AMC 25.933(a)(1) Unwanted in-flight thrust reversal of turbojet

thrust reversers

ED

Decision 2020/001/R

1. PURPOSE.

This

Acceptable Means of Compliance (AMC) describes various acceptable means, for

showing compliance with the requirements of CS 25.933(a)(1), "Reversing

systems", of CS-25. These means are intended to provide guidance to supplement

the engineering and operational judgement that must form the basis of any

compliance findings relative to in-flight thrust reversal of turbojet thrust

reversers.

2. RELATED

CERTIFICATION SPECIFICATIONS.

CS 25.111, CS 25.143, CS 25.251, CS 25.571, CS 25.901, CS 25.903, CS 25.1155,

CS 25.1305,

CS 25.1309, CS 25.1322 and CS 25.1529

3. APPLICABILITY.

The

requirements of CS 25.933 apply to turbojet thrust reverser systems. CS 25.933(a) specifically applies to reversers intended for ground operation

only, while CS 25.933(b) applies to reversers intended for both ground

and in-flight use.

This AMC

applies only to unwanted thrust reversal in flight phases when the landing

gear is not in contact with the ground; other phases (i.e., ground operation)

are addressed by CS 25.901(c) and CS 25.1309.

4. BACKGROUND.

4.a. General. Most thrust reversers are intended

for ground operation only. Consequently, thrust reverser systems are generally

sized and developed to provide high deceleration forces while avoiding foreign

object debris (FOD) ingestion, aeroplane surface efflux impingement, and

aeroplane handling difficulty during landing roll. Likewise, aircraft flight

systems are generally sized and developed to provide lateral and directional

controllability margins adequate for handling qualities, manoeuvrability

requirements, and engine-out VMC lateral drift conditions.

In early

turbojet aeroplane designs, the combination of control system design and

thrust reverser characteristics resulted in control margins that were capable

of recovering from unwanted in-flight thrust reversal even on ground-use-only

reversers; this was required by the previous versions of CS 25.933.

As the

predominant large aeroplane configuration has developed into the high bypass

ratio twin engine-powered model, control margins for the in-flight thrust

reversal case have decreased. Clearly,

whenever and wherever thrust reversal is intended, the focus must remain on

limiting any adverse effects of thrust reversal. However, when demonstrating compliance with CS

25.933(a) or CS 25.933(b), the Authority has accepted that applicants may

either provide assurance that the aeroplane is controllable after an in-flight

thrust reversal event or that the unwanted in-flight thrust reversal event

will not occur.

Different

historical forms of the rule have attempted to limit either the effect or the

likelihood of unwanted thrust reversal during flight. However, experience has demonstrated that

neither method is always both practical and effective. The current rule, and this related advisory

material, are intended to allow either of these assurance methods to be

applied in a manner which recognises the limitations of each, thereby maximising

both the design flexibility and safety provided by compliance with the rule.

4.b. Minimising Adverse Effects. The primary

purpose of reversing systems, especially those intended for ground operation

only, is to assist in decelerating the aeroplane during landing and during an

aborted take-off. As such, the reverser must be rapid-acting and must be

effective in producing sufficient reverse thrust. These requirements result in

design characteristics (actuator sizing, efflux characteristics, reverse

thrust levels, etc.) that, in the event of thrust during flight, could cause

significant adverse effects on aeroplane controllability and performance.

If the

effect of the thrust reversal occurring in flight produces an unacceptable

risk to continued safe flight and landing, then the reverser operation and

de-activation system must be designed to prevent unwanted thrust reversal. Alternatively, for certain aeroplane

configurations, it may be possible to limit the adverse impacts of unwanted

thrust reversal on aeroplane controllability and performance such that the

risk to continued safe flight and landing is acceptable (discussed later in

this AMC).

For

reversing systems intended for operation in flight, the reverser system must

be designed to adequately protect against unwanted in-flight thrust reversal.

CS 25.1309

and CS 25.901(c) and the associated AMC (AMC 25.1309

and AMC 25.901(c) provide guidance for developing and assessing

the safety of systems at the design stage. This methodology should be applied

to the total reverser system, which includes:

—

the

reverser;

—

the

engine (if it can contribute to thrust reversal);

—

the

reverser motive power source;

—

the

reverser control system;

—

the

reverser command system in the cockpit; and

—

the

wiring, cable, or linkage system between the cockpit and engine.

Approved

removal, deactivation, reinstallation, and repair procedures for any element

in the reverser or related systems should result in a safety level equivalent

to the certified baseline system configuration.

Qualitative

assessments should be done, taking into account potential human errors

(maintenance, aeroplane operation).

Data

required to determine the level of the hazard to the aeroplane in case of

in-flight thrust reversal and, conversely, data necessary to define changes to

the reverser or the aeroplane to eliminate the hazard, can be obtained from

service experience, test, and/or analysis.

These data also can be used to define the envelope for continued safe

flight.

There are

many opportunities during the design of an aeroplane to minimise both the

likelihood and severity of unwanted in-flight thrust reversal. These opportunities include design features

of both the aeroplane and the engine/reverser system. During the design process, consideration

should be given to the existing stability and control design features, while

preserving the intended function of the thrust reverser system.

Some design

considerations, which may help reduce the risk from in-flight thrust reversal,

include:

4.b.(1)

Engine location to:

(i) Reduce sensitivity to efflux impingement.

(ii) Reduce effective reverse thrust moment

arms

4.b.(2)

Engine/Reverser System design to:

(i) Optimise engine/reverser system integrity

and reliability.

(ii) Rapidly reduce engine airflow (i.e.

auto-idle) in the event of an unwanted thrust reversal. Generally, such a feature is considered a

beneficial safety item. In this case, the probability and effect of any

unwanted idle command or failure to provide adequate reverse thrust when

selected should be verified to be consistent with AMC 25.1309 and AMC 25.901(c).

(iii) Give consideration to the aeroplane pitch,

yaw, and roll characteristics.

(iv) Consider effective efflux diameter.

(v) Consider efflux area.

(vi) Direct reverser efflux away from critical

areas of the aeroplane.

(vii) Expedite detection of unwanted thrust

reversal, and provide for rapid compensating action within the reversing

system.

(viii) Optimise positive aerodynamic stowing

forces.

(ix) Inhibit in-flight thrust reversal of

ground-use-only reversers, even if commanded by the flight crew.

(x) Consider incorporation of a restow

capability for unwanted thrust reversal.

4.b.(3)

Airframe/System design to:

(i) Maximise aerodynamic control capability.

(ii) Expedite detection of thrust reversal, and

provide for rapid compensating action through other airframe systems.

(iii) Consider crew procedures and responses.

The use of

formal «lessons learned»-based reviews early and often during design

development may help avoid repeating previous errors and take advantage of

previous successes.

5. DEFINITIONS.

The

following definitions apply for the purpose of this AMC:

a. Catastrophic: see AMC 25.1309

b. Continued Safe Flight and Landing: The

capability for continued controlled flight and safe landing at an airport,

possibly using emergency procedures, but without requiring exceptional pilot

skill or strength. Some aeroplane damage may be associated with a failure

condition, during flight or upon landing.

c. Controllable Flight Envelope and

Procedure: An area of the Normal Flight

Envelope where, given an appropriate procedure, the aeroplane is capable of

continued safe flight and landing following an in-flight thrust reversal.

d. Deactivated Reverser: Any thrust reverser that has been

deliberately inhibited such that it is precluded from performing a normal

deploy/stow cycle, even if commanded to do so.

e. Exceptional Piloting Skill and/or

Strength: Refer to CS 25.143(c)(c) («Controllability and

Manoeuvrability—General»).

f. Extremely Improbable: see AMC 25.1309

g. Extremely Remote: see AMC 25.1309

h. Failure: see AMC 25.1309

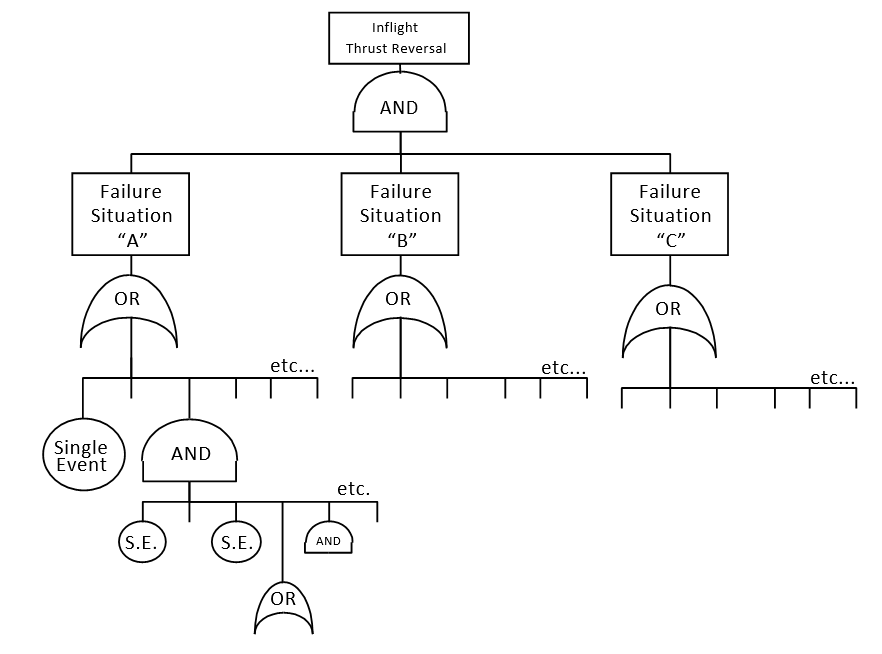

i. Failure Situation: All failures that result in the malfunction

of one independent command and/or restraint feature that directly contributes

to the top level Fault Tree Analysis event (i.e., unwanted in-flight thrust

reversal). For the purpose of illustration, Figure 1, below, provides a fault

tree example for a scenario of three «failure situations» leading to unwanted

in-flight thrust reversal.

Figure 1: TOP EVENT

Reverser System with three independent command/restraint features shown

for reference only.

j. Hazardous: see AMC 25.1309

k. In-flight: that part of aeroplane

operation beginning when the wheels are no longer in contact with the ground

during the take-off and ending when the wheels again contact the ground during

landing.

l. Light Crosswind: For purposes of this

AMC, a light crosswind is a 19 km/h (10 Kt). wind at right angles to the

direction of take-off or landing which is assumed to occur on every flight.

m. Light Turbulence: Turbulence that

momentarily causes slight, erratic changes in altitude and/or attitude (pitch,

roll, and/or yaw), which is assumed to occur on every flight.

n. Major: see AMC 25.1309

o. Maximum exposure time: The longest anticipated period between the

occurrence and elimination of the failure.

p. Normal Flight Envelope: An established boundary of parameters

(velocity, altitude, angle of attack, attitude) associated with the practical

and routine operation of a specific aeroplane that is likely to be encountered

on a typical flight and in combination with prescribed conditions of light

turbulence and light crosswind.

q. Pre-existing failure: Failure that can

be present for more than one flight.

r. Thrust Reversal: A movement of all or

part of the thrust reverser from the forward thrust position to a position

that spoils or redirects the engine airflow.

s. Thrust Reverser System: Those components

that spoil or redirect the engine thrust to decelerate the aeroplane. The

components include:

—

the

engine-mounted hardware,

—

the

reverser control system,

—

indication

and actuation systems, and

—

any

other aeroplane systems that have an effect on the thrust reverser operation.

t. Turbojet thrust reversing system: Any

device that redirects the airflow momentum from a turbojet engine so as to

create reverse thrust. Systems may

include:

—

cascade-type

reversers,

—

target

or clamshell-type reversers,

—

pivoted-door

petal-type reversers,

—

deflectors

articulated off either the engine cowling or aeroplane structure,

—

targetable

thrust nozzles, or

—

a

propulsive fan stage with reversing pitch.

u. Turbojet (or turbofan): A gas turbine

engine in which propulsive thrust is developed by the reaction of gases being

directed through a nozzle.

6. DEMONSTRATING

COMPLIANCE WITH CS 25.933(a).

The

following Sections 7 through 10 of this AMC provide guidance on specific

aspects of compliance with CS 25.933(a), according to four different means or

methods:

—

Controllability

(Section 7),

—

Reliability

(Section 8),

—

Mixed

controllability / reliability (Section 9),

—

Deactivated

reverser (Section 10).

7. «CONTROLLABILITY

OPTION»: PROVIDE CONTINUED SAFE FLIGHT AND LANDING FOLLOWING ANY IN-FLIGHT

THRUST REVERSAL.

The

following paragraphs provide guidance regarding an acceptable means of

demonstrating compliance with CS 25.933(a)(1).

7.a. General. For compliance to be established

with CS 25.933(a) by demonstrating that the aeroplane is capable of continued

safe flight and landing following any in-flight thrust reversal (the

«controllability option» provided for under CS 25.933(a)(1)), the aspects of

structural integrity, performance, and handling qualities must be taken into

account. The level of accountability

should be appropriate to the probability of in-flight thrust reversal, in

accordance with the following sections.

To identify

the corresponding failure conditions and determine the probability of their

occurrence, a safety analysis should be carried out, using the methodology

described in CS 25.1309. The reliability of design features, such as auto-idle

and automatic control configurations critical to meeting the following

controllability criteria, also should be considered in the safety analysis.

Appropriate

alerts and/or other indications should be provided to the crew, as required by

CS 25.1309(c) (Ref. AMC 25.1309).

The

inhibition of alerts relating to the thrust reverser system during critical

phases of flight should be evaluated in relation to the total effect on flight

safety (Ref. AMC 25.1309).

Thrust

reversal of a cyclic or erratic nature (e.g., repeated deploy/stow movement of

the thrust reverser) should be considered in the safety analysis and in the

design of the alerting/indication systems.

Input from

the flight crew and human factors specialists should be considered in the

design of the alerting and/or indication provisions.

The

controllability compliance analysis should include the relevant thrust

reversal scenario that could be induced by a rotorburst event.

When

demonstrating compliance using this «controllability option» approach, if the

aeroplane might experience an in-flight thrust reversal outside the

«controllable flight envelope» anytime during the entire operational life of

all aeroplanes of this type, then further compliance considerations as

described in Section 9 («MIXED CONTROLLABILITY / RELIABILITY OPTION») of this

AMC, below, should be taken into account.

7.b. Structural Integrity. For the

«controllability option,» the aeroplane must be capable of successfully

completing a flight during which an unwanted in-flight thrust reversal occurs.

An assessment of the integrity of the aeroplane structure is necessary,

including an assessment of the structure of the deployed thrust reverser and

its attachments to the aeroplane.

In

conducting this assessment, the normal structural loads, as well as those

induced by failures and forced vibration (including buffeting), both at the

time of the event and for continuation of the flight, must be shown to be

within the structural capability of the aeroplane.

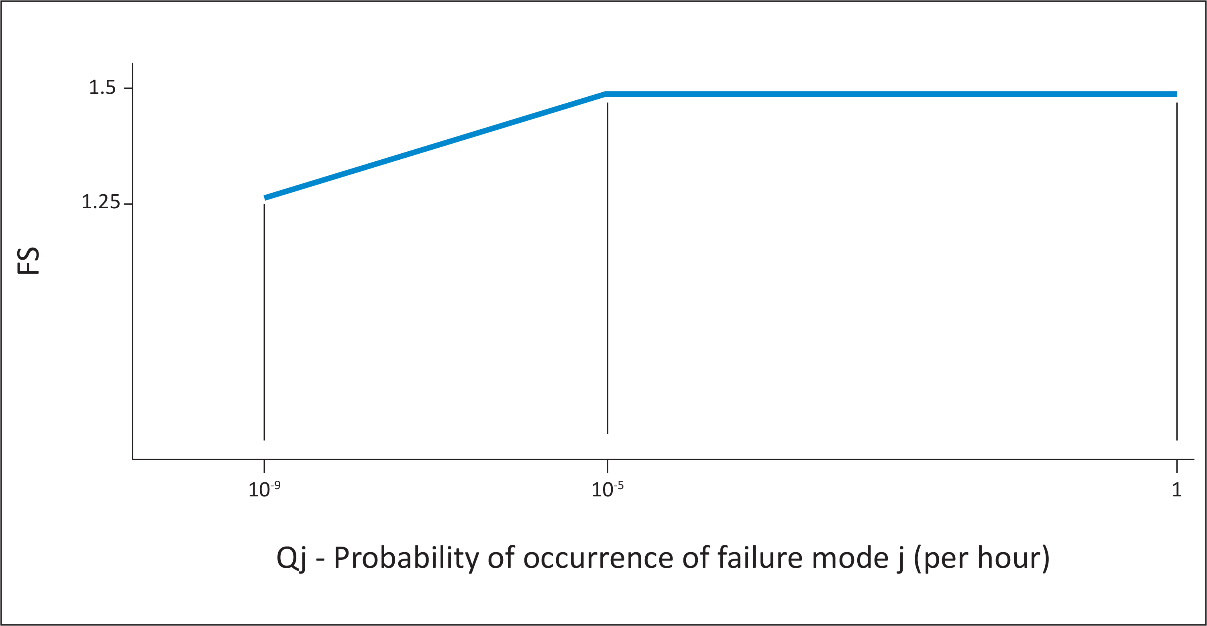

At the time

of occurrence, starting from 1-g level flight conditions, at speeds up to VC,

a realistic scenario, including pilot corrective actions, should be

established to determine the loads occurring at the time of the event and during

the recovery manoeuvre. The aeroplane should be able to withstand these loads

multiplied by an appropriate factor of safety that is related to the

probability of unwanted in-flight thrust reversal. The factor of safety is defined in Figure 2,

below. Conditions with high lift devices deployed also should be considered at

speeds up to the appropriate flap limitation speed.

Figure

2: Factor of safety at the time of occurrence

For

continuation of the flight following in-flight thrust reversal, considering

any appropriate reconfiguration and flight limitations, the following apply:

7.b.(1) Static

strength should be determined for loads derived from the following conditions

at speeds up to VC, or the speed limitation prescribed for the remainder of the flight:

(i) 70% of the limit flight manoeuvre loads;

and separately

(ii) the discrete gust conditions specified in CS 25.341(a)

(but using 40% of the gust velocities specified for VC).

7.b.(2)

For the aeroplane with high lift devices deployed, static strength should be

determined for loads derived from the following conditions at speeds up the

appropriate flap design speed, or any lower flap speed limitation prescribed

for the remainder of the flight:

(i) A balanced manoeuvre at a positive limit

load factor of 1.4; and separately

(ii) the discrete gust conditions specified in CS 25.345(a)(2) (but using 40% of the gust velocities specified).

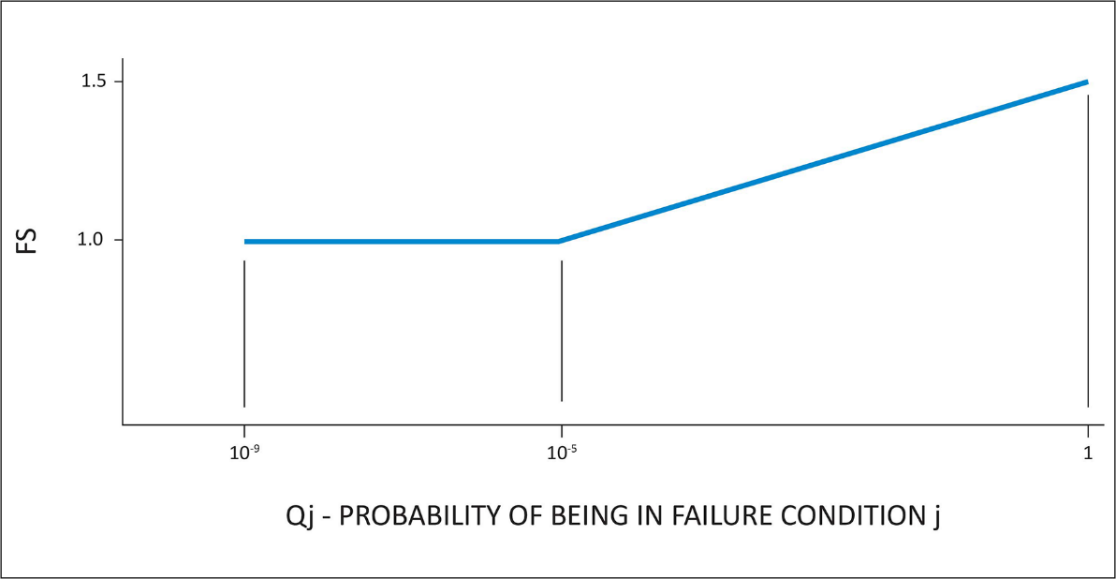

7.b.(3)

For static strength substantiation, each part of the structure must be able to

withstand the loads specified in sub-paragraph 7.b.(1) and 7.b.(2) of this

paragraph, multiplied by a factor of safety depending on the probability of

being in this failure state. The factor of safety is defined in Figure 3,

below.

Figure

3: Factor of safety for continuation of flight

Qj = is

the probability of being in the configuration with the unwanted in-flight

thrust reversal

Qj = (Tj)(Pj)

where:

Tj = average

time spent with unwanted in-flight thrust reversal (in hours)

Pj = probability

of occurrence of unwanted in-flight thrust reversal (per hour)

If the

thrust reverser system is capable of being restowed following a thrust

reversal, only those loads associated with the interval of thrust reversal need

to be considered. Historically, thrust

reversers have often been damaged as a result of unwanted thrust reversal

during flight. Consequently, any claim that the thrust reverser is capable of

being restowed must be adequately substantiated, taking into account this

adverse service history.

7.c. Performance

7.c.(1) General

Considerations: Most failure conditions that have an effect on performance are

adequately accounted for by the requirements addressing a «regular» engine

failure (i.e., involving only loss of thrust and not experiencing any reverser

anomaly). This is unlikely to be the case for failures involving an unwanted

in-flight thrust reversal, which can be expected to have a more adverse impact

on thrust and drag than a regular engine failure. Such unwanted in-flight

thrust reversals, therefore, should be accounted for specifically, to a level

commensurate with their probability of occurrence.

The

performance accountability that should be provided is defined in Sections

7.c.(2) and 7.c.(3) as a function of the probability of the unwanted in-flight

thrust reversal. Obviously, for unwanted in-flight thrust reversals less

probable than 1x10- 9 /fh, certification may be based on

reliability alone, as described in Section 8 («RELIABILITY OPTION») of this

AMC. Furthermore, for any failure conditions where unwanted in-flight thrust

reversal would impact safety, the aeroplane must meet the safety/reliability

criteria delineated in CS 25.1309.

7.c.(2)

Probability of unwanted in-flight thrust reversal greater than 1x10-7/fh:

Full performance accountability must be provided for the more critical of a

regular engine failure and an unwanted in-flight thrust reversal.

To determine

if the unwanted in-flight thrust reversal is more critical than a regular

engine failure, the normal application of the performance requirements

described in CS-25, Subpart B, as well as the applicable operating

requirements, should be compared to the application of the following criteria,

which replace the accountability for a critical engine failure with that of a

critical unwanted in-flight thrust reversal:

—

CS 25.111, «Take-off path»: The takeoff path

should be determined with the critical unwanted thrust reversal occurring at VLOF

instead of the critical engine failure at VEF. No change to the

state of the engine with the thrust reversal that requires action by the pilot

may be made until the aircraft is 122 m (400 ft) above the takeoff surface.

—

CS 25.121, «Climb: one-engine-inoperative»: Compliance

with the one-engine-inoperative climb gradients should be shown with the

critical unwanted in-flight thrust reversal rather than the critical engine

inoperative.

—

CS 25.123, «En-route flight paths»: The

en-route flight paths should be determined following occurrence of the

critical unwanted in-flight thrust reversal(s) instead of the critical engine

failure(s), and allowing for the execution of appropriate crew procedures. For

compliance with the applicable operating rules, an unwanted in-flight thrust

reversal(s) at the most critical point en-route should be substituted for the

engine failure at the most critical point en-route.

Performance

data determined in accordance with these provisions, where critical, should be

furnished in the Aeroplane Flight Manual as operating limitations.

Operational

data and advisory data related to fuel consumption and range should be

provided for the critical unwanted in-flight thrust reversal to assist the

crew in decision making. These data may

be supplied as simple factors or additives to apply to normal

all-engines-operating fuel consumption and range data. For approvals to conduct extended range

operations with two-engine aeroplanes (ETOPS), the critical unwanted in-flight

thrust reversal should be considered in the critical fuel scenario (paragraph

10d(4)(iii) of Information Leaflet no. 20: ETOPS).

In addition

to requiring full performance accountability as it relates to the specific

aeroplane performance requirements of Subpart B, all other aspects of the

aeroplane’s performance following a non-restowable in-flight thrust reversal

(e.g. capability to climb and maintain 305m (1000 feet) AGL) must be found

adequate to comply with the intent of CS 25.933(a)(1)(ii).

7.c.(3)

Probability of unwanted in-flight thrust reversal equal to or less than 1x10-7/fh,

but greater than 1x10-9/fh: With the exception of the takeoff phase

of flight, which needs not account for unwanted in-flight thrust reversal, the

same criteria should be applied as in Section 7.c.(2), above, for the purposes

of providing advisory data and procedures to the flight crew. Such performance

data, however, need not be applied as operating limitations. The takeoff data

addressed by Section 7.c.(2), above (takeoff speeds, if limited by VMC,

takeoff path, and takeoff climb gradients), does not need to be provided, as

it would be of only limited usefulness if not applied as a dispatch

limitation.

However, the

takeoff data should be determined and applied as operating limitations if the

unwanted in-flight thrust reversal during the take-off phase is the result of

a single failure.

As part of

this assessment, the effect of an unwanted in-flight thrust reversal on

approach climb performance, and the ability to execute a go-around manoeuvre

should be determined and used to specify crew procedures for an approach and

landing following a thrust reversal.

For example, the procedures may specify the use of a flap setting less

than that specified for landing, or an airspeed greater than the stabilised

final approach airspeed, until the flight crew is satisfied that a landing is

assured and a go-around capability need no longer be maintained. Allowance may

be assumed for execution of appropriate crew procedures subsequent to the

unwanted thrust reversal having occurred. Where a number of thrust reversal

states may occur, these procedures for approach and landing may, at the option

of the applicant, be determined either for the critical thrust reversal state

or for each thrust reversal state that is clearly distinguishable by the

flight crew.

Operational

data and advice related to fuel consumption and range should be provided for

the critical unwanted in-flight thrust reversal to assist the crew in

decision-making. These data may be supplied as simple factors or additives to

apply to normal all-engines-operating fuel consumption and range data.

The

aeroplane performance capabilities following a non-restowable in-flight thrust

reversal must be such that the probability of preventing continued safe flight

(e.g. capability to climb and maintain 305m (1000 feet) AGL) and landing at an

airport (i.e. either destination or diversion) is extremely improbable.

7.d. Handling Qualities

7.d.(1)

Probability of unwanted in-flight thrust reversal greater than 1x10-7/fh:

The more critical of an engine failure (or flight with engine(s) inoperative),

and an unwanted in-flight thrust reversal, should be used to show compliance

with the controllability and trim requirements of CS-25, Subpart B. In

addition, the criteria defined in Section 7.d.(2), below, also should be

applied. To determine if the unwanted in-flight thrust reversal is more

critical than an engine failure, the normal application of the CS-25, Subpart

B, controllability and trim requirements should be compared to the application

of the following criteria, which replace the accountability for a critical

engine failure with that of a critical unwanted in-flight thrust reversal:

—

CS 25.143, «Controllability and

Manoeuvrability - General»: the effect of a sudden unwanted in-flight thrust

reversal of the critical engine, rather than the sudden failure of the

critical engine, should be evaluated in accordance with CS 25.143(b)(1) and

the associated guidance material.

Control

forces associated with the failure should comply with CS 25.143(c).

—

CS 25.147, «Directional and lateral control»:

the requirements of CS 25.147(a), (b), (c), and

(d) should

be complied with following critical unwanted in-flight thrust reversal(s)

rather than with one or more engines inoperative.

—

CS 25.149, «Minimum control speed»: the

values of VMC and VMCL should be determined with a

sudden unwanted in-flight thrust reversal of the critical engine rather than a

sudden failure of the critical engine.

—

CS 25.161, «Trim» the trim requirements of CS 25.161(d) and (e)should be complied with following critical unwanted in-flight thrust

reversal(s), rather than with one or more engines inoperative.

Compliance

with these requirements should be demonstrated by flight test. Simulation or

analysis will not normally be an acceptable means of compliance for such

probable failures.

7.d.(2)

Probability of unwanted thrust reversal equal to or less than 1x10-7/fh,

but greater than 1x10-9/fh: failure conditions with a probability

equal to or less than 1x10-7/fh are not normally evaluated against

the specific controllability and trim requirements of CS-25, Subpart B.

Instead, the effects of unwanted in-flight thrust reversal should be evaluated

on the basis of maintaining the capability for continued safe flight and

landing, taking into account pilot recognition and reaction time. One exception

is that the minimum control speed requirement of CS 25.149 should be evaluated to the extent necessary to support the

performance criteria specified in Section 7.c.(3), above, related to approach,

landing, and go-around.

Recognition

of the failure may be through the behaviour of the aircraft or an appropriate

failure alerting system, and the recognition time should not be less than one

second. Following recognition,

additional pilot reaction times should be taken into account, prior to any

corrective pilot actions, as follows:

—

Landing:

no additional delay

—

Approach:

1 second

—

Climb,

cruise, and descent: 3 seconds; except when in auto-pilot engaged manoeuvring

flight, or in manual flight, when 1 second should apply.

Both

auto-pilot engaged and manual flight should be considered.

The unwanted

in-flight thrust reversal should not result in any of the following:

—

exceedance

of an airspeed halfway between VMO and VDF, or Mach

Number halfway between MMO and MDF

—

a

stall

—

a

normal acceleration less than a value of 0g

—

bank

angles of more than 60° en-route, or more than 30° below a height of 305m

(1000 ft)

—

degradation

of flying qualities assessed as greater than Major for unwanted in-flight

thrust reversal more probable than 1x10-7/fh; or assessed as

greater than Hazardous for failures with a probability equal to or less than

1x10-7/fh, but greater 1x10-9/fh

—

the

roll control forces specified in CS 25.143(c), except that the long term roll

control force should not exceed 10 lb

—

structural

loads in excess of those specified in Section 7.b., above.

Demonstrations

of compliance may be by flight test, by simulation, or by analysis suitably

validated by flight test or other data.

7.d.(3)

Probability of in-flight thrust reversal less than 1x10-9/fh:

Certification can be based on reliability alone as described in Section 8,

below.

8. ‘RELIABILITY

OPTION’: PROVIDE CONTINUED SAFE FLIGHT AND LANDING BY PREVENTING ANY IN-FLIGHT

THRUST REVERSAL

The

following paragraphs provide guidance regarding an acceptable means of

demonstrating compliance with CS 25.933(a)(1)(ii).

8.a. General. For compliance to be established

with CS 25.933(a) by demonstrating that unwanted in-flight thrust reversal is

not anticipated to occur (the «reliability option» provided for under CS

25.933(a)(1)(ii)), the aspects of system reliability, maintainability, and

fault tolerance; structural integrity; and protection against zonal threats

such as uncontained engine rotor failure or fire must be taken into account.

8.b. System Safety Assessment (SSA): Any

demonstration of compliance should include an assessment of the thrust

reverser control, indication and actuation system(s), including all

interfacing power-plant and aeroplane systems (such as electrical supply,

hydraulic supply, flight/ground status signals, thrust lever position signals,

etc.) and maintenance.

The

reliability assessment should include:

—

the

possible modes of normal operation and of failure;

—

the

resulting effect on the aeroplane considering the phase of flight and

operating conditions;

—

the

crew awareness of the failure conditions and the corrective action required;

—

failure

detection capabilities and maintenance procedures, etc.; and

—

the

likelihood of the failure condition.

Consideration

should be given to failure conditions being accompanied or caused by external

events or errors.

The SSA

should be used to identify critical failure paths for the purpose of

conducting in-depth validation of their supporting failure mode, failure

rates, exposure time, reliance on redundant subsystems, and assumptions, if

any. In addition, the SSA can be used

to determine acceptable time intervals for any required maintenance intervals

(ref. AMC 25.1309 and AMC 25.19).

The primary

intent of this approach to compliance is to improve safety by promoting more

reliable designs and better maintenance, including minimising pre-existing

faults. Latent failures involved in unwanted in-flight thrust reversal should

be avoided whenever practical. The design configurations in paragraphs 8.b.(2)

and 8.b.(3) have traditionally been considered to be practical and considered

to be acceptable to EASA.

8.b.(1) The thrust reverser system should be

designed so that any in-flight thrust reversal that is not shown to be

controllable in accordance with Section 7,above, is extremely improbable

(i.e., average probability per hour of flight of the order of 1x10-9/fh.

or less) and does not result from a single failure or malfunction. And

8.b.(2) For configurations in which combinations of

two-failure situations (ref. Section 5, above) result in in-flight thrust

reversal, the following apply:

Neither

failure may be pre-existing (i.e., neither failure situation can be undetected

or exist for more than one flight); the means of failure detection must be

appropriate in consideration of the monitoring device reliability, inspection

intervals, and procedures.

The

occurrence of either failure should result in appropriate cockpit indication

or be self-evident to the crew to enable the crew to take necessary actions

such as discontinuing a take-off, going to a controllable flight envelope

en-route, diverting to a suitable airport, or reconfiguring the system in

order to recover single failure tolerance, etc. And

8.b.(3) For configurations in which combinations of

three or more failure situations result in in-flight thrust reversal, the

following applies:

In order to

limit the exposure to pre-existing failure situations, the maximum time each

pre-existing failure situation is expected to be present should be related to

the frequency with which the failure situation is anticipated to occur, such

that their product is 1×10-3 or less.

The time

each failure situation is expected to be present should take into account the

expected delays in detection, isolation, and repair of the causal failures.

8.c. Structural Aspects: For the «reliability

option,» those structural load paths that affect thrust reversal should be

shown to comply with the static strength, fatigue, damage tolerance, and deformation

requirements of CS-25. This will ensure that unwanted in-flight thrust

reversal is not anticipated to occur due to failure of a structural load path,

or due to loss of retention under ultimate load throughout the operational

life of the aeroplane.

8.d. Uncontained Rotor Failure: In case of rotor

failure, compliance with CS 25.903(d)(1) should be shown, using advisory

materials (AC, user manual, etc.) supplemented by the methods described below.

The effects of associated loads and vibration on the reverser system should be

considered in all of the following methods of minimising hazards:

8.d.(1)

Show that engine spool-down characteristics or potential reverser damage are

such that compliance with Section 7, above, can be shown.

8.d.(2)

Show that forces that keep the thrust reverser in stable stowed position

during and after the rotor burst event are adequate.

8.d.(3)

Locate the thrust reverser outside the rotor burst zone.

8.d.(4)

Protection of thrust reverser restraint devices: The following guidance

material describes methods of minimising the hazard to thrust reverser stow

position restraint devices located within rotorburst zones. The following

guidance material has been developed on the basis of all of the data available

to date and engineering judgement.

8.d.(4)(i)

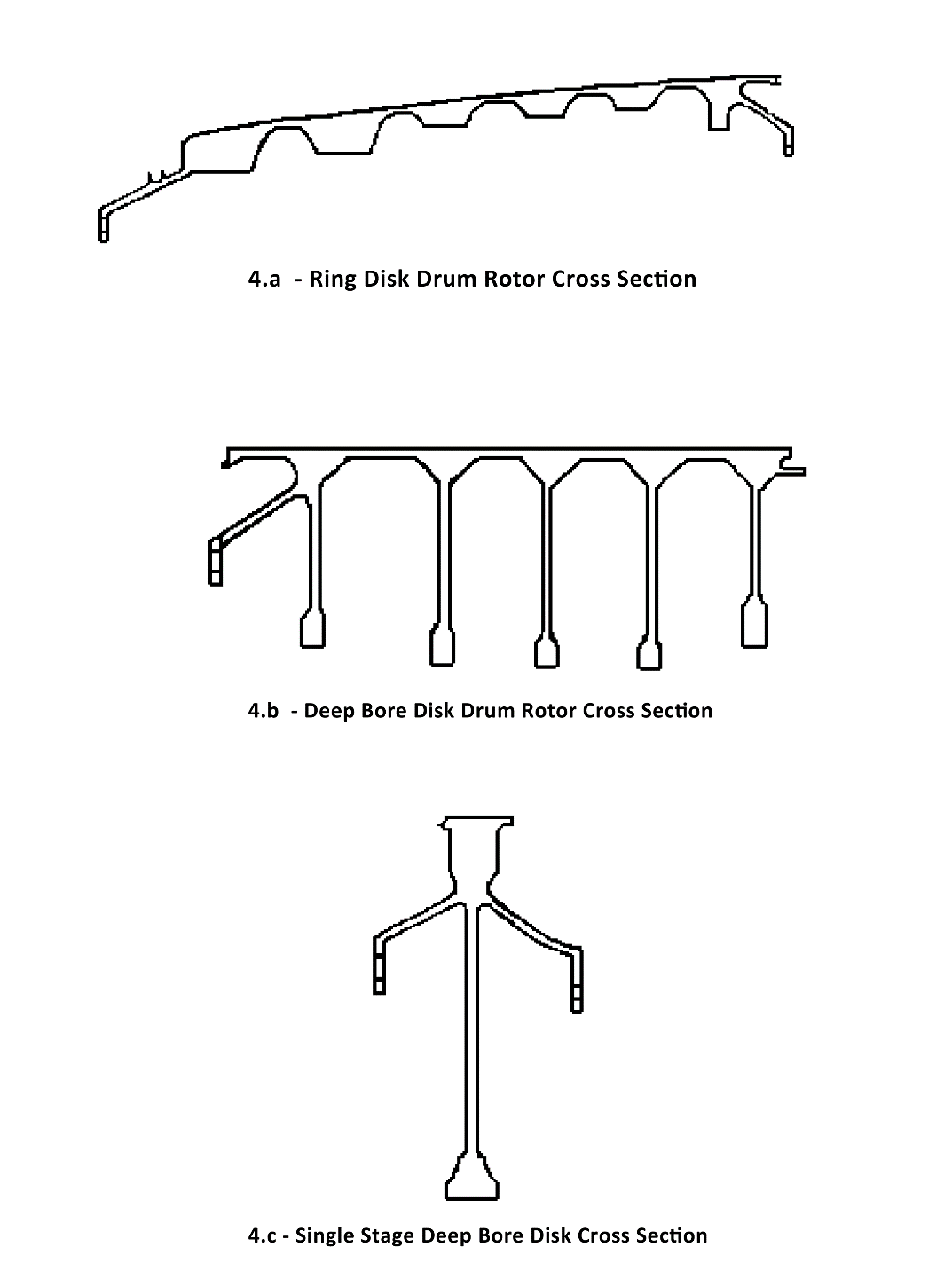

Fragment Hazard Model:

(A) Large Fragments

—

Ring

Disks (see Figure 4.a.) - Compressor drum rotors or spools with ring disks

have typically failed in a rim peeling mode when failure origins are in the

rim area. This type of failure

typically produces uncontained fragment energies, which are mitigated by a

single layer of conventional aluminium honeycomb structure. (Note: This

guidance material is based upon field experience and, as such, its application

should be limited to aluminium sheet and honeycomb fan reverser

construction. Typical construction

consists of 12.7 mm (a half inch) thickness of .003-.004” aluminium foil

honeycomb with .030" thick aluminium facing sheets. Alternative materials

and methods of construction should have at least equivalent impact energy

absorption characteristics). Failures

with the origins in the bore of these same drum sections have resulted in

fragments which can be characterised as a single 1/3 disk fragment and

multiple smaller fragments. The 1/3 disk fragment may or may not be contained

by the thrust reverser structure. The

remaining intermediate and small disk fragments, while escaping the engine

case, have been contained by the thrust reverser structure.

—

Deep

Bore Disks (see Figure 4.b.) and Single Disks (see Figure 4.c.) - For

compressor drum rotors or spools with deep bore disks, and single compressor

and turbine disks, the experience, while limited, indicates either a 1/3 and a

2/3 fragment, or a 1/3 fragment and multiple intermediate and small discrete fragments

should be considered. These fragments can be randomly released within an

impact area that ranges * 5 degrees from the plane of rotation.

(B) Small Fragments (Debris)

Consider

small fragments (reference AMC 20-128A, paragraph 9.d.) that could impact the

thrust reverser at * 15 degrees axial spread angle.

8.d.(4)(ii)

Minimisation:

Minimisation

guidance provided below is for fragments from axial flow rotors surrounded by

fan flow thrust reversers located over the intermediate or high-pressure core

rotors.

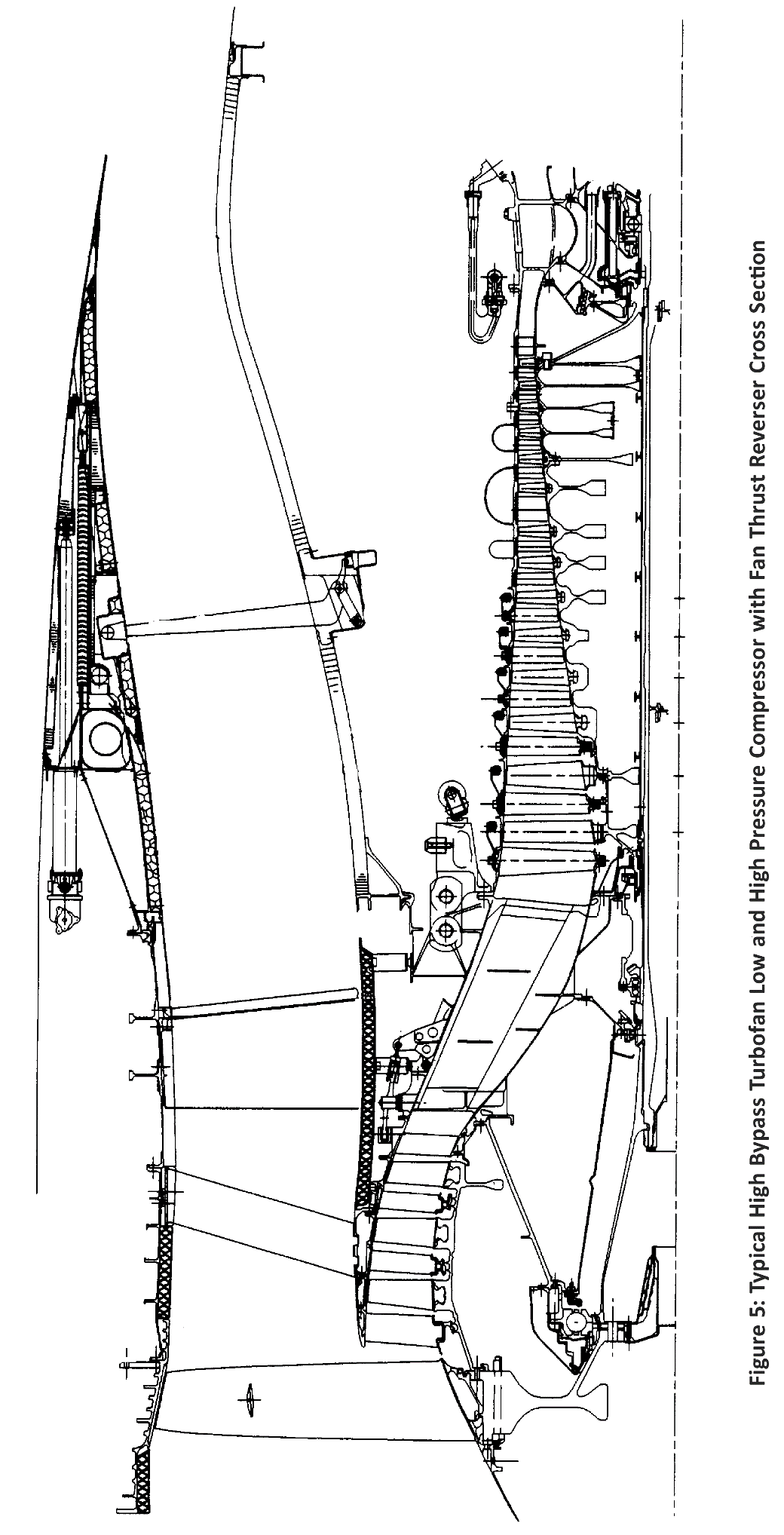

NOTE: See attached Figure 5: Typical High Bypass

Turbofan Low and High Pressure Compressor with Fan Thrust Reverser Cross

Section

(A) Large Fragments

For the

large fragments defined in Section 8.d.(4)(i)(A), above, the thrust reverser

retention systems should be redundant and separated as follows:

—

Ring

Disks Compressor Spools:

Retention

systems located in the outer barrel section of the thrust reverser should be

separated circumferentially (circumferential distance greater than the 1/3

disk fragment model as described in AMC20 128A) or axially (outside the * 5

degree impact area) so that a 1/3 disk segment can not damage all redundant

retention elements and allow thrust reversal (i.e., deployment of a door or

translating reverser sleeve half). Retention systems located between the inner

fan flow path wall and the engine casing should be located axially outside the

+ 5 degree impact area.

—

Deep-bore

Disk Spools and Single Disks:

Retention

systems should be separated axially with at least one retention element

located outside the * 5 degree impact area.

(B) Small Fragments

For the

small fragments defined in Section 8.d.(4)(i)(B), above, thrust reverser

retention systems should be provided with either:

—

At

least one retention element shielded in accordance with AMC 20-128A, paragraph

7(c), or capable of maintaining its retention capabilities after impact; or

—

One

retention element located outside the * 15 degree impact area.

9. «MIXED

CONTROLLABILITY / RELIABILITY» OPTION.

If the

aeroplane might experience an unwanted in-flight thrust reversal outside the

«controllable flight envelope» anytime during the entire operational life of

all aeroplanes of this type, then outside the controllable envelope

reliability compliance must be shown, taking into account associated risk

exposure time and the other considerations described in Section 8, above.

Conversely,

if reliability compliance is selected to be shown within a given limited

flight envelope with associated risk exposure time, then outside this envelope

controllability must be demonstrated taking into account the considerations

described in Section 7, above.

Mixed

controllability/reliability compliance should be shown in accordance with

guidance developed in Sections 7 and 8, above, respectively.

10. DEACTIVATED REVERSER.

The thrust

reverser system deactivation design should follow the same «fail-safe»

principles as the actuation system design, insofar as failure and

systems/hardware integrity. The effects

of thrust reverser system deactivation on other aeroplane systems, and on the

new configuration of the thrust reverser system itself, should be evaluated

according to Section 8.a., above. The location and load capability of the

mechanical lock-out system (thrust reverser structure and lock-out device)

should be evaluated according to Sections 8.b. and 8.d., above. The evaluation

should show that the level of safety associated with the deactivated thrust

reverser system is equivalent to or better than that associated with the

active system.

11. CS 25.933(b) COMPLIANCE.

For thrust

reversing systems intended for in-flight use, compliance with CS 25.933(b) may

be shown for unwanted in-flight thrust reversal, as appropriate, using the

methods specified in Sections 7 through 10, above.

12. CONTINUED AIRWORTHINESS.

12.a. Manufacturing/Quality: Due to the criticality of the thrust

reverser, manufacturing and quality assurance processes should be assessed and

implemented, as appropriate, to ensure the design integrity of the critical components.

12.b. Reliability Monitoring: An appropriate system should be implemented

for the purpose of periodic monitoring and reporting of in-service reliability

performance. The system should also

include reporting of in-service concerns related to design, quality, or

maintenance that have the potential of affecting the reliability of the thrust

reverser.

12.c. Maintenance and Alterations: The following material provides guidance for

maintenance designs and activity to assist in demonstrating compliance with

Sections 7 through 10, above (also reference CS 25.901(b)(2) and CS 25.1529/Appendix H). The criticality of the thrust

reverser and its control system requires that maintenance and maintainability

be emphasised in the design process and derivation of the maintenance control

program, as well as subsequent field maintenance, repairs, or alterations.

12.c.(1)

Design: Design aspects for providing adequate maintainability should address :

12.c.(1)(i)

Ease of maintenance. The following items should be taken into consideration:

—

It

should be possible to operate the thrust reverser for ground testing/trouble

shooting without the engine operating.

—

Lock-out

procedures (deactivation for flight) of the thrust reverser system should be

simple, and clearly described in the maintenance manual. Additionally, a

placard describing the procedure may be installed in a conspicuous place on

the nacelle.

—

Provisions

should be made in system design to allow easy and safe access to the

components for fault isolation, replacement, inspection, lubrication, etc. This

is particularly important where inspections are required to detect latent

failures. Providing safe access should

include consideration of risks both to the mechanic and to any critical design

elements that might be inadvertently damaged during maintenance.

—

Provisions

should be provided for easy rigging of the thrust reverser and adjustment of

latches, switches, actuators, etc.

12.c.(1)(ii)

Fault identification and elimination:

—

System

design should allow simple, accurate fault isolation and repair.

—

System

design personnel should be actively involved in the development,

documentation, and validation of the troubleshooting/fault isolation manual

and other maintenance publications. The systems design personnel should verify

that maintenance assumptions critical to any SSA conclusion are supported by

these publications (e.g., perform fault insertion testing to verify that the

published means of detecting, isolating, and eliminating the fault are

effective).

—

Thrust

reverser unstowed and unlocked indications should be easily discernible during

pre-flight inspections.

—

If

the aeroplane has onboard maintenance monitoring and recording systems, the

system should have provisions for storing all fault indications. This would be

of significant help to maintenance personnel in locating the source of

intermittent faults.

12.c.(1)(iii)

Minimisation of errors: Minimisation of errors during maintenance activity

should be addressed during the design process. Examples include physical

design features, installation orientation markings, dissimilar connections,

etc. The use of a formal «lessons learned»-based review early and often during

design development may help avoid repeating previous errors.

12.c.(1)(iv)

System Reliability: The design process should, where appropriate, use previous

field reliability data for specific and similar components to ensure system

design reliability.

12.c.(2) Maintenance Control:

12.c.(2)(i)

Maintenance Program: The development of the initial maintenance plan for the

aeroplane, including the thrust reverser, should consider, as necessary, the

following:

—

Involvement

of the manufacturers of the aeroplane, engine, and thrust reverser.

—

The

compatibility of the SSA information and the Maintenance Review Board Report,

Maintenance Planning Document, Master Minimum Equipment List, etc. (ref AMC 25.19).

—

Identification

by the manufacturer of all maintenance tasks critical to continued safe

flight. The operator should consider

these tasks when identifying and documenting Required Inspection Items.

—

The

complexity of lock-out procedures and appropriate verification.

—

Appropriate

tests, including an operational tests, of the thrust reverser to verify

correct system operation after the performance of any procedure that would

require removal, installation, or adjustment of a component; or disconnection

of a tube, hose, or electrical harness of the entire thrust reverser actuation

control system.

12.c.(2)(ii)

Training: The following considerations should be taken into account when

developing training documentation:

—

The

reason and the significance of accomplishing critical tasks as prescribed. This

would clarify why a particular task needs to be performed in a certain manner.

—

Instructions

or references as to what to do if the results of a check or operational test

do not agree with those given in the Aeroplane Maintenance Manual (AMM). The

manual should recommend some corrective action if a system fails a test or

check. This would help ensure that the

critical components are not overlooked in the trouble shooting process.

—

Emphasis

on the total system training by a single training source (preferably the

aeroplane manufacturer) to preclude fragmented information without a clear

system understanding. This training

concept should be used in the initial training and subsequent retraining.

—

Inclusion

of fault isolation and troubleshooting using the material furnished for the

respective manuals.

—

Evaluation

of the training materials to assure consistency between the training material

and the maintenance and troubleshooting manuals.

12.c.(2)(iii) Repairs and Alterations: The Instructions

for Continued Airworthiness essential to ensure that subsequent repairs or

alterations do not unintentionally violate the integrity of the original

thrust reverser system type design approval should be provided by the original

airframe manufacturer. Additionally, the original airframe manufacturer should

define a method of ensuring that this essential information will be evident to

those that may perform and approve such repairs and alterations. One example would be maintaining the wire

separation between relevant thrust reverser control electrical circuits. This

sensitivity could be communicated by statements in appropriate manuals such as

the Wiring Diagram Manual, and by decals or placards placed on visible areas

of the thrust reverser and/or aeroplane structure.

12.c.(2)(iv)

Feedback of Service Experience: The maintenance process should initiate the

feedback of service experience that will allow the monitoring of system

reliability performance and improvements in system design and maintenance

practices. Additionally, this service

experience should be used to assure the most current and effective formal

«lessons learned» design review process possible.

(A) Reliability Performance:

(Operators

and Manufacturers should collaborate on these items:)

—

Accurate

reporting of functional discrepancies.

—

Service

investigation of hardware by manufacturer to confirm and determine failure

modes and corrective actions if required.

—

Update

of failure rate data. (This will require co-ordination between the

manufacturers and airlines.)

(B) Improvements suggested by maintenance

experience:

(This will

provide data to effectively update these items:)

—

Manuals

—

Troubleshooting

—

Removal/replacement

procedures.

12.c.(2)(v)

Publications/Procedures: The following considerations should be addressed in

the preparation and revisions of the publications and procedures to support

the thrust reverser in the field in conjunction with CS 25.901(b)(2) and CS 25.1529(Appendix H).

(A) Documentation should be provided that

describes a rigging check, if required after adjustment of any thrust reverser

actuator drive system component.

(B) Documentation should be provided that

describes powered cycling of the thrust reverser to verify system integrity

whenever maintenance is performed. This

could also apply to any manual actuation of the reverser.

(C) The reasons and the significance of

accomplishing critical tasks should be included in the AMM.

(D) The AMM should include instructions or

references as to what to do if the results of a check or operational test do

not agree with those given in the AMM.

(E) Provisions should be made to address

inefficiencies and errors in the publications:

—

Identified

in the validation process of both critical and troubleshooting procedures.

—

Input

from field.

—

Operators

conferences.

(F) Development of the publications should be

a co-ordinated effort between the thrust reverser, engine, aeroplane

manufacturers and airline customers especially in the areas of:

—

AMM

—

Troubleshooting

—

Fault

isolation

—

Maintenance

data computer output

—

Procedure

Validation

—

Master

Minimum Equipment List

(G) Initial issue of the publication should

include the required serviceable limits for the complete thrust reverser

system.

13. FLIGHT CREW TRAINING.

In the case

of compliance with the «controllability option,» and when the nature of the

in-flight thrust reversal is judged as unusual (compared to expected

consequences on the aeroplane of other failures, both basic and recurrent),

flight crew training should be considered on a training simulator

representative of the aeroplane, that is equipped with thrust reverser

in-flight modelisation to avoid flight crew misunderstandings:

13.a. Transient manoeuvre: Recovery from the

unwanted in-flight thrust reversal.

13.b Continued flight and landing: Manoeuvring

appropriate to the recommended procedure (included trim and unattended

operation) and precision tracking (ILS guide slope tracking, speed/altitude

tracking, etc.).

Figure 4 - Generic Disk and Rotor

terminology used in interim thrust reverser guidance material for minimizing

the hazard from engine rotor burst

[Amdt No:

25/1]

[Amdt

No: 25/24]