at the surface in metres (see paragraph 7.1.2)

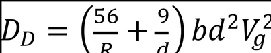

The drag due

to the displacement of the snow particles in a vertical direction for a single

tyre for snow with a specific gravity of 0.2 is given by:

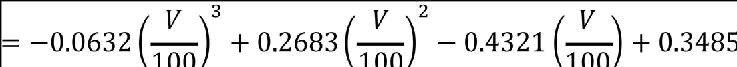

Tyre

pressure > 100 psi

Tyre

pressure 50 £ p £ 100

psi

In which:

d = snow

depth in metres

b = is

the tyre width at the surface in metres (see paragraph 7.1.2)

Vg = the

ground speed in m/s

R = tyre

radius in metres

For other

snow densities DC and DD can be calculated using the

method presented in Reference 8.

7.2.2 Multiple Wheels

The drag on

dual tyre landing gears (found on both nose and main gears) is simply the drag

of both single tyres added together. The interference effects between both

tyres, found on dual tyre configurations running through slush or water, are

not likely to be present when rolling over a snow covered surface. The drag

originates from the vertical compaction of the snow layer. Although there is

some deformation perpendicular to the tyre direction of motion, this

deformation occurs mainly at or below the bottom of the rut and therefore does

not affect the deformation in front of the adjacent tyre. Hence, interference

effects can be ignored.

In the case

of a bogie landing gear only the leading tyres have to be considered for the

drag calculation, as explained in Reference 8. After the initial compression

of the snow by the leading tyres, the snow in the rut becomes stronger and a

higher pressure must be applied to compress the snow further. Therefore, the

drag on the trailing tyres can be neglected and the drag on a bogie landing

gear is assumed to be equal to that of a dual tyre configuration. All other

multiple-tyre configurations can be treated in the same manner.

7.2.3 Spray Impingement Drag

Experiments

have shown that the snow spray coming from the tyres is limited with only

small amounts striking the airframe. The speed and the density of the snow

spray are much lower than, for instance, that of water spray. Therefore, the

drag due to snow impingement on the airframe can be neglected.

7.2.4 Total Landing Gear Drag

To obtain

the total drag on the tyres due to snow, DC and DD for

each single tyre (excluding the trailing tyres of a bogie gear) should be

calculated and summed.

7.3 Braking Friction (All Contaminants)

On most

contaminant surfaces the braking action of the aeroplane will be impaired. Performance

data showing these effects can be based on either the minimum conservative

‘default’ values, given in Table 2 or test evidence and assumed values (see

paragraph 7.3.2). In addition the applicant may optionally provide performance

data as a function of aeroplane braking coefficient or wheel braking

coefficient.

7.3.1 Default Values

To enable

aeroplane performance to be calculated conservatively in the absence of any

direct test evidence, default wheel-braking

coefficient values as

defined in Table 2 may be used. These values represent the maximum effective wheel-braking coefficient of a fully

modulating anti-skid controlled braked wheel/tyre. For quasi modulating

systems, the applicant should multiply the listed wheel-braking coefficient by

0.625, and for on-off systems, multiply the listed wheel-braking coefficient

by 0.375. For the classification of anti-skid systems, the applicant should

refer to AMC 25.109(c)(2). Aeroplanes without anti-skid

systems should be addressed separately on a case-by-case basis.

|

Contaminant |

Default Wheel-Braking Coefficient m |

|

Standing water and slush |

where V is ground speed in knots Note:

For V greater than 85 % of the aquaplaning speed (VP),

use the = 0.05 constant. At the discretion of the applicant, the wheel‑braking

coefficient as defined for runway condition codes (RWYCC) 2 in AMC 25.1592 may be applied. |

|

Wet snow above 3 mm

depth |

0.16 |

|

Dry snow above 3 mm depth |

0.16 |

|

Wet snow over compacted snow |

0.16 |

|

Dry snow over compacted snow |

0.16 |

|

Compacted snow below outside air temperature (OAT)

of -15 °C |

0.20 |

|

Compacted snow above OAT of |

0.16 |

|

Ice |

0.07 |

|

Slippery wet |

0.16 |

Note: Braking Force = load on braked wheel x

Default Friction Value m

Table

2

Note: For a

specially prepared winter runway surface no default friction value can be

given due to the diversity of conditions that will apply.

(See

reference 10)

7.3.2 Other Than Default Values

In

developing aeroplane braking performance using either test evidence or assumed

friction values other than the default values provided in Table 2, a number of

other brake related aspects should be considered. Brake efficiency should be assumed to be

appropriate to the brake and anti-skid system behaviour on the contaminant

under consideration or a conservative assumption can be used. It can be assumed that wheel brake torque

capability and brake energy characteristics are unaffected. Where the tyre

wear state significantly affects the braking performance on the contaminated

surface, it should be assumed that there is 20% of the permitted wear range

remaining.

Where

limited test evidence is available for a model predecessor or derivative this

may be used given appropriate conservative assumptions.

7.3.3 Use of Ground Friction Measurement Devices

There is

not, at present, a correlation

between aircraft stopping capability and ground friction measuring devices. Hence, it

is not practicable at present to determine aeroplane performance on the basis

of a friction index measured by ground friction devices. Notwithstanding this

lack of correlation, the applicant may optionally

choose to present take-off performance data as a function of an aeroplane

braking coefficient or wheel braking coefficient constant with ground speed

for runways contaminated with compacted snow or ice. The responsibility for

relating this data to a friction index measured by a ground friction device

will fall on the operator and the competent authority of the

State of operator.

7.3.4 Specially prepared winter runway surfaces

At the

discretion of the applicant, take-off performance data may be provided for

specially prepared winter runway surfaces. This may include icy surfaces that

have been treated with sand or gravel in such a way that a significant

improvement of friction may be demonstrated. The applicant should apply a

reasonable margin to the observed braking action in performance computations

for such surfaces, and assume wheel-braking coefficients no greater than 0.20

for fully modulating anti‑skid systems. For other anti-skid system types, this

coefficient must be factored as described in Section 7.3.1. The competent

authority of the State of aerodrome should approve appropriate procedures and

methods in compliance with point ADR.OPS.B.036 of Annex IV (Part-ADR.OPS) of

Regulation (EU) No 139/2014 (‘Aerodromes Regulation’).

7.4 Additional Considerations

7.4.1 Minimum V1

For the

purpose of take-off distance determination, it has been accepted that the

minimum V1 speed may be established using the VMCG value

established in accordance with CS 25.149(g). As implied in paragraph 8.1.3, this may not ensure that the

lateral deviation after engine failure will not exceed 30 ft on a contaminated

runway.

7.4.2 Reverse Thrust

Performance

information may include credit for reverse thrust where available and

controllable, as described in AMC 25.109.

8.0 Presentation of Supplementary Performance

Information

8.1 General

Performance

information for contaminated runways, derived in accordance with the

provisions of paragraphs 5.0 to 7.0, should be accompanied by appropriate

statements such as:

8.1.1 Operation on runways contaminated with water,

slush, snow, ice or other contaminants implies uncertainties with regard to

runway friction and contaminant drag and therefore to the achievable

performance and control of the aeroplane during take-off, since the actual

conditions may not completely match the assumptions on which the performance

information is based. Where possible, every effort should be made to ensure

that the runway surface is cleared of any significant contamination.

8.1.2 The performance information assumes any

runway contaminant to be of uniform depth and density.

8.1.3 The provision of performance information for

contaminated runways should not be taken as implying that ground handling

characteristics on these surfaces will be as good as can be achieved on dry or

wet runways, in particular following engine failure, in crosswinds or when

using reverse thrust.

8.1.4 The contaminated runway performance

information does not in any way replace or amend the Operating Limitations and

Performance Information listed in the AFM, unless otherwise stated.

8.2 Procedures

In addition to performance information appropriate to operating on a contaminated runway, the AFM should also include recommended procedures associated with this performance information. Differences in other procedures for operation of the aeroplane on a contaminated surface should also be presented, e.g., reference to crosswinds or the use of high engine powers or derates.

8.3 Take-off Data

This should

be presented either as separate data appropriate to a defined runway

contaminant or as incremental data based on the AFM normal dry or wet runway

information.

The landing

distance must be presented either directly or with the factors required by the

operating manuals, with clear explanation where appropriate.

Where data

is provided for a range of contaminant depths, for example greater than 3, 6,

9, 12, 15 mm, then the AFM should clearly indicate how to define data for

contaminant depths within the range of contaminant depths provided.

The AFM

should provide:

—

the

performance data for operations on contaminated runways; and

—

definitions

of runway surface conditions.

The AFM

should state that operations are prohibited on runways with contaminant depths

greater than those for which data is provided. Instructions for the use of

that data should be provided in the appropriate documentation.

Where the AFM presents data using VSTOP and VGO,

it must be stated in the AFM that use of this concept is acceptable only where

operation under this standard is permitted.

9 References

Reference

sources containing worked methods for the processes outlined in 7.1 to 7.3.3

are identified below:

1. ESDU Data Item 83042, December 1983,

with Amendment A, May 1998, ‘Estimation of Spray Patterns Generated from the

Side of Aircraft Tyres Running in Water or Slush’.

2. ESDU Data Item 98001, May 1998, ‘Estimation

of Airframe Skin-Friction Drag due to Impingement of Tyre Spray’.

3. ESDU Data Item 90035*, November 1990,

with Amendment A, October 1992, ‘Frictional and Retarding Forces on Aircraft

Tyres, Part V: Estimation of Fluid Drag Forces’.

4. ESDU Memorandum No.97*, July 1998, ‘The

Order of Magnitude of Drag due to Forward Spray from Aircraft Tyres’.

5. ESDU Memorandum No. 96, reissue May 2011, ‘Operations on Surfaces Covered

with Slush’.

6. ESDU Memorandum No. 95, reissue October 2013,

‘Impact Forces Resulting From Wheel Generated Spray: Re-Assessment Of Existing

Data’.

7. NASA Report TP-2718 ‘Measurement of Flow

Rate and Trajectory of Aircraft Tire-Generated Water Spray’.

8. Van Es, G.W.H., ‘Method for Predicting

the Rolling Resistance of Aircraft Tires in Dry Snow’. AIAA Journal of

Aircraft, Volume 36, No.5, September-October 1999.

9. Van Es, G.W.H., ‘Rolling Resistance of

Aircraft Tires in Dry Snow’, National Aerospace Laboratory NLR, Technical

Report TR-98165, Amsterdam, 1998.

10. ESDU Data Item 72008*, May 1972, ‘Frictional

and retarding forces on aircraft tyres’, Part III: planning.

11. FAA AC 25-31, ‘Takeoff

Performance Data for Operations on Contaminated Runways’, dated 22 December 2015.

12. ICAO Document 10064, ‘Aeroplane

Performance Manual’, First Edition 2020.

* This document has been withdrawn by ESDU and is no longer available.

[Amdt 25/2]

[Amdt 25/27]