AMC 25.629 Aeroelastic stability requirements

ED

Decision 2020/001/R

1. General.

The general

requirement for demonstrating freedom from aeroelastic instability is

contained in CS 25.629, which also sets forth specific requirements

for the investigation of these aeroelastic phenomena for various aeroplane

configurations and flight conditions. Additionally, there are other conditions

defined by the CS-25 paragraphs listed below to be investigated for

aeroelastic stability to assure safe flight. Many of the conditions contained

in this AMC pertain only to the current amendment of CS-25. Type design

changes to aeroplanes certified to an earlier CS-25 amendment must meet the

certification basis established for the modified aeroplane.

Related

CS-25 paragraphs:

CS 25.251 - Vibration and buffeting

CS 25.305 - Strength and deformation

CS 25.335 - Design airspeeds

CS 25.343 - Design fuel and oil loads

CS 25.571 - Damage-tolerance and fatigue evaluation of

structure

CS 25.629 - Aeroelastic stability requirements

CS 25.631 - Bird strike damage

CS 25.671 - General (Control systems)

CS 25.672 - Stability augmentation and automatic and

power operated systems

CS 25.1309 - Equipment, systems and installations

CS 25.1329 - Flight Guidance system

CS 25.1419 - Ice protection

CS 25.1420 – Supercooled large drop icing conditions

2. Aeroelastic Stability

Envelope

2.1. For nominal conditions without failures,

malfunctions, or adverse conditions, freedom from aeroelastic instability is

required to be shown for all combinations of airspeed and altitude encompassed

by the design dive speed (VD) and design dive Mach number (MD)

versus altitude envelope enlarged at all points by an increase of 15 percent

in equivalent airspeed at both constant Mach number and constant altitude.

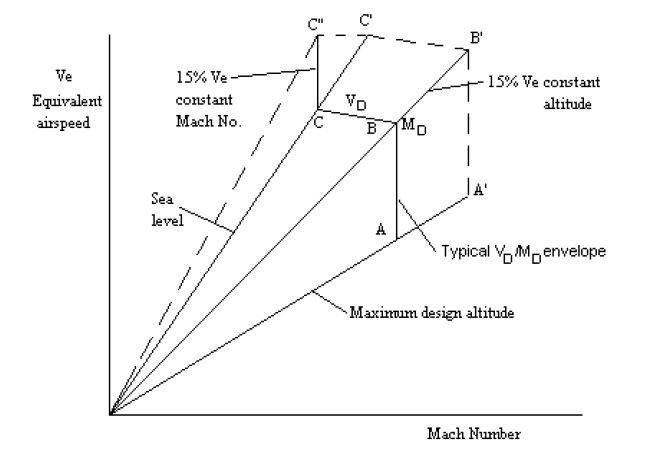

Figure 1A represents a typical design envelope expanded to the required

aeroelastic stability envelope. Note

that some required Mach number and airspeed combinations correspond to

altitudes below standard sea level.

2.2. The aeroelastic stability envelope may be

limited to a maximum Mach number of 1.0 when MD is less than 1.0

and there is no large and rapid reduction in damping as MD is approached.

2.3. Some configurations and conditions that are

required to be investigated by CS 25.629 and other CS-25 regulations

consist of failures, malfunctions or adverse conditions. Aeroelastic stability

investigations of these conditions need to be carried out only within the

design airspeed versus altitude envelope defined by:

(i) the VD/MD envelope

determined by CS 25.335(b); or,

(ii) an altitude-airspeed envelope defined by a

15 percent increase in equivalent airspeed above VC at constant

altitude, from sea level up to the altitude of the intersection of 1.15 VC

with the extension of the constant cruise Mach number line, MC,

then a linear variation in equivalent airspeed to MC + 0.05 at the

altitude of the lowest VC/MC intersection; then at

higher altitudes, up to the maximum flight altitude, the boundary defined by a

0.05 Mach increase in MC at constant altitude.

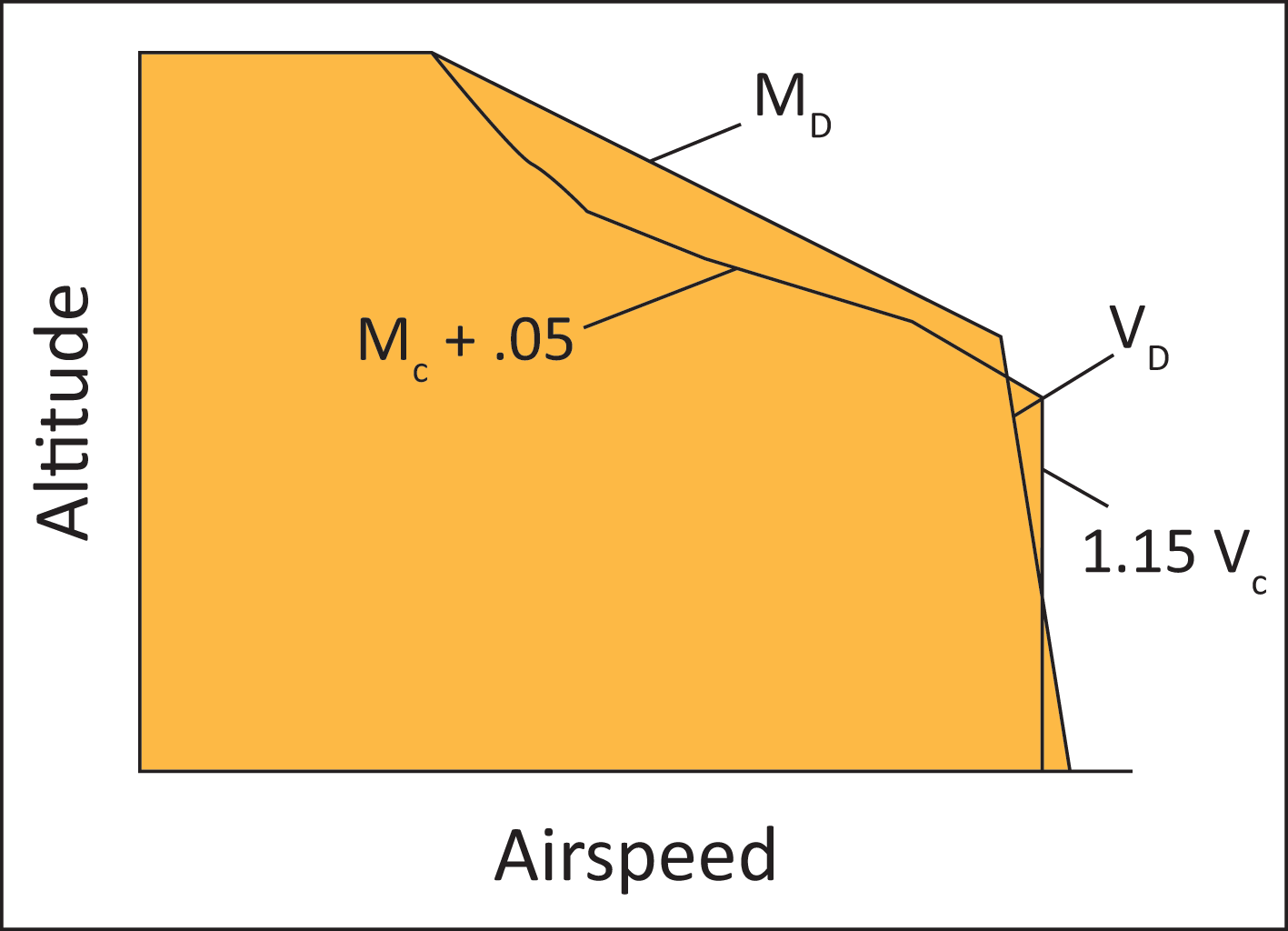

Figure 1B

shows the minimum aeroelastic stability envelope for fail-safe conditions,

which is a composite of the highest speed at each altitude from either the VD

envelope or the constructed altitude-airspeed envelope based on the defined VC

and MC.

Fail-safe

design speeds, other than the ones defined above, may be used for certain

system failure conditions when specifically authorised by other rules or

special conditions prescribed in the certification basis of the aeroplane.

FIGURE 1A.

MINIMUM REQUIRED AEROELASTIC STABILITY MARGIN

FIGURE 1B MINIMUM FAIL-SAFE CLEARANCE ENVELOPE

3. Configurations and

Conditions. The following paragraphs provide a summary of the

configurations and conditions to be investigated in demonstrating compliance

with CS-25. Specific design configurations may warrant additional

considerations not discussed in this AMC.

3.1. Nominal Configurations

and Conditions. Nominal configurations and conditions of the aeroplane

are those that are likely to exist in normal operation. Freedom from

aeroelastic instability should be shown throughout the expanded clearance

envelope described in paragraph 2.1 above for:

3.1.1. The range of fuel and payload combinations,

including zero fuel in the wing, for which certification is requested.

3.1.2. Configurations with ice mass accumulations on

unprotected surfaces for aeroplanes approved for operation in icing

conditions. See paragraph 5.1.4.5 below.

3.1.3. All normal combinations of autopilot, yaw

damper, or other automatic flight control systems.

3.1.4. All possible engine settings and combinations

of settings from idle power to maximum available thrust including the

conditions of one engine stopped and windmilling, in order to address the

influence of gyroscopic loads and thrust on aeroelastic stability.

3.2. Failures, Malfunctions, and

Adverse Conditions. The following conditions should be investigated for

aeroelastic instability within the fail-safe envelope defined in paragraph 2.3.

above.

3.2.1. Any critical fuel loading conditions, not

shown to be extremely improbable, which may result from mismanagement of fuel.

3.2.2. Any single failure in any flutter control

system.

3.2.3. For aeroplanes not approved for operation in

icing conditions, ice accumulation expected as a result of an inadvertent

encounter. For aeroplanes approved for operation in icing conditions, ice

accumulation expected as the result of any single failure in the de-icing

system, or any combination of failures not shown to be extremely improbable.

See paragraph 5.1.4.5 below.

3.2.4. Failure of any single element of the structure

supporting any engine, independently mounted propeller shaft, large auxiliary

power unit, or large externally mounted aerodynamic body (such as an external

fuel tank).

3.2.5. For aeroplanes with engines that have

propellers or large rotating devices capable of significant dynamic forces,

any single failure of the engine structure that would reduce the rigidity of

the rotational axis.

3.2.6. The absence of aerodynamic or gyroscopic

forces resulting from the most adverse combination of feathered propellers or

other rotating devices capable of significant dynamic forces. In addition, the

effect of a single feathered propeller or rotating device should be coupled

with the failures of paragraphs 3.2.4 and 3.2.5 above.

3.2.7. Any single propeller or rotating device

capable of significant dynamic forces rotating at the highest likely

overspeed.

3.2.8. Any damage or failure condition, required or selected

for investigation by CS 25.571. The single structural failures

described in paragraphs 3.2.4 and 3.2.5 above need not be considered in

showing compliance with this paragraph if;

(A) The structural element could not fail due

to discrete source damage resulting from the conditions described in CS

25.571(e) and CS 25.903(d); and

(B) A damage tolerance investigation in

accordance with CS 25.571(b) shows that the maximum extent of damage

assumed for the purpose of residual strength evaluation does not involve

complete failure of the structural element.

3.2.9. The following flight control system failure

combinations where aeroelastic stability relies on flight control system

stiffness and/or damping:

(i) any dual hydraulic system failure;

(ii) any dual electrical system failure; and

(iii) any single failure in combination with any

probable hydraulic system or electrical system failure.

3.2.10. Any damage, failure or malfunction,

considered under CS 25.631, CS 25.671, CS 25.672, and CS 25.1309. This includes the condition of two or more

engines stopped or wind milling for the design range of fuel and payload

combinations, including zero fuel.

3.2.11. Any

other combination of failures, malfunctions, or adverse conditions not shown

to be extremely improbable.

4. Detail Design

Requirements.

4.1. Main surfaces, such as wings and

stabilisers, should be designed to meet the aeroelastic stability criteria for

nominal conditions and should be investigated for meeting fail-safe criteria

by considering stiffness changes due to discrete damage or by reasonable

parametric variations of design values.

4.2. Control surfaces, including tabs, should be

investigated for nominal conditions and for failure modes that include single

structural failures (such as actuator disconnects, hinge failures, or, in the

case of aerodynamic balance panels, failed seals), single and dual hydraulic

system failures and any other combination of failures not shown to be

extremely improbable. Where other structural components contribute to the

aeroelastic stability of the system, failures of those components should be

considered for possible adverse effects.

4.3. Where aeroelastic stability relies on flight

control system stiffness and/or damping, additional conditions should be

considered. The actuation system should continuously provide, at least, the

minimum stiffness or damping required for showing aeroelastic stability

without regard to probability of occurrence for:

(i) more than one engine stopped or wind

milling,

(ii) any discrete single failure resulting in a

change of the structural modes of vibration (for example; a disconnection or

failure of a mechanical element, or a structural failure of a hydraulic

element, such as a hydraulic line, an actuator, a spool housing or a valve);

(iii) any damage or failure conditions

considered under CS 25.571, CS 25.631 and CS 25.671.

The

actuation system minimum requirements should also be continuously met after

any combination of failures not shown to be extremely improbable (occurrence

less than 10-9 per

flight hour). However, some combinations of failures, such as dual electrical

system or dual hydraulic system failures, or any single failure in combination

with any probable electrical or hydraulic system failure, are normally not

demonstrated as being extremely improbable The reliability assessment should

be part of the substantiation documentation. In practice, meeting the above

conditions may involve design concepts such as the use of check valves and

accumulators, computerised pre-flight system checks and shortened inspection

intervals to protect against undetected failures.

4.4 Consideration of free play may be

incorporated as a variation in stiffness to assure adequate limits are

established for wear of components such as control surface actuators, hinge

bearings, and engine mounts in order to maintain aeroelastic stability

margins.

4.5. If balance weights are used on control

surfaces, their effectiveness and strength, including that of their support

structure, should be substantiated.

4.6 The automatic flight control system should

not interact with the airframe to produce an aeroelastic instability. When analyses indicate possible adverse

coupling, tests should be performed to determine the dynamic characteristics

of actuation systems such as servo-boost, fully powered servo-control systems,

closed-loop aeroplane flight control systems, stability augmentation systems,

and other related powered-control systems.

5. Compliance. Demonstration of compliance

with aeroelastic stability requirements for an aircraft configuration may be

shown by analyses, tests, or some combination thereof. In most instances, analyses are required to

determine aeroelastic stability margins for normal operations, as well as for

possible failure conditions. Wind tunnel flutter model tests, where

applicable, may be used to supplement flutter analyses. Ground testing may be

used to collect stiffness or modal data for the aircraft or components. Flight

testing may be used to demonstrate compliance of the aircraft design

throughout the design speed envelope.

5.1. Analytical Investigations. Analyses should

normally be used to investigate the aeroelastic stability of the aircraft

throughout its design flight envelope and as expanded by the required speed

margins. Analyses are used to evaluate

aeroelastic stability sensitive parameters such as aerodynamic coefficients,

stiffness and mass distributions, control surface balance requirements, fuel

management schedules, engine/store locations, and control system characteristics.

The sensitivity of most critical parameters may be determined analytically by

varying the parameters from nominal. These investigations are an effective way

to account for the operating conditions and possible failure modes which may

have an effect on aeroelastic stability margins, and to account for

uncertainties in the values of parameters and expected variations due to

in-service wear or failure conditions.

5.1.1. Analytical Modelling. The following paragraphs

discuss acceptable, but not the only, methods and forms of modelling aircraft

configurations and/or components for purposes of aeroelastic stability

analysis. The types of investigations generally encountered in the course of

aircraft aeroelastic stability substantiation are also discussed. The basic

elements to be modelled in aeroelastic stability analyses are the elastic,

inertial, and aerodynamic characteristics of the system. The degree of

complexity required in the modelling, and the degree to which other

characteristics need to be included in the modelling, depend upon the system

complexity.

5.1.1.1.

Structural Modelling. Most forms of structural modelling can be classified

into two main categories: (1) modelling using a lumped mass beam, and (2)

finite element modelling. Regardless of the approach taken for structural

modelling, a minimum acceptable level of sophistication, consistent with

configuration complexity, is necessary to satisfactorily represent the

critical modes of deformation of the primary structure and control

surfaces. The model should reflect the

support structure for the attachment of control surface actuators, flutter

dampers, and any other elements for which stiffness is important in prevention

of aeroelastic instability. Wing-pylon mounted engines are often significant

to aeroelastic stability and warrant particular attention in the modelling of

the pylon, and pylon-engine and pylon-wing interfaces. The model should

include the effects of cut-outs, doors, and other structural features which

may tend to affect the resulting structural effectiveness. Reduced stiffness

should be considered in the modelling of aircraft structural components which

may exhibit some change in stiffness under limit design flight conditions.

Structural models include mass distributions as well as representations of

stiffness and possibly damping characteristics. Results from the models should

be compared to test data, such as that obtained from ground vibration tests,

in order to determine the accuracy of the model and its applicability to the

aeroelastic stability investigation.

5.1.1.2.

Aerodynamic Modelling.

(a) Aerodynamic modelling for aeroelastic

stability requires the use of unsteady, two-dimensional strip or

three-dimensional panel theory methods for incompressible or compressible

flow. The choice of the appropriate technique depends on the complexity of the

dynamic structural motion of the surfaces under investigation and the flight speed

envelope of the aircraft. Aerodynamic modelling should be supported by tests

or previous experience with applications to similar configurations.

(b) Main and control surface aerodynamic data

are commonly adjusted by weighting factors in the aeroelastic stability

solutions. The weighting factors for steady flow (k=0) are usually obtained by

comparing wind tunnel test results with theoretical data. Special attention should be given to control

surface aerodynamics because viscous and other effects may require more

extensive adjustments to theoretical coefficients. Main surface aerodynamic

loading due to control surface deflection should be considered.

5.1.2. Types of Analyses.

5.1.2.1.

Oscillatory (flutter) and non-oscillatory (divergence and control reversal)

aeroelastic instabilities should be analysed to show compliance with CS 25.629.

5.1.2.2.

The flutter analysis methods most extensively used involve modal analysis with

unsteady aerodynamic forces derived from various two- and three-dimensional

theories. These methods are generally for linear systems. Analyses involving

control system characteristics should include equations describing system

control laws in addition to the equations describing the structural modes.

5.1.2.3.

Aeroplane lifting surface divergence analyses should include all appropriate

rigid body mode degrees-of-freedom since divergence may occur for a structural

mode or the short period mode.

5.1.2.4.

Loss of control effectiveness (control reversal) due to the effects of elastic

deformations should be investigated. Analyses should include the inertial,

elastic, and aerodynamic forces resulting from a control surface deflection.

5.1.3 Damping Requirements.

5.1.3.1.

There is no intent in this AMC to define a flight test level of acceptable

minimum damping.

5.1.3.2.

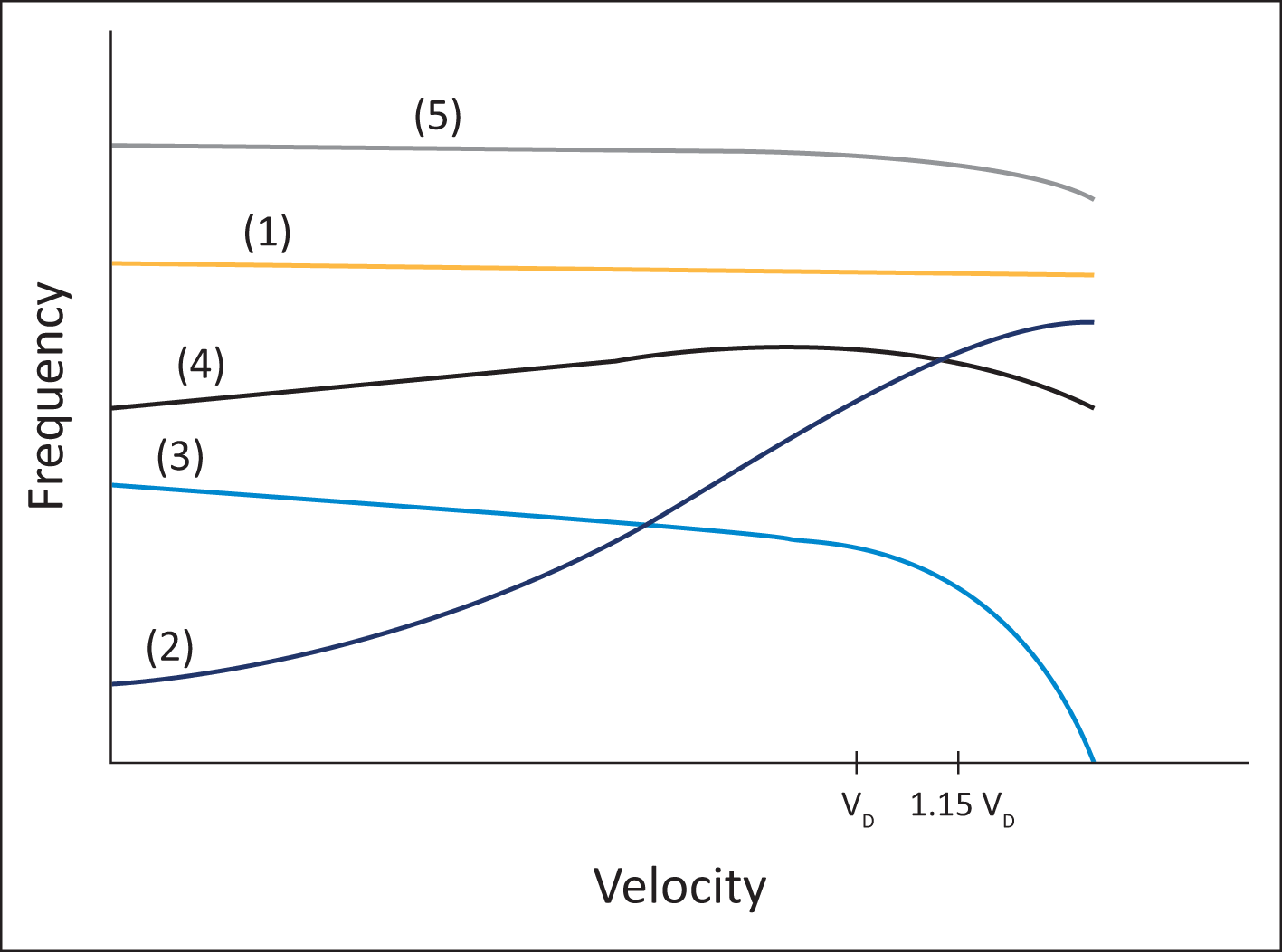

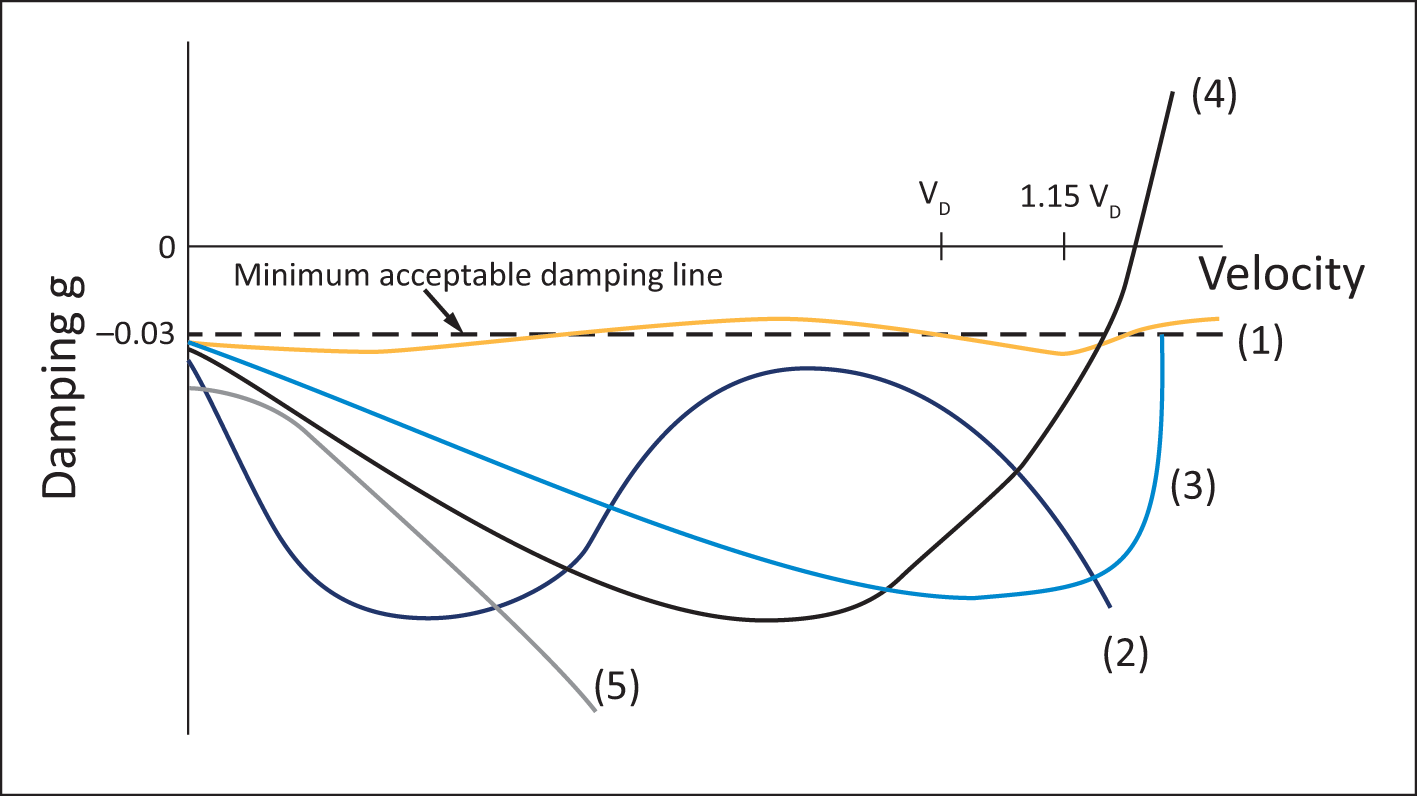

Flutter analyses results are usually presented graphically in the form of

frequency versus velocity (V-f, Figure 2) and damping versus velocity (V-g,

Figures 3 and 4) curves for each root of the flutter solution.

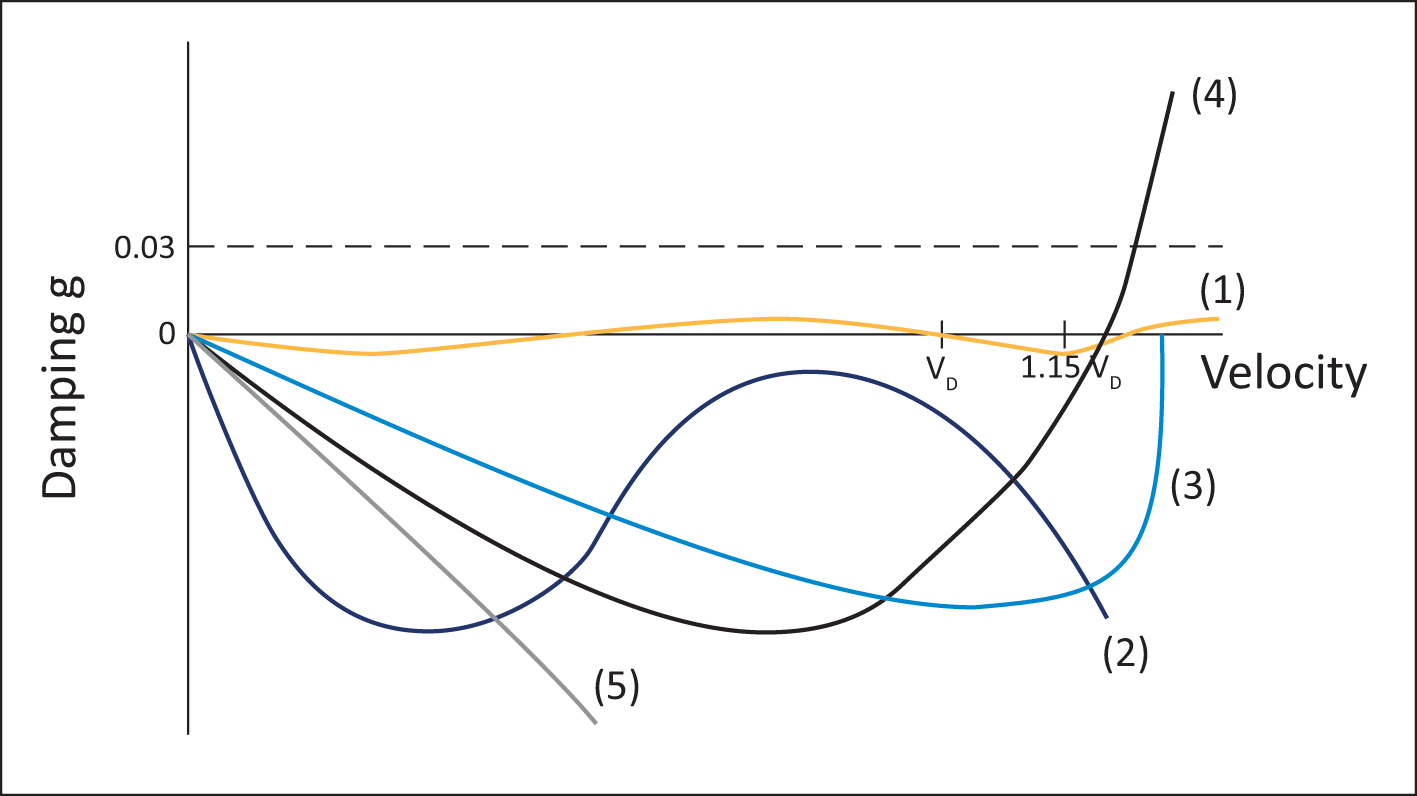

5.1.3.3.

Figure 3 details one common method for showing compliance with the requirement

for a proper margin of damping. It is

based on the assumption that the structural damping available is 0.03 (1.5%

critical viscous damping) and is the same for all modes as depicted by the V-g

curves shown in Figure 3. No

significant mode, such as curves (2) or (4), should cross the g=0 line below VD

or the g=0.03 line below 1.15 VD. An exception may be a mode

exhibiting damping characteristics similar to curve (1) in Figure 3, which is

not critical for flutter. A divergence mode, as illustrated by curve (3) where

the frequency approaches zero, should have a divergence velocity not less than

1.15 VD.

5.1.3.4.

Figure 4 shows another common method of presenting the flutter analysis

results and defining the structural damping requirements. An appropriate amount of structural damping

for each mode is entered into the analysis prior to the flutter solution. The amount of structural damping used should

be supported by measurements taken during full scale tests. This results in

modes offset from the g=0 line at zero airspeed and, in some cases, flutter

solutions different from those obtained with no structural damping. The

similarity in the curves of Figures 3 and 4 are only for simplifying this

example. The minimum acceptable damping line applied to the analytical results

as shown in Figure 4 corresponds to 0.03 or the modal damping available at

zero airspeed for the particular mode of interest, whichever is less, but in

no case less than 0.02. No significant mode should cross this line below VD

or the g=0 line below 1.15 VD.

5.1.3.5.

For analysis of failures, malfunctions or adverse conditions being

investigated, the minimum acceptable damping level obtained analytically would

be determined by use of either method above, but with a substitution of VC

for VD and the fail-safe envelope speed at the analysis altitude as

determined by paragraph 2.3 above.

FIGURE 2: FREQUENCY VERSUS VELOCITY

FIGURE 3: DAMPING VERSUS VELOCITY -

Method 1

FIGURE 4: DAMPING VERSUS VELOCITY -

Method 2

5.1.4. Analysis Considerations. Airframe aeroelastic

stability analyses may be used to verify the design with respect to the structural

stiffness, mass, fuel (including in-flight fuel management), automatic flight

control system characteristics, and altitude and Mach number variations within

the design flight envelope. The complete aeroplane should be considered as

composed of lifting surfaces and bodies, including all primary control

surfaces which can interact with the lifting surfaces to affect flutter

stability. Control surface flutter can occur in any speed regime and has

historically been the most common form of flutter. Lifting surface flutter is

more likely to occur at high dynamic pressure and at high subsonic and

transonic Mach numbers. Analyses are necessary to establish the mass balance

and/or stiffness and redundancy requirements for the control surfaces and

supporting structure and to determine the basic surface flutter trends. The

analyses may be used to determine the sensitivity of the nominal aircraft

design to aerodynamic, mass, and stiffness variations. Sources of stiffness variation may include

the effects of skin buckling at limit load factor, air entrapment in hydraulic

actuators, expected levels of in-service free play, and control system

components which may include elements with non-linear stiffness. Mass

variations include the effects of fuel density and distribution, control

surface repairs and painting, and water and ice accumulation.

5.1.4.1.

Control Surfaces. Control surface aeroelastic stability analyses should

include control surface rotation, tab rotation (if applicable), significant

modes of the aeroplane, control surface torsional degrees-of-freedom, and

control surface bending (if applicable). Analyses of aeroplanes with tabs

should include tab rotation that is both independent and related to the parent

control surface. Control surface rotation frequencies should be varied about

nominal values as appropriate for the condition. The control surfaces should

be analysed as completely free in rotation unless it can be shown that this

condition is extremely improbable. All conditions between stick-free and stick-fixed

should be investigated. Free play effects should be incorporated to account

for any influence of in-service wear on flutter margins. The aerodynamic

coefficients of the control surface and tab used in the aeroelastic stability

analysis should be adjusted to match experimental values at zero frequency. Once

the analysis has been conducted with the nominal, experimentally adjusted

values of hinge moment coefficients, the analysis should be conducted with

parametric variations of these coefficients and other parameters subject to

variability. If aeroelastic stability margins are found to be sensitive to

these parameters, then additional verification in the form of model or flight

tests may be required.

5.1.4.2.

Mass Balance.

(a) The magnitude and spanwise location of

control surface balance weights may be evaluated by analysis and/or wind

tunnel flutter model tests. If the control surface torsional degrees of

freedom are not included in the analysis, then adequate separation needs to be

maintained between the frequency of the control surface first torsion mode and

the flutter mode.

(b) Control surface unbalance tolerances

should be specified to provide for repair and painting. The accumulation of

water, ice, and/or dirt in or near the trailing edge of a control surface

should be avoided. Free play between the balance weight, the support arm, and

the control surface should not be allowed. Control surface mass properties

(weight and static unbalance) should be confirmed by measurement before ground

vibration testing.

(c) The balance weights and their supporting

structure should be substantiated for the extreme load factors expected

throughout the design flight envelope. If the absence of a rational

investigation, the following limit accelerations, applied through the balance

weight centre of gravity should be used.

—

100g

normal to the plane of the surface

—

30g

parallel to the hinge line

—

30g

in the plane of the surface and perpendicular to the hinge line

5.1.4.3.

Passive Flutter Dampers. Control surface passive flutter dampers may be used

to prevent flutter in the event of failure of some element of the control

surface actuation system or to prevent control surface buzz. Flutter analyses

and/or flutter model wind tunnel tests may be used to verify adequate damping.

Damper support structure flexibility should be included in the determination

of adequacy of damping at the flutter frequencies. Any single damper failure

should be considered. Combinations of multiple damper failures should be

examined when not shown to be extremely improbable. The combined free play of the damper and

supporting elements between the control surface and fixed surfaces should be

considered. Provisions for in-service checks of damper integrity should be

considered. Refer to paragraph 4.3 above for conditions to consider where a

control surface actuator is switched to the role of an active or passive

damping element of the flight control system.

5.1.4.4. Intersecting

Lifting Surfaces. Intersecting lifting surface aeroelastic stability

characteristics are more difficult to predict accurately than the

characteristics of planar surfaces such as wings. This is due to difficulties

both in correctly predicting vibration modal characteristics and in assessing

those aerodynamic effects which may be of second order importance on planar

surfaces, but are significant for intersecting surfaces. Proper representation

of modal deflections and unsteady aerodynamic coupling terms between surfaces

is essential in assessing the aeroelastic stability characteristics. The

in-plane forces and motions of one or the other of the intersecting surfaces

may have a strong effect on aeroelastic stability; therefore, the analysis

should include the effects of steady flight forces and elastic deformations on

the in-plane effects.

5.1.4.5. Ice

Accumulation. Aeroelastic stability analyses should use the mass distributions

derived from ice accumulations up to and including those that can accrete in

the applicable icing conditions in Appendices C and O to CS-25. This includes

any accretions that could develop on control surfaces. The analyses need not

consider the aerodynamic effects of ice shapes. For aeroplanes approved for

operation in icing conditions, all of the CS-25 Appendix C icing conditions

and the Appendix O icing conditions for which certification is sought are

applicable. For aeroplanes not approved for operation in icing conditions, all

of the Appendix C and O icing conditions are applicable since the inadvertent

encounter discussed in paragraph 3.2.3 of this AMC can occur in any icing

condition. For all aeroplanes, the ice accumulation determination should take

into account the ability to detect the ice and, if appropriate, the time

required to leave the icing condition.

For showing

compliance with the CS-25 specifications relative to SLD icing conditions

represented by Appendix O, the applicant may use a comparative analysis. AMC

25.1420(f) provides guidance for comparative analysis.

5.1.4.6.

Whirl Flutter.

(a) The evaluation of the aeroelastic

stability should include investigations of any significant elastic, inertial,

and aerodynamic forces, including those associated with rotations and

displacements in the plane of any turbofan or propeller, including propeller

or fan blade aerodynamics, powerplant flexibilities, powerplant mounting

characteristics, and gyroscopic coupling.

(b) Failure conditions are usually significant

for whirl instabilities. Engine mount,

engine gear box support, or shaft failures which result in a node line shift

for propeller hub pitching or yawing motion are especially significant.

(c) A wind tunnel test with a component

flutter model, representing the engine/propeller system and its support system

along with correlative vibration and flutter analyses of the flutter model,

may be used to demonstrate adequate stability of the nominal design and failed

conditions.

5.1.4.7.

Automatic Control Systems. Aeroelastic stability analyses of the basic

configuration should include simulation of any control system for which

interaction may exist between the sensing elements and the structural modes. Where

structural/control system feedback is a potential problem the effects of

servo-actuator characteristics and the effects of local deformation of the

servo mount on the feedback sensor output should be included in the analysis. The

effect of control system failures on the aeroplane aeroelastic stability

characteristics should be investigated.

Failures which significantly affect the system gain and/or phase and

are not shown to be extremely improbable should be analysed.

5.2. Testing. The aeroelastic stability

certification test programme may consist of ground tests, flutter model tests,

and flight flutter tests. Ground tests may be used for assessment of component

stiffness and for determining the vibration modal characteristics of aircraft

components and the complete airframe.

Flutter model testing may be used to establish flutter trends and

validate aeroelastic stability boundaries in areas where unsteady aerodynamic

calculations require confirmation. Full

scale flight flutter testing provides final verification of aeroelastic

stability. The results of any of these

tests may be used to provide substantiation data, to verify and improve

analytical modelling procedures and data, and to identify potential or

previously undefined problem areas.

5.2.1. Structural Component Tests. Stiffness tests or

ground vibration tests of structural components are desirable to confirm

analytically predicted characteristics and are necessary where stiffness

calculations cannot accurately predict these characteristics. Components

should be mounted so that the mounting characteristics are well defined or

readily measurable.

5.2.2. Control System Component Tests. When reliance

is placed on stiffness or damping to prevent aeroelastic instability, the

following control system tests should be conducted. If the tests are performed

off the aeroplane the test fixtures should reflect local attachment

flexibility.

(i) Actuators for primary flight control

surfaces and flutter dampers should be tested with their supporting structure.

These tests are to determine the actuator/support structure stiffness for

nominal design and failure conditions considered in the fail-safe analysis.

(ii) Flutter damper tests should be conducted

to verify the impedance of damper and support structure. Satisfactory

installed damper effectiveness at the potential flutter frequencies should,

however, be assured. The results of these tests can be used to determine a

suitable, in-service maintenance schedule and replacement life of the

damper. The effects of allowable

in-service free play should be measured.

5.2.3. Ground vibration Tests.

5.2.3.1.

Ground vibration tests (GVT) or modal response tests are normally conducted on

the complete conforming aeroplane. A GVT may be used to check the mathematical

structural model. Alternatively, the use of measured modal data alone in

aeroelastic stability analyses, instead of analytical modal data modified to

match test data, may be acceptable provided the accuracy and completeness of

the measured modal data is established.

Whenever structural modifications or inertia changes are made to a

previously certified design or a GVT validated model of the basic aeroplane, a

GVT may not be necessary if these changes are shown not to affect the

aeroelastic stability characteristics.

5.2.3.2.

The aeroplane is best supported such that the suspended aeroplane rigid body

modes are effectively uncoupled from the elastic modes of the aeroplane.

Alternatively, a suspension method may be used that couples with the elastic

aeroplane provided that the suspension can be analytically de-coupled from the

aeroplane structure in the vibration analysis.

The former suspension criterion is preferred for all ground vibration

tests and is necessary in the absence of vibration analysis.

5.2.3.3.

The excitation method needs to have sufficient force output and frequency

range to adequately excite all significant resonant modes. The effective mass

and stiffness of the exciter and attachment hardware should not distort modal

response. More than one exciter or exciter location may be necessary to insure

that all significant modes are identified. Multiple exciter input may be

necessary on structures with significant internal damping to avoid low

response levels and phase shifts at points on the structure distant from the

point of excitation. Excitation may be sinusoidal, random, pseudo-random,

transient, or other short duration, non stationary means. For small surfaces the effect of test sensor

mass on response frequency should be taken into consideration when analysing

the test results.

5.2.3.4.

The minimum modal response measurement should consist of acceleration (or

velocity) measurements and relative phasing at a sufficient number of points

on the aeroplane structure to accurately describe the response or mode shapes

of all significant structural modes. In

addition, the structural damping of each mode should be determined.

5.2.4. Flutter Model Tests.

5.2.4.1.

Dynamically similar flutter models may be tested in the wind tunnel to augment

the flutter analysis. Flutter model testing can substantiate the flutter

margins directly or indirectly by validating analysis data or methods. Some

aspects of flutter analysis may require more extensive validation than others,

for example control surface aerodynamics, T-tails and other configurations

with aerodynamic interaction and compressibility effects. Flutter testing may

additionally be useful to test configurations that are impractical to verify

in flight test., such as fail-safe conditions or extensive store

configurations. In any such testing, the mounting of the model and the

associated analysis should be appropriate and consistent with the study being

performed.

5.2.4.2.

Direct substantiation of the flutter margin (clearance testing) implies a high

degree of dynamic similitude. Such a test may be used to augment an analysis

and show a configuration flutter free throughout the expanded design envelope.

All the physical parameters which have been determined to be significant for

flutter response should be appropriately scaled. These will include elastic and inertia

properties, geometric properties and dynamic pressure. If transonic effects

are important, the Mach number should be maintained.

5.2.4.3.

Validation of analysis methods is another appropriate use of wind tunnel

flutter testing. When the validity of a method is uncertain, correlation of

wind tunnel flutter testing results with a corresponding analysis may increase

confidence in the use of the analytical tool for certification analysis. A

methods validation test should simulate conditions, scaling and geometry

appropriate for the intended use of the analytical method.

5.2.4.4.

Trend studies are an important use of wind tunnel flutter testing. Parametric

studies can be used to establish trends for control system balance and

stiffness, fuel and payload variations, structural compliances and

configuration variations. The set of physical parameters requiring similitude

may not be as extensive to study parametric trends as is required for

clearance testing. For example, an

exact match of the Mach number may not be required to track the effects of

payload variations on a transonic aeroplane.

5.2.5. Flight Flutter Tests.

5.2.5.1.

Full scale flight flutter testing of an aeroplane configuration to VDF/MDF

is a necessary part of the flutter substantiation. An exception may be made when aerodynamic,

mass, or stiffness changes to a certified aeroplane are minor, and analysis or

ground tests show a negligible effect on flutter or vibration characteristics.

If a failure, malfunction, or adverse condition is simulated during a flight

test, the maximum speed investigated need not exceed VFC/MFC

if it is shown, by correlation of the flight test data with other test data or analyses, that the

requirements of CS 25.629(b)(2) are met.

5.2.5.2.

Aeroplane configurations and control system configurations should be selected

for flight test based on analyses and, when available, model test results.

Sufficient test conditions should be performed to demonstrate aeroelastic

stability throughout the entire flight envelope for the selected

configurations.

5.2.5.3.

Flight flutter testing requires excitation sufficient to excite the modes

shown by analysis to be the most likely to couple for flutter. Excitation

methods may include control surface motions or internal moving mass or

external aerodynamic exciters or flight turbulence. The method of excitation should

be appropriate for the modal response frequency being investigated. The effect of the excitation system itself

on the aeroplane flutter characteristics should be determined prior to flight

testing.

5.2.5.4.

Measurement of the response at selected locations on the structure should be

made in order to determine the response amplitude, damping and frequency in

the critical modes at each test airspeed. It is desirable to monitor the

response amplitude, frequency and damping change as VDF/MDF

is approached. In demonstrating that there is no large and rapid damping

reduction as VDF/MDF is approached, an endeavour should

be made to identify a clear trend of damping versus speed. If this is not

possible, then sufficient test points should be undertaken to achieve a

satisfactory level of confidence that there is no evidence of an adverse

trend.

5.2.5.5.

An evaluation of phenomena not presently amenable to analyses, such as shock

effects, buffet response levels, vibration levels, and control surface buzz,

should also be made during flight testing.

[Amdt 25/1]

[Amdt

25/6]

[Amdt

25/16]

[Amdt

25/18]

[Amdt

25/24]