AMC 25.1309 System design and analysis

ED

Decision 2021/015/R

Table

of Contents

1. PURPOSE

2. RESERVED

3. RELATED DOCUMENTS

a. Advisory Circulars,

Acceptable Means of Compliance

b. Industry Documents

4. APPLICABILITY OF CS

25.1309

5. DEFINITIONS

6. BACKGROUND

a. General

b. Fail-Safe Design Concept

c. Development of Aeroplane

and System Functions

7. FAILURE CONDITION

CLASSIFICATIONS AND PROBABILITY TERMS

a. Classifications

b. Qualitative Probability

Terms

c. Quantitative Probability

Terms

8. SAFETY OBJECTIVE

9. COMPLIANCE WITH CS

25.1309

a. Compliance with CS

25.1309(a)

b. Compliance with CS

25.1309(b)

(1) General

(2) Planning

(3) Availability of Industry

Standards and Guidance Materials

(4) Acceptable Application of

Development Assurance Methods

(5) Crew and Maintenance

Actions

(6) Significant Latent

Failures

c. Compliance with CS

25.1309(c)

10. IDENTIFICATION OF FAILURE

CONDITIONS AND CONSIDERATIONS WHEN ASSESSING THEIR EFFECTS

a. Identification of Failure

Conditions

b. Identification of Failure

Conditions Using a Functional Hazard Assessment

c. Considerations When

Assessing Failure Condition Effects

11. ASSESSMENT OF FAILURE

CONDITION PROBABILITIES AND ANALYSIS CONSIDERATIONS

a. Assessment of Failure

Condition Probabilities

b. Single Failure

Considerations

c. Common-Cause Failure

Considerations

d. Depth of Analysis

e. Calculation of Average

Probability per Flight Hour (Quantitative Analysis)

f. Integrated Systems

g. Operational or

Environmental Conditions

h. Justification of

Assumptions, Data Sources and Analytical Techniques

12. OPERATIONAL AND

MAINTENANCE CONSIDERATIONS

a. Flight Crew Action

b. Maintenance Action

c. Candidate Certification

Maintenance Requirements

d. Flight with Equipment or

Functions known to be Inoperative

13. ASSESSMENT OF

MODIFICATIONS TO PREVIOUSLY CERTIFIED AEROPLANES

APPENDIX 1. ASSESSMENT METHODS

APPENDIX 2. SAFETY ASSESSMENT PROCESS OVERVIEW

APPENDIX 3. CALCULATION OF THE AVERAGE PROBABILITY PER FLIGHT HOUR

APPENDIX 4. ALLOWABLE PROBABILITIES

APPENDIX 5. EXAMPLE OF LIMIT LATENCY AND RESIDUAL PROBABILITY ANALYSIS

1. PURPOSE.

a. This AMC describes acceptable means for

showing compliance with the requirements of CS 25.1309.

These means are intended to provide guidance to supplement the engineering and

operational judgement that must form the basis of any compliance

demonstration.

b. The extent to which the more structured

methods and guidelines contained in this AMC should be applied is a function

of systems complexity and systems failure consequence. In general, the extent

and structure of the analyses required to show compliance with CS 25.1309 will be greater when the system is more complex and the effects of the

Failure Conditions are more severe. This AMC is not intended to require that

the more structured techniques introduced in this revision be applied where

traditional techniques have been shown to be acceptable for more traditional

systems designs. The means described in this AMC are not mandatory. Other

means may be used if they show compliance with CS 25.1309.

2. RESERVED.

3. RELATED DOCUMENTS.

The

following guidance and advisory materials are referenced herein:

a. Advisory Circulars,

Acceptable Means of Compliance.

(1) AMC 25.1322 Alerting Systems.

(2) AC 25.19/AMC 25.19

Certification Maintenance Requirements.

(3) AMC 20-115 Software Considerations for

Airborne Systems and Equipment Certification

(4) AMC 25.901(c) Safety Assessment of Powerplant

Installations.

b. Industry documents.

(1) RTCA, Inc., Document No. DO-160D/EUROCAE

ED-14G, Environmental Conditions and Test Procedures for Airborne Equipment.

(2) Society of Automotive Engineers (SAE)

Aerospace Recommended Practice (ARP) 4754A/EUROCAE ED-79A, Guidelines for

development of civil aircraft and systems.

(3) Society of Automotive Engineers (SAE)

Aerospace Recommended Practice (ARP) 4761, Guidelines and Methods for

Conducting the Safety Assessment Process on Civil Airborne Systems and

Equipment.

4. APPLICABILITY OF CS 25.1309.

Paragraph 25.1309 is

intended as a general requirement that should be applied to any equipment or

system as installed, in addition to specific systems requirements, except as

indicated below.

a. While CS 25.1309

does not apply to the performance and flight characteristics of Subpart B and

structural requirements of Subparts C and D, it does apply to any system on

which compliance with any of those requirements is based. For example, it does

not apply to an aeroplane's inherent stall characteristics or their

evaluation, but it does apply to a stall warning system used to enable

compliance with CS 25.207.

b. Jams of

flight control surfaces or pilot controls that are covered by CS 25.671(c)(3) are excepted from the

requirements of CS 25.1309(b)(1)(ii).

c. Certain single failures covered by CS 25.735(b)(1) are excepted from the requirements of CS 25.1309(b).

The reason concerns the brake system requirement that limits the effect of a

single failure to doubling the brake roll stopping distance. This requirement

has been shown to provide a satisfactory level of safety without the need to

analyse the particular circumstances and conditions under which the single

failure occurs.

d. The failure conditions covered by CS 25.810

and CS 25.812 are excepted from the requirements of CS 25.1309(b).

These failure conditions related to loss of function are associated with

varied evacuation scenarios for which the probability cannot be determined. It

has not been proven possible to define appropriate scenarios under which

compliance with CS 25.1309(b) can be demonstrated. It is therefore

considered more practical to require particular design features or specific

reliability demonstrations as described in CS 25.810

and CS 25.812. Traditionally, this approach has been found

to be acceptable.

e. The requirements of CS 25.1309

are generally applicable to engine, propeller, and propulsion system

installations. The specific applicability and exceptions are stated in CS 25.901(c).

f. Some systems and some functions already

receive an evaluation to show compliance with specific requirements for

specific failure conditions and, therefore, meet the intent of CS 25.1309 without the need for additional analysis for those specific failure conditions.

g. The safety assessment process should

consider all phases during flight and on ground when the aeroplane is in

service. While this includes the conditions associated with the pre-flight

preparation, embarkation and disembarkation, taxi phase, etc., it, therefore,

does not include periods of shop maintenance, storage, or other out-of-service

activities.

Where

relevant, the effects on persons other than the aeroplane occupants should be

taken into account when assessing failure conditions in compliance with CS

25.1309.

5. DEFINITIONS.

The

following definitions apply to the system design and analysis requirements of CS 25.1309

and the guidance material provided in this AMC. They should not be assumed to

apply to the same or similar terms used in other regulations or AMCs. Terms

for which standard dictionary definitions apply are not defined herein.

a. Analysis.

The terms "analysis" and "assessment" are used throughout.

Each has a broad definition and the two terms are to some extent

interchangeable. However, the term analysis generally implies a more specific,

more detailed evaluation, while the term assessment may be a more general or

broader evaluation but may include one or more types of analysis. In practice,

the meaning comes from the specific application, e.g., fault tree analysis,

Markov analysis, Preliminary System Safety Assessment, etc.

b. Assessment.

See the definition of analysis above.

c. At-Risk

Time. The period of time during which an item must fail in order to cause

the failure effect in question. This is usually associated with the final

fault in a fault sequence leading to a specific failure condition.

d. Average

Probability Per Flight Hour. For the purpose of this AMC, is a

representation of the number of times the subject Failure Condition is

predicted to occur during the entire operating life of all aeroplanes of the

type divided by the anticipated total operating hours of all aeroplanes of

that type (Note: The Average Probability Per Flight Hour is normally

calculated as the probability of a Failure Condition occurring during a

typical flight of mean duration divided by that mean duration).

e. Candidate

Certification Maintenance Requirements (CCMR). A periodic maintenance or

flight crew check may be used in a safety analysis to help demonstrate

compliance with CS 25.1309(b) for hazardous and catastrophic failure conditions.

Where such checks cannot be accepted as basic servicing or airmanship they

become Candidate Certification Maintenance Requirements (CCMRs). AMC 25.19 defines a method by which Certification Maintenance Requirements

(CMRs) are identified from the candidates. A CMR becomes a required periodic

maintenance check identified as an operating limitation of the type

certificate for the aeroplane.

f. Check.

An examination (e.g., an inspection or test) to determine the physical

integrity and/or functional capability of an item.

g. Complex.

A system is Complex when its operation, failure modes, or failure effects are

difficult to comprehend without the aid of analytical methods.

h. Complexity.

An attribute of functions, systems or items, which makes their operation,

failure modes, or failure effects difficult to comprehend without the aid of

analytical methods.

i. Conventional.

A system is considered to be Conventional if its functionality, the

technological means used to implement its functionality, and its intended

usage are all the same as, or closely similar to, that of previously approved

systems that are commonly-used.

j. Design

Appraisal. This is a qualitative appraisal of the integrity and safety of

the system design.

k. Development

Assurance. All those planned and systematic actions used to substantiate,

to an adequate level of confidence, that errors in requirements, design, and

implementation have been identified and corrected such that the system

satisfies the applicable certification basis.

l. Development Error. A mistake in

requirements, design, or implementation.

m. Error.

An omission or incorrect action by a crewmember or maintenance personnel, or a

development error (e.g. mistake in requirements determination, design, or

implementation).

n. Event.

An occurrence which has its origin distinct from the aeroplane, such as

atmospheric conditions (e.g. gusts, temperature variations, icing and

lightning strikes), runway conditions, conditions of communication,

navigation, and surveillance services, bird-strike, cabin and baggage fires.

The term is not intended to cover sabotage.

o. Exposure

Time. The period of time between the time when an item was last known to

be operating properly and the time when it will be known to be operating

properly again.

p. Failure.

An occurrence, which affects the operation of a component, part, or element

such that it can no longer function as intended, (this includes both loss of

function and malfunction). Note: Errors may cause Failures, but are not

considered to be Failures.

q. Failure

Condition. A condition having an effect on the aeroplane and/or its

occupants, either direct or consequential, which is caused or contributed to

by one or more failures or errors, considering flight phase and relevant

adverse operational or environmental conditions, or external events.

r. Installation

Appraisal. This is a qualitative appraisal of the integrity and safety of

the installation. Any deviations from normal, industry-accepted installation

practices, such as clearances or tolerances, should be evaluated, especially

when appraising modifications made after entry into service.

s. Item. A hardware or software element

having bounded and well-defined interfaces.

t. Latent

Failure. A failure is latent until it is made known to the flight crew or

maintenance personnel.

u. Qualitative.

Those analytical processes that assess system and aeroplane safety in an

objective, nonnumerical manner.

v. Quantitative.

Those analytical processes that apply mathematical methods to assess system

and aeroplane safety.

w. Redundancy.

The presence of more than one independent means for accomplishing a given

function or flight operation.

x. Significant

Latent Failure. A latent failure that would, in combination with one or

more specific failure(s) or event(s), result in a hazardous or catastrophic

failure condition.

y. System.

A combination of interrelated items arranged to perform one or more specific

functions.

6. BACKGROUND

a. General

For a number

of years aeroplane systems were evaluated to specific requirements, to the "ʽsingle

fault’" criterion, or to the fail-safe design concept. As

later-generation aeroplanes developed, more safety-critical functions were

required to be performed, which generally resulted in an increase in the

complexity of the systems designed to perform these functions. The potential

hazards to the aeroplane and its occupants which could arise in the event of

loss of one or more functions provided by a system or that system's

malfunction had to be considered, as also did the interaction between systems

performing different functions. This has led to the general principle that an

inverse relationship should exist between the probability of a failure

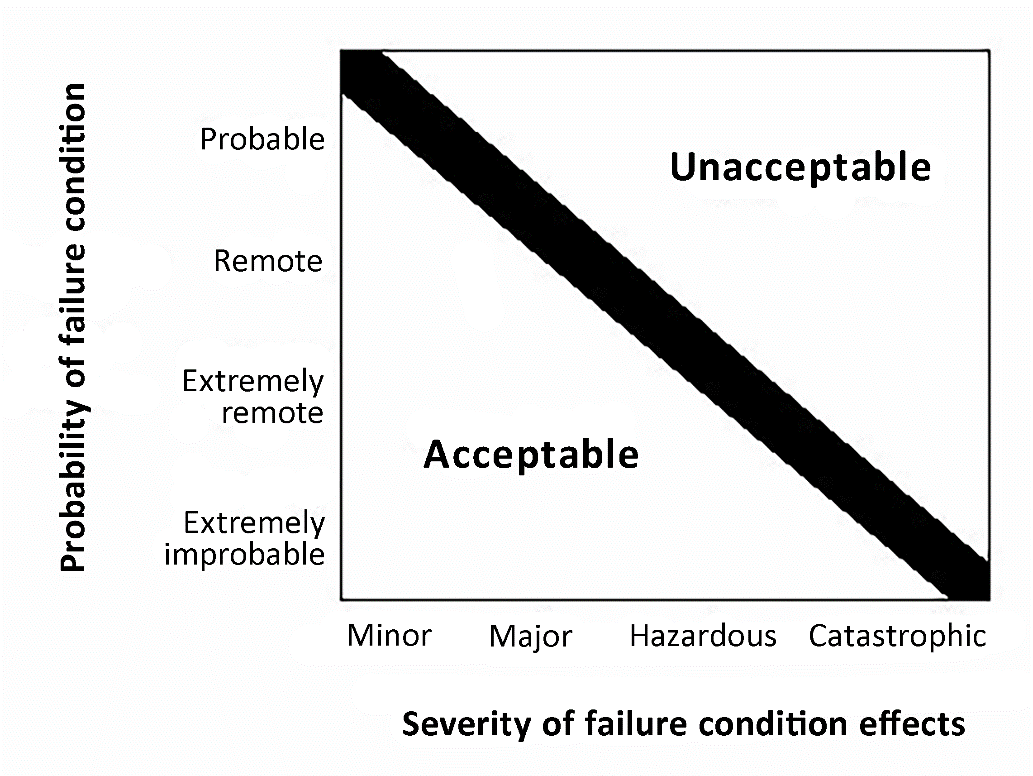

condition and its effect on the aeroplane and/or its occupants (see Figure 1).

In assessing the acceptability of a design it was recognised that rational

probability values would have to be established. Historical evidence indicated

that the probability of a serious accident due to operational and

airframe-related causes was approximately one per million hours of flight.

Furthermore, about 10 % of the total were attributed to failure

conditions caused by the aeroplane's systems. It seems reasonable that serious

accidents caused by systems should not be allowed a higher probability than

this in new aeroplane designs. It is reasonable to expect that the probability

of a serious accident from all such failure conditions be not greater than one

per ten million flight hours or 1 × 10-7 per flight hour for a

newly designed aeroplane. The difficulty with this is that it is not possible

to say whether the target has been met until all the systems on the aeroplane

are collectively analysed numerically. For this reason it was assumed, arbitrarily,

that there are about one hundred potential failure conditions in an aeroplane,

which could be Ccatastrophic. The target allowable average probability

per flight hour of 1 × 10-7 was thus apportioned equally among

these failure conditions, resulting in an allocation of not greater than 1 ×

10-9 to each. The upper limit for the average probability per

flight hour for catastrophic failure conditions would be 1 × 10-9,

which establishes an approximate probability value for the term ʽextremely

improbable’. Failure conditions having less severe effects could be relatively

more likely to occur.

b. Fail-Safe Design

Concept.

The CS-25

airworthiness standards are based on, and incorporate, the objectives and

principles or techniques of the fail-safe design concept, which considers the

effects of failures and combinations of failures in defining a safe design.

(1) The following basic objectives pertaining

to failures apply:

(i) In any system or subsystem, the failure

of any single element, component, or connection during any one flight should

be assumed, regardless of its probability. Such single failures should not be

catastrophic.

(ii) Subsequent failures of related systems

during the same flight, whether detected or latent, and combinations thereof,

should also be considered.

(2) The fail-safe design concept uses the

following design principles or techniques in order to ensure a safe design.

The use of only one of these principles or techniques is seldom adequate. A

combination of two or more is usually needed to provide a fail-safe design;

i.e. to ensure that major failure conditions are remote, hazardous failure

conditions are extremely remote, and catastrophic failure conditions are

extremely improbable:

(i) Designed

Integrity and Quality, including Life

Limits, to ensure intended function and prevent failures.

(ii) Redundancy

or Backup Systems to enable

continued function after any single (or other defined number of) failure(s);

e.g., two or more engines, hydraulic systems, flight control systems, etc.

(iii) Isolation

and/or Segregation of Systems, Components, and Elements so that the

failure of one does not cause the failure of another.

(iv) Proven

Reliability so that multiple, independent failures are unlikely to occur

during the same flight.

(v) Failure

Warning or Indication to provide detection.

(vi) Flight

crew Procedures specifying corrective action for use after failure

detection.

(vii) Checkability:

the capability to check a component's condition.

(viii) Designed

Failure Effect Limits, including the capability to sustain damage, to

limit the safety impact or effects of a failure.

(ix) Designed

Failure Path to control and direct the effects of a failure in a way that

limits its safety impact.

(x) Margins

or Factors of Safety to allow for any undefined or unforeseeable adverse

conditions.

(xi) Error-Tolerance

that considers adverse effects of foreseeable errors during the aeroplane's

design, test, manufacture, operation, and maintenance.

c. Development of Aeroplane and System

Functions.

(1) A concern arose regarding the efficiency

and coverage of the techniques used for assessing safety aspects of aeroplane

and systems functions implemented through the use of electronic technology and

software-based techniques. The concern is that design and analysis techniques

traditionally applied to deterministic risks or to conventional, non-complex

systems may not provide adequate safety coverage for these aeroplane and

system functions. Thus, other assurance techniques, such as development

assurance utilising a combination of integral processes (e.g. process

assurance, configuration management, requirement validation and implementation

verification), or structured analysis or assessment techniques applied at the

aeroplane level and across integrated or interacting systems, have been

requested. Their systematic use increases confidence that development errors

and integration or interaction effects have been adequately identified and

corrected.

(2) Considering the above developments, as

well as revisions made to the CS 25.1309, this AMC was revised to include

new approaches, both qualitative and quantitative, which may be used to assist

in determining safety requirements and establishing compliance with these

requirements, and to reflect revisions in the rule, considering the whole

aeroplane and its systems. It also provides guidance for determining when, or

if, particular analyses or development assurance actions should be conducted

in the frame of the development and safety assessment processes. Numerical

values are assigned to the probabilistic terms included in the requirements

for use in those cases where the impact of system failures is examined by

quantitative methods of analysis. The analytical tools used in determining

numerical values are intended to supplement, but not replace, qualitative

methods based on engineering and operational judgement.

7. FAILURE CONDITION

CLASSIFICATIONS AND PROBABILITY TERMS

a. Classifications.

Failure

conditions may be classified according to the severity of their effects as

follows:

(1) No

Safety Effect: Failure conditions that would have no effect on safety; for

example, failure conditions that would not affect the operational capability

of the aeroplane or increase crew workload.

(2) Minor:

Failure conditions which would not significantly reduce aeroplane safety, and

which involve crew actions that are well within their capabilities. Minor

failure conditions may include, for example, a slight reduction in safety

margins or functional capabilities, a slight increase in crew workload, such

as routine flight plan changes, or some physical discomfort to passengers or

cabin crew.

(3) Major:

Failure conditions which would reduce the capability of the aeroplane or the

ability of the crew to cope with adverse operating conditions to the extent

that there would be, for example, a significant reduction in safety margins or

functional capabilities, a significant increase in crew workload or in

conditions impairing crew efficiency, or discomfort to the flight crew, or

physical distress to passengers or cabin crew, possibly including injuries.

(4) Hazardous:

Failure conditions, which would reduce the capability of the aeroplane

or the ability of the crew to cope with adverse operating, conditions

to the extent that there would be:

(i) A large reduction in safety margins or

functional capabilities;

(ii) Physical distress or excessive workload

such that the flight crew cannot be relied upon to perform their tasks

accurately or completely; or

(iii) Serious or fatal injury to a relatively

small number of the occupants other than the flight crew.

(5) Catastrophic:

Failure conditions, which would result in multiple fatalities, usually

with the loss of the aeroplane.

(Note: A

failure condition which would prevent continued safe flight and landing should

be classified catastrophic unless otherwise defined in other specific AMCs.

For flight control systems, continued safe flight and landing is defined in AMC 25.671, paragraphs 4 and 7.)

b. Qualitative Probability Terms.

When using

qualitative analyses to determine compliance with CS 25.1309(b),

the following descriptions of the probability terms used in CS 25.1309

and this AMC have become commonly accepted as aids to engineering judgement:

(1) Probable failure conditions are those

anticipated to occur one or more times during the entire operational life of

each aeroplane.

(2) Remote failure conditions are those

unlikely to occur to each aeroplane during its total life, but which may occur

several times when considering the total operational life of a number of

aeroplanes of the type.

(3) Extremely remote failure conditions are

those not anticipated to occur to each aeroplane during its total life but

which may occur a few times when considering the total operational life of all

aeroplanes of the type.

(4) Extremely improbable failure conditions

are those so unlikely that they are not anticipated to occur during the entire

operational life of all aeroplanes of one type.

c. Quantitative Probability Terms.

When using

quantitative analyses to help determine compliance with CS 25.1309(b),

the following descriptions of the probability terms used in this requirement

and this AMC have become commonly accepted as aids to engineering judgement.

They are expressed in terms of acceptable ranges for the average probability

per flight hour.

(1) Probability Ranges.

(i) Probable failure conditions are those

having average probability per flight hour greater than of the order of 1 × 10-5.

(ii) Remote failure conditions are those having

an average probability per flight hour of the order of 1 × 10-5 or

less, but greater than of the order of 1 × 10-7.

(iii) Extremely remote failure conditions are

those having an average probability per flight hour of the order of 1 × 10-7

or less, but greater than of the order of 1 × 10-9.

(iv) Extremely improbable failure conditions

are those having an average probability per flight hour of the order of 1 × 10-9

or less.

8. SAFETY OBJECTIVE.

a. The objective of CS 25.1309

is to ensure an acceptable safety level for equipment and systems as installed

on the aeroplane. A logical and acceptable inverse relationship must exist

between the average probability per

flight hour and the severity of failure

condition effects, as shown in Figure 1, such that:

(1) Failure conditions with no safety effect have no probability requirement.

(2) Minor failure conditions may be probable.

(3) Major failure conditions must be no more frequent than remote.

(4) Hazardous failure conditions must be no more frequent than extremely

remote.

(5) Catastrophic failure conditions must be extremely improbable.

Figure

1: Relationship between Probability and Severity of Failure Condition Effects

b. The classification of the failure conditions

associated with the severity of their effects are described in Figure 2a.

The safety objectives associated with failure

conditions are described in Figure 2b.

Figure 2a: Relationship Between Severity of the

Effects and Classification of Failure Conditions

|

Severity of the Effects |

Effect on Aeroplane |

No effect on operational capabilities or

safety |

Slight reduction in functional

capabilities or safety margins |

Significant reduction in functional

capabilities or safety margins |

Large reduction in functional

capabilities or safety margins |

Normally with hull loss |

|

Effect on Occupants excluding Flight

Crew |

Inconvenience |

Physical discomfort |

Physical distress, possibly including

injuries |

Serious or fatal injury to a small

number of passengers or cabin crew |

Multiple fatalities |

|

|

Effect on Flight Crew |

No effect on flight crew |

Slight increase in workload |

Physical discomfort or a significant

increase in workload |

Physical distress or excessive workload

impairs ability to perform tasks |

Fatalities or incapacitation |

|

|

Classification of Failure Conditions |

No Safety Effect |

Minor |

Major |

Hazardous |

Catastrophic |

|

Figure 2b: Relationship Between Classification of

Failure Conditions and Probability

|

Classification of Failure Conditions |

No Safety Effect |

Minor |

Major |

Hazardous |

Catastrophic |

|

Allowable Qualitative Probability |

No Probability Requirement |

<-Probable-> |

<--Remote--> |

Extremely <--------------> Remote |

Extremely Improbable |

|

Allowable Quantitative Probability:

Average Probability per Flight Hour on the Order of: |

No Probability Requirement |

<--------------> <10-3 Note 1 |

<--------------> <10-5 |

<--------------> <10-7 |

<10-9 |

|

Note 1: A numerical probability range is provided

here as a reference. The applicant is not required to perform a quantitative

analysis, nor substantiate by such an analysis, that this numerical criteria

has been met for Minor Failure Conditions. Current transport category

aeroplane products are regarded as meeting this standard simply by using

current commonly‑accepted industry practice. |

|||||

c. The safety objectives associated with

catastrophic failure conditions must

be satisfied by demonstrating that:

(1) No single failure will result in a

catastrophic failure condition;

and

(2) Each catastrophic failure condition is extremely improbable; and

(3) Given that a single latent failure has

occurred on a given flight, each catastrophic failure condition, resulting

from two failures, either of which is latent for more than one flight, is

remote.

9. COMPLIANCE WITH CS 25.1309.

This

paragraph describes specific means of compliance for CS 25.1309.

The applicant should obtain early concurrence of the certification authority

on the choice of an acceptable means of compliance.

a. Compliance with CS 25.1309(a).

(1) Equipment covered by CS 25.1309(a)(1) must

be shown to function properly when installed. The aeroplane operating and

environmental conditions over which proper functioning of the equipment,

systems, and installation is required to be considered includes the full

normal envelope of the aeroplane as defined by the Aeroplane Flight Manual

operating limitations together with any modification to that envelope

associated with abnormal or emergency procedures. Other external environmental

conditions such as atmospheric turbulence, HIRF, lightning, and precipitation,

which the aeroplane is reasonably expected to encounter, should also be

considered. The severity of the external environmental conditions, which

should be considered, are limited to those established by certification

standards and precedence.

(2) In addition to the external operating and

environmental conditions, the effect of the environment within the aeroplane

should be considered. These effects should include vibration and acceleration

loads, variations in fluid pressure and electrical power, fluid or vapour

contamination, due either to the normal environment or accidental leaks or

spillage and handling by personnel. Document referenced in paragraph 3b(1)

defines a series of standard environmental test conditions and procedures,

which may be used to support compliance. Equipment covered by (CS) Technical

Standard Orders containing environmental test procedures or equipment

qualified to other environmental test standards can be used to support

compliance. The conditions under which the installed equipment will be

operated should be equal to or less severe than the environment for which the

equipment is qualified.

(3) The required substantiation of the proper

functioning of equipment, systems, and installations under the operating and

environmental conditions approved for the aeroplane may be shown by test

and/or analysis or reference to comparable service experience on other

aeroplanes. It must be shown that the comparable service experience is valid

for the proposed installation. For the equipment systems and installations

covered by CS 25.1309(a)(1), the compliance demonstration

should also confirm that the normal functioning of such equipment, systems,

and installations does not interfere with the proper functioning of other

equipment, systems, or installations covered by CS 25.1309(a)(1).

(4) The equipment, systems, and installations

covered by CS 25.1309(a)(2) are typically those

associated with amenities for passengers such as passenger entertainment

systems, in-flight telephones, etc., whose failure or improper functioning in

itself should not affect the safety of the aeroplane. Operational and

environmental qualification requirements for those equipment, systems, and

installations are reduced to the tests that are necessary to show that their

normal or abnormal functioning does not adversely affect the proper

functioning of the equipment, systems, or installations covered by CS

25.1309(a)(1) and does not otherwise adversely influence the safety of the

aeroplane or its occupants. Examples of adverse influences are: fire,

explosion, exposing passengers to high voltages, etc. Normal installation

practices should result in sufficiently obvious isolation so that

substantiation can be based on a relatively simple qualitative installation

evaluation. If the possible impacts, including failure modes or effects, are

questionable, or isolation between systems is provided by complex means, more

formal structured evaluation methods may be necessary.

b. Compliance with CS 25.1309(b).

Paragraph 25.1309(b)

requires that the aeroplane systems and associated components, considered

separately and in relation to other systems, must be designed so that any

catastrophic failure condition

is extremely improbable and does not result from a single failure. It also

requires that any hazardous failure

condition is extremely remote, and that any major failure condition is remote. An

analysis should always consider the application of the fail-safe design

concept described in paragraph 6.b, and give special attention to ensuring the

effective use of design techniques that would prevent single failures or other

events from damaging or otherwise adversely affecting more than one redundant

system channel or more than one system performing operationally similar

functions.

(1) General.

Compliance with the requirements of CS 25.1309(b) should be shown by analysis and,

where necessary, by appropriate ground, flight, or simulator tests. Failure conditions should be identified and

their effects assessed. The maximum allowable probability of the occurrence of

each failure condition is

determined from the failure condition’s

effects, and when assessing the probabilities of failure conditions, appropriate analysis considerations should be

accounted for. Any analysis must consider:

(i)

Possible failure conditions and

their causes, modes of failure, and damage from sources external to the

system.

(ii) The possibility of multiple failures and

undetected failures.

(iii) The possibility of requirement, design and

implementation errors.

(iv) The effect of reasonably anticipated crew

errors after the occurrence of a failure or failure condition.

(v) The effect of reasonably anticipated

errors when performing maintenance actions.

(vi) The crew alerting cues, corrective action

required, and the capability of detecting faults.

(vii) The resulting effects on the aeroplane and

occupants, considering the stage of flight, the sequence of events/failures

occurrence when relevant, and operating and environmental conditions.

(2) Planning. This

AMC provides guidance on methods of accomplishing the safety objective. The

detailed methodology needed to achieve this safety objective will depend on

many factors, in particular the degree of systems complexity and integration.

For aeroplanes containing many complex or integrated systems, it is likely

that a plan will need to be developed to describe the intended process. This

plan should include consideration of the following aspects:

(i) Functional and physical

interrelationships of systems.

(ii) Determination of detailed means of

compliance, which should include development assurance activities.

(iii) Means for establishing the accomplishment

of the plan.

(3) Availability

of Industry Standards and Guidance Materials. There are a variety of

acceptable techniques currently being used in industry, which may or may not

be reflected in the documents referenced in paragraphs 3.b(2) and 3.b(3). This

AMC is not intended to compel the use of these documents during the definition

of the particular method of satisfying the objectives of this AMC. However,

these documents do contain material and methods of performing the system

safety assessment. These methods, when correctly applied, are recognised by

EASA as valid for showing compliance with CS 25.1309(b). In addition, the Document referenced in paragraph 3.b(3) contains

tutorial information on applying specific engineering methods (e.g. Markov

analysis, fault tree analysis) that may be utilised in whole or in part.

(4) Acceptable

Application of Development Assurance Methods. Paragraph 9.b(1)(iii) above

requires that any analysis necessary to demonstrate compliance with CS 25.1309(b)

must consider the possibility of development errors. Errors made during the

design and development of systems have traditionally been detected and

corrected by exhaustive tests conducted on the system and its components, by

direct inspection, and by other direct verification methods capable of

completely characterising the performance of the system. These direct

techniques may still be appropriate for systems containing non-complex items

(i.e. items that are fully assured by a combination of testing and analysis)

that perform a limited number of functions and that are not highly integrated

with other aeroplane systems. For more complex or integrated systems,

exhaustive testing may either be impossible because all of the system states

cannot be determined or impractical because of the number of tests that must

be accomplished. For these types of systems, compliance may be demonstrated by

the use of development assurance. The level of development assurance (function

development assurance level (FDAL)/item development assurance level (IDAL))

should be commensurate with the severity of the failure conditions the system is contributing to.

Guidelines,

which may be used for the assignment of development assurance levels to

aeroplanes and system functions (FDAL) and to items (IDAL), are described in

the Document referenced in 3.b(2) above. Through this Document, EASA

recognises that credit can be taken from system architecture (e.g. functional

or item development independence) for the FDAL/IDAL assignment process.

Guidelines,

which may be used for providing development assurance, are described for

aeroplane and system development in the Document referenced in 3.b(2), and for

software in the Document referenced in 3.a(3) above. (There is currently no

agreed development assurance standard for airborne electronic hardware.)

(5) Crew and Maintenance

Actions.

(i) Where an analysis identifies some

indication to, and/or action by, the flight crew, cabin crew, or maintenance

personnel, the following activities should be accomplished:

1 Verify that any identified indications

are actually provided by the system. This includes the verification that the

elements that provide detection (e.g. sensors, logic) properly trigger the

indication under the relevant situations considering various causes, flight

phases, operating conditions, operational sequences, and environments.

2 Verify that any identified indications

will, in fact, be recognised.

3 Verify that any actions required have a

reasonable expectation of being accomplished successfully and in a timely

manner.

(ii) These verification activities should be

accomplished by consulting with engineers, pilots, flight attendants,

maintenance personnel, and human factors specialists, as appropriate, taking

due consideration of any relevant service experience and the consequences if

the assumed action is not performed or performed improperly.

(iii) In complex situations, the results of the

review by specialists may need to be confirmed by simulator, ground tests, or

flight tests. However, quantitative assessments of the probabilities of crew

or maintenance errors are not currently considered feasible. If the failure

indications are considered to be recognisable and the required actions do not

cause an excessive workload, then for the purposes of the analysis, such

corrective actions can be considered to be satisfactorily accomplished. If the

necessary actions cannot be satisfactorily accomplished, the tasks and/or the

systems need to be modified.

(6) Significant Latent

Failures.

(i) Compliance with CS 25.1309(b)(4)

For

compliance with CS 25.1309(b)(4), the hereafter systematic approach should be

followed:

1. The applicant must first eliminate

significant latent failures to the maximum practical extent utilising the

current state-of-the-art technology, e.g. implement practical and reliable

failure monitoring and flight crew indication systems to detect failures that

would otherwise be latent for more than one flight. Additional guidance is

provided in AMC 25-19 Section 8, Design Considerations Related to

Significant Latent Failures.

2. For each significant latent failure

which cannot reasonably be eliminated, the applicant must minimise the

exposure time by design utilising current state-of-the-art technology rather

than relying on scheduled maintenance tasks at lengthy intervals, i.e.

implementing pilot-initiated checks, or self-initiated checks (e.g. first

flight of the day check, power-up built-in tests, other system automated

checks).

3. When relying on scheduled maintenance

tasks, quantitative as well as qualitative aspects need to be addressed when

limiting the latency. Additional guidance is provided in AMC 25-19

Section 10, Identification of Candidate CMRs (CCMRs).

Note: For

turbojet thrust reversing systems, the design configurations in paragraphs

8.b(2) and 8.b(3) of AMC 25.933(a)(1) have traditionally been considered

to be acceptable to EASA for compliance with CS 25.1309(b)(4).

(ii) Compliance with CS 25.1309(b)(5)

When a catastrophic failure condition

involves two failures, either one of which is latent for more than one flight,

and cannot reasonably be eliminated, compliance with CS 25.1309(b)(5) is

required. Following the proper application of CS 25.1309(b)(4), the

failure conditions involving multiple significant latent failures are expected

to be sufficiently unlikely such that the dual-failure situations addressed in

CS 25.1309(b)(5) are the only remaining significant latent failures of

concern.

These significant latent failures of

concern should be highlighted to EASA as early as possible. The system safety

assessment should explain why avoidance is not practical, and provide

supporting rationale for the acceptability. Rationale should be based on the

proposed design being state-of-the-art, past experience, sound engineering

judgment, or other arguments, which led to the decision not to implement other

potential means of avoidance (e.g. eliminating the significant latent failure

or adding redundancy).

Two criteria are implemented in CS 25.1309(b)(5): limit latency and limit residual probability.

Limit

latency is intended to limit the time of operating with one evident failure

away from a catastrophic failure condition. This is achieved by requiring that

the sum of the probabilities of the latent failures, which are combined with

each evident failure, does not exceed 1/1 000. Taking one catastrophic

failure condition at a time,

—

in

case an evident failure is combined only once in a dual failure combination of

concern, the probability of the individual latent failure needs to comply with

the 1/1 000 criterion;

—

in

case an evident failure is combined in multiple dual failure combinations of

concern, the combined probabilities of the latent failures need to comply with

the 1/1 000 criterion.

Limit

residual probability is intended to limit the average probability per flight

hour of the failure condition given the presence of a single latent failure.

This is achieved by defining the residual probability to be ‘remote’. Residual

probability is the combined average probability per flight hour of all the

single active failures that result in the catastrophic failure condition

assuming one single latent failure has occurred.

These

requirements are applied in addition to CS 25.1309(b)(1), which requires

that catastrophic failure conditions be shown to be extremely improbable and

do not result from a single failure.

Appendix 5

provides simplified examples explaining how the limit latency and limit

residual probability analysis might be applied.

For

compliance with the 1/1 000 criterion, the probability of the latent

failures of concern should be derived from the probability of the worst-case

flight, i.e. the probability where the evident failure occurs in the last

flight before the scheduled maintenance inspection, while the latent failure

may have occurred in any flight between two consecutive scheduled maintenance

inspections. When dealing with constant failure rates, the probability of the

latent failure should be computed as the product of the maximum time during

which the failure may be present (i.e. exposure time) and its failure rate, if

this probability is less than or equal to 0.1.

c. Compliance with CS 25.1309(c).

CS 25.1309(c) requires that information

concerning unsafe system operating conditions must be provided to the crew to

enable them to take appropriate corrective action in a timely manner, thereby

mitigating the effects to an acceptable level. Any system operating condition

that, if not detected and properly accommodated by flight crew action, would

contribute to or cause a hazardous or catastrophic failure condition should be

considered to be an ‘unsafe system operating condition’. Compliance with this

requirement is usually demonstrated by the analysis identified in paragraph

9.b(1) above, which also includes consideration of crew alerting cues,

corrective action required, and the capability of detecting faults. The

required information may be provided by dedicated indication and/or

annunciation or made apparent to the flight crew by the inherent

aeroplane/systems responses. When flight crew alerting is required, it must be

provided in compliance with CS 25.1322. CS 25.1309(c) also requires

that installed systems and equipment

for use by the flight crew, including flight deck controls and information, be

designed to minimise flight crew errors that could create additional hazards

(in compliance with CS 25.1302).

(1) The required information will depend on

the degree of urgency for recognition and corrective action by the crew. It

should be in the form of:

(i) a warning, if immediate recognition and

corrective or compensatory action by the crew is required;

(ii) a caution if immediate crew awareness is

required and subsequent crew action will be required;

(iii) an advisory, if crew awareness is required

and subsequent crew action may be required;

(iv) a message in the other cases.

CS 25.1322 (and AMC 25.1322) give further requirements (and

guidance) on the characteristics of the information required (visual, aural)

based on those different categories.

(2) When failure monitoring and indication are

provided by a system, its reliability should be compatible with the safety

objectives associated with the system function for which it provides that

indication. For example, if the effects of having a system failure and not

annunciating that system failure are catastrophic, the combination of the

system failure with the failure of its annunciation must be extremely

improbable. The loss of annunciation itself should be considered a failure

condition, and particular attention should be paid to the impact on the

ability of the flight crew to cope with the subject system failure. In

addition, unwanted operation (e.g. nuisance warnings) should be assessed. The

failure monitoring and indication should be reliable, technologically

feasible, and economically practical. Reliable failure monitoring and

indication should utilise current state-of-the-art technology to maximise the

probability of detecting and indicating genuine failures while minimising the

probability of falsely detecting and indicating non-existent failures. Any

indication should be timely, obvious, clear, and unambiguous.

(3) In the case of aeroplane conditions

requiring immediate crew action, a suitable warning indication must be

provided to the crew, if not provided by inherent aeroplane characteristics.

In either case, any warning should be rousing and should occur at a point in a

potentially catastrophic sequence where the aeroplane's capability and the

crew's ability still remain sufficient for effective crew action.

(4) Unless they are accepted as normal

airmanship, procedures for the crew to follow after the occurrence of failure

warning should be described in the approved Aeroplane Flight Manual (AFM) or

AFM revision or supplement.

(5) Even if operation or performance is

unaffected or insignificantly affected at the time of failure, information to

the crew is required if it is considered necessary for the crew to take any

action or observe any precautions. Some examples include reconfiguring a

system, being aware of a reduction in safety margins, changing the flight plan

or regime, or making an unscheduled landing to reduce exposure to a more

severe failure condition that

would result from subsequent failures or operational or environmental

conditions. Information is also required if a failure must be corrected before

a subsequent flight. If operation or performance is unaffected or

insignificantly affected, information and alerting indications may be

inhibited during specific phases of flight where corrective action by the crew

is considered more hazardous than no action.

(6) The use of periodic maintenance or flight

crew checks to detect significant latent failures when they occur is

undesirable and should not be used in lieu of practical and reliable failure

monitoring and indications. When this is not accomplished, refer to paragraph

9.b(6) for guidance.

Paragraph 12

provides further guidance on the use of periodic maintenance or flight crew

checks. Comparison with similar, previously approved systems is sometimes

helpful. However, if a new technical solution allows practical and reliable

failure monitoring and indications, this should be preferred in lieu of

periodic maintenance or flight crew checks.

(7) Particular attention should be given to

the placement of switches or other control devices, relative to one another,

so as to minimise the potential for inadvertent incorrect crew action,

especially during emergencies or periods of high workload. Extra protection,

such as the use of guarded switches, may sometimes be needed.

10. IDENTIFICATION OF FAILURE

CONDITIONS AND CONSIDERATIONS WHEN ASSESSING THEIR EFFECTS.

a. Identification of

Failure Conditions.

Failure

conditions should be identified by considering the potential effects of

failures on the aeroplane and occupants. These should be considered from two

perspectives:

(1) by considering failures of aeroplane-level

functions — failure conditions

identified at this level are not dependent on the way the functions are

implemented and the systems' architecture.

(2) by considering failures of functions at

the system level — these failure

conditions are identified through examination of the way that functions

are implemented and the systems' architectures. It should be noted that a failure condition might result from a

combination of lower-level failure

conditions. This requires that the analysis of complex, highly

integrated systems, in particular, should be conducted in a highly methodical

and structured manner to ensure that all significant failure conditions, that arise from multiple failures and

combinations of lower-level failure

conditions, are properly identified and accounted for. The relevant

combinations of failures and failure

conditions should be determined by the whole safety assessment process

that encompasses the aeroplane and system level functional hazard assessments

and common-cause analyses. The overall effect on the aeroplane of a

combination of individual system failure

conditions occurring as a result of a common or cascade failure, may be

more severe than the individual system effect. For example, failure conditions classified as

minor or major by themselves may have hazardous effects at an aeroplane level,

when considered in combination.

b. Identification of

Failure Conditions Using a Functional Hazard Assessment.

(1) Before a detailed safety assessment is

proceeded with, a functional hazard assessment (FHA) of the aeroplane and

system functions to determine the need for and scope of subsequent analysis

should be prepared. This assessment may be conducted using service experience,

engineering and operational judgement, and/or a top-down deductive qualitative

examination of each function. An FHA is a systematic, comprehensive

examination of aeroplane and system functions to identify potential minor,

major, hazardous, and catastrophic failure

conditions that may arise, not only as a result of malfunctions or

failure to function, but also as a result of normal responses to unusual or

abnormal external factors. It is concerned with the operational

vulnerabilities of systems rather than with a detailed analysis of the actual

implementation.

(2) Each system function should be examined

with respect to the other functions performed by the system, because the loss

or malfunction of all functions performed by the system may result in a more

severe failure condition than the loss of a single function. In addition, each

system function should be examined with respect to functions performed by

other aeroplane systems, because the loss or malfunction of different but

related functions, provided by separate systems may affect the severity of

Failure Conditions postulated for a particular system.

(3) The FHA is an engineering tool, which

should be performed early in the design and updated as necessary. It is used

to define the high-level aeroplane or system safety objectives that must be

considered in the proposed system architectures. It should also be used to

assist in determining the development assurance levels for the systems. Many

systems may need only a simple review of the system design by the applicant to

determine the hazard classification. An FHA requires experienced engineering

judgement and early co-ordination between the applicant and the certification

authority.

(4) Depending on the extent of functions to be

examined and the relationship between functions and systems, different

approaches to FHA may be taken. Where there is a clear correlation between

functions and systems, and where system, and hence function, interrelationships

are relatively simple, it may be feasible to conduct separate FHAs for each

system, providing any interface aspects are properly considered and are easily

understood. Where system and function interrelationships are more complex, a

top-down approach, from an aeroplane-level perspective, should be taken in

planning and conducting FHAs However, with the increasing integrated system

architectures, this traditional top-down approach should be performed in

conjunction with common-cause considerations (e.g. common resources) in order

to properly address the cases where one system contributes to several

aeroplane-level functions.

c. Considerations When

Assessing Failure Condition Effects.

The

requirements of CS 25.1309(b) are intended to ensure an orderly and

thorough evaluation of the effects on safety of foreseeable failures or other

events, such as errors or external circumstances, separately or in

combination, involving one or more system functions. The interactions of these

factors within a system and among relevant systems should be considered.

In assessing

the effects of a failure condition,

factors which might alleviate or intensify the direct effects of the initial failure condition should be

considered. Some of these factors include consequent or related conditions

existing within the aeroplane that may affect the ability of the crew to deal

with direct effects, such as the presence of smoke, acceleration effects,

interruption of communication, interference with cabin pressurisation, etc.

When assessing the consequences of a given failure condition, account should be taken of the failure

information provided, the complexity of the crew action, and the relevant crew

training. The number of overall failure

conditions involving other than instinctive crew actions may influence

the flight crew performance that can be expected. Training recommendations may

need to be identified in some cases.

(1) The severity of failure conditions should be evaluated according to the

following:

(i) Effects on the aeroplane, such as

reductions in safety margins, degradation in performance, loss of capability

to conduct certain flight operations, reduction in environmental protection,

or potential or consequential effects on structural integrity. When the

effects of a failure condition are difficult to assess, the hazard

classification may need to be validated by tests, simulation, or other

appropriate analytical techniques.

(ii) Effects on the crewmembers, such as

increases above their normal workload that would affect their ability to cope

with adverse operational or environmental conditions or subsequent failures.

(iii) Effects on the occupants, i.e., passengers

and crewmembers.

(2) For convenience in conducting design

assessments, failure conditions

may be classified according to the severity of their effects as ‘no safety

effect’, ‘minor’, ‘major’, ‘hazardous’, or ‘catastrophic’. Paragraph 7.a above

provides accepted definitions of these terms.

(i) The classification of failure conditions does not depend on

whether or not a system or function is the subject of a specific requirement

or regulation. Some ʽrequired’ systems, such as transponders, position lights,

and public address systems, may have the potential for only minor failure conditions. Conversely, other

systems which are not ʽrequired’, such as auto-flight systems, may have the

potential for ‘major’, ‘hazardous’, or ‘catastrophic failure conditions’.

(ii) Regardless of the types of assessment

used, the classification of failure

conditions should always be accomplished with consideration of all

relevant factors; e.g., system, crew, performance, operational,

external. It is particularly important to consider factors that would

alleviate or intensify the severity of a failure condition. When flight duration, flight phase, or

diversion time can adversely affect the classification of failure conditions,

they must be considered to be intensifying factors. Other intensifying factors

include conditions that are not related to the failure (such as weather or

adverse operational or environmental conditions), and which reduce the ability

of the flight crew to cope with a failure condition. An example of an

alleviating factor would be the continued performance of identical or

operationally similar functions by other systems not affected by the failure condition. Another example of

an alleviating factor is the ability of the flight crew to recognise the

failure condition and take action to mitigate its effects. Whenever this is

taken into account, particular attention should be paid to the detection means

to ensure that the ability of the flight crew (including physical ability and

timeliness of the response) to detect the failure condition and take the

necessary corrective action(s) is sufficient. Refer to CS 25.1309(c) and paragraph 9.c of this AMC for more detailed guidance on crew

annunciations and crew response evaluation. Combinations of intensifying or

alleviating factors need to be considered only if they are anticipated to

occur together.

11. ASSESSMENT OF FAILURE

CONDITION PROBABILITIES AND ANALYSIS CONSIDERATIONS.

After the failure conditions have been

identified and the severity of the effects of the failure conditions have been assessed, there is a responsibility

to determine how to show compliance with the requirement and obtain the

concurrence of EASA. Design and installation reviews, analyses, flight tests,

ground tests, simulator tests, or other approved means may be used.

a. Assessment of Failure

Condition Probabilities.

(1) The probability that a failure condition would occur may be

assessed as probable, remote, extremely remote, or extremely improbable. These

terms are defined in paragraph 7. Each failure

condition should have a probability that is inversely related to the

severity of its effects as described in paragraph 8.

(2) When a system provides protection from

events (e.g., cargo compartment fire, gusts), its reliability should be

compatible with the safety objectives necessary for the failure condition associated with the

failure of the protection system and the probability of such events. (See

paragraph 11g of this AMC and Appendix 4.)

(3) An assessment to identify and classify failure conditions is necessarily

qualitative. On the other hand, an assessment of the probability of a failure condition may be either

qualitative or quantitative. An analysis may range from a simple report that

interprets test results or compares two similar systems to a detailed analysis

that may or may not include estimated numerical probabilities. The depth and

scope of an analysis depends on the types of functions performed by the

system, the severity of failure

conditions, and whether or not the system is complex.

(4) Experienced engineering and operational

judgement should be applied when determining whether or not a system is

complex. Comparison with similar, previously approved systems is sometimes

helpful. All relevant systems’ attributes should be considered; however, the

complexity of the software and hardware item need not be a dominant factor in

the determination of complexity at the system level.

b. Single Failure

Considerations.

(1) According to the requirements of CS 25.1309(b)(1)(ii), a catastrophic failure

condition must not result from the failure of a single component, part,

or element of a system. Failure containment should be provided by the system

design to limit the propagation of the effects of any single failure to

preclude catastrophic failure

conditions. In addition, there must be no common-cause failure, which

could affect both the single component, part, or element, and its failure

containment provisions. A single failure includes any set of failures, which

cannot be shown to be independent from each other. Common-cause failures

(including common mode failures) and cascading failures should be evaluated as

dependent failures from the point of the root cause or the initiator. Errors

in development, manufacturing, installation, and maintenance can result in

common-cause failures (including common mode failures) and cascading failures.

They should, therefore, be assessed and mitigated in the frame of the

common-cause and cascading failures consideration. Appendix 1 and the Document

referenced in paragraph 3.b(3) describe types of common-cause analyses that

may be conducted, to assure that independence is maintained. Failure

containment techniques available to establish independence may include

partitioning, separation, and isolation.

(2) While single failures must normally be

assumed to occur, there are cases where it is obvious that, from a realistic

and practical viewpoint, any knowledgeable, experienced person would

unequivocally conclude that a failure mode simply would not occur, unless it

is associated with a wholly unrelated failure

condition that would itself be catastrophic. Once identified and

accepted, such cases need not be considered failures in the context of CS 25.1309.

For example, with simply loaded static elements, any failure mode, resulting

from fatigue fracture, can be assumed to be prevented if this element is shown

to meet the damage tolerance requirements of CS 25.571.

c. Common Cause Failure

Considerations.

An analysis

should consider the application of the fail-safe design concept described in

paragraph 6b and give special attention to ensure the effective use of design

and installation techniques that would prevent single failures or other events

from damaging or otherwise adversely affecting more than one redundant system

channel, more than one system performing operationally similar functions, or

any system and an associated safeguard. When considering such common-cause

failures or other events, consequential or cascading effects should be taken

into account. Some examples of such potential common cause failures or other

events would include rapid release of energy from concentrated sources such as

uncontained failures of rotating parts (other than engines and propellers) or

pressure vessels, pressure differentials, non-catastrophic structural

failures, loss of environmental conditioning, disconnection of more than one

subsystem or component by over temperature protection devices, contamination

by fluids, damage from localised fires, loss of power supply or return (e.g.

mechanical damage or deterioration of connections), excessive voltage,

physical or environmental interactions among parts, errors, or events external

to the system or to the aeroplane (see Document referenced in paragraph 3b(3)).

d. Depth

of Analysis.

The

following identifies the depth of analysis expected based on the

classification of a failure condition.

(1) No

Safety Effect Failure Conditions. An FHA, with a design and installation

appraisal, to establish independence from other functions is necessary for the

safety assessment of these failure

conditions. If it is chosen not to do an FHA, the safety effects may be

derived from the design and installation appraisal.

(2) Minor

Failure Conditions. An FHA, with a design and installation appraisal, to

establish independence from other functions is necessary for the safety

assessment of these failure conditions.

Combinations of failure condition

effects, as noted in paragraph 10 above, must also be considered. If it is

chosen not to do an FHA, the safety effects may be derived from the design and

installation appraisal.

(3) Major

Failure Conditions. Major failure conditions must be remote:

(i) If the system is similar in its relevant

attributes to those used in other aeroplanes and the effects of failure would

be the same, then design and installation appraisals (as described in Appendix 1),

and satisfactory service history of the equipment being analysed, or of

similar design, will usually be acceptable for showing compliance.

(ii) For systems that are not complex, where

similarity cannot be used as the basis for compliance, then compliance may be

shown by means of a qualitative assessment that shows that the system-level

major failure conditions, of

the system as installed, are consistent with the FHA and are remote, e.g.

redundant systems.

(iii) For complex systems without redundancy,

compliance may be shown as in paragraph 11.d(3)(ii) of this AMC. To show that

malfunctions are indeed remote in systems of high complexity without

redundancy (for example, a system with a self-monitoring microprocessor), it

is sometimes necessary to conduct a qualitative functional failure modes and

effects analysis (FMEA) supported by failure rate data and fault detection

coverage analysis.

(iv) An analysis of a redundant system is

usually complete if it shows isolation between redundant system channels and

satisfactory reliability for each channel. For complex systems where

functional redundancy is required, a qualitative FMEA and qualitative fault

tree analysis may be necessary to determine that redundancy actually exists

(e.g. no single failure affects all functional channels).

(4) Hazardous

and Catastrophic Failure Conditions.

Hazardous failure conditions must be extremely

remote, and catastrophic failure conditions must be extremely improbable:

(i) Except as specified in paragraph

11.d(4)(ii) below, a detailed safety analysis will be necessary for each

hazardous and catastrophic failure

condition identified by the FHA. The analysis will usually be a

combination of qualitative and quantitative assessment of the design.

(ii) For very simple and conventional

installations, i.e. low complexity and similarity in relevant attributes, it

may be possible to assess a hazardous or catastrophic failure condition as being extremely remote or extremely

improbable, respectively, on the basis of experienced engineering judgement,

using only qualitative analysis. The basis for the assessment will be the

degree of redundancy, the established independence and isolation of the

channels and the reliability record of the technology involved. Satisfactory

service experience on similar systems commonly used in many aeroplanes may be

sufficient when a close similarity is established in respect of both the system

design and operating conditions.

(iii) For complex systems where true similarity

in all relevant attributes, including installation attributes, can be

rigorously established, it may be also possible to assess a hazardous or

catastrophic failure condition

as being extremely remote or extremely improbable, respectively, on the basis

of experienced engineering judgement, using only qualitative analysis. A high

degree of similarity in both design and application is required to be

substantiated.

e. Calculation of

Average Probability per Flight Hour (Quantitative Analysis).

(1) The average probability per flight hour is

the probability of occurrence, normalised by the flight time, of a failure condition during a flight,

which can be seen as an average over all possible flights of the fleet of

aeroplane to be certified. The calculation of the average probability per

flight hour for a failure condition

should consider:

(i) the average flight duration and the

average flight profile for the aeroplane type to be certified,

(ii) all combinations of failures and events

that contribute to the failure

condition,

(iii) the conditional probability if a sequence

of events is necessary to produce the failure

condition,

(iv) the relevant ʽat risk’ time if an event is

only relevant during certain flight phases, and

(v) the exposure time if the failure can

persist for multiple flights.

(2) The details how to calculate the average

probability per flight hour for a failure

condition are given in Appendix 3 of this AMC.

(3) If the probability of a subject failure condition occurring during a

typical flight of mean duration for the aeroplane type divided by the flight’s

mean duration in hours is likely to be significantly different from the

predicted average rate of occurrence of that failure condition during the entire operational life of all

aeroplanes of that type, then a risk model that better reflects the failure condition should be used.

(4) It is recognised that, for various

reasons, component failure rate data are not precise enough to enable accurate

estimates of the probabilities of failure

conditions. This results in some degree of uncertainty, as indicated by

the wide line in Figure 1, and the expression ʽon the order of’ in the

descriptions of the quantitative probability terms that are provided above.

When calculating the estimated probability of each failure condition, this uncertainty should be accounted for in a

way that does not compromise safety.

f. Integrated

Systems.

Interconnections

between systems have been a feature of aeroplane design for many years and CS 25.1309(b)

recognises this in requiring systems to be considered in relation to other

systems. Providing the interfaces between systems are relatively few and

simple, and hence readily understandable, compliance may often be demonstrated

through a series of system safety assessments, each of which deals with a

particular failure condition

(or more likely a group of failure

conditions) associated with a system and, where necessary, takes

account of failures arising at the interface with other systems. This

procedure has been found to be acceptable in many past certification

programmes. However, where the systems and their interfaces become more

complex and extensive, the task of demonstrating compliance may become more

complex. It is therefore essential that the means of compliance be considered

early in the design phase to ensure that the design can be supported by a

viable safety assessment strategy. Aspects of the guidance material covered

elsewhere in this AMC and which should be given particular consideration are as

follows:

(1) planning the proposed means of compliance;

this should include development assurance activities to mitigate the

occurrence of errors in the design,

(2) considering the importance of

architectural design in limiting the impact and propagation of failures,

(3) the potential for common-cause failures

and cascade effects and the possible need to assess combinations of multiple

lower-level (e.g. major) failure

conditions,

(4) the importance of multidisciplinary teams

in identifying and classifying significant failure conditions,

(5) effect of crew and maintenance procedures

in limiting the impact and propagation of failures.

In addition,

rigorous and well-structured design and development procedures play an

essential role in facilitating a methodical safety assessment process and

providing visibility to the means of compliance. Document referenced in

paragraph 3b(2) may be helpful in the certification of highly integrated or

complex aircraft systems.

g. Operational

or Environmental Conditions.

A

probability of one should usually be used for encountering a discrete

condition for which the aeroplane is designed, such as instrument

meteorological conditions or Category III weather operations. However,

Appendix 4 contains allowable probabilities, which may be assigned to various

operational and environmental conditions for use in computing the average

probability per flight hour of failure

conditions without further justification. Single failures, which, in

combination with operational or environmental conditions, lead to catastrophic

failure conditions, are, in general, not acceptable.

Limited