AMC 25.1709 System safety; EWIS

ED

Decision 2008/006/R

25.1709

requires applicants to perform a system safety assessment of the EWIS. The

analysis required for compliance with CS 25.1709 is based on a qualitative approach

to assessing EWIS safety as opposed to numerical, probability-based

quantitative analysis. The safety assessment must consider the effects that

both physical and functional failures of EWIS would have on aeroplane safety.

That safety assessment must show that each EWIS failure considered hazardous

is extremely remote. It must show that each EWIS failure considered to be

catastrophic is extremely improbable and will not result from a single

failure.

1 Objective.

The

objective of CS 25.1709 is to use the concepts of CS 25.1309

to provide a thorough and structured analysis of aircraft wiring and its

associated components. As in CS 25.1309, the fail-safe design concept applies.

Any single failure condition, such as an arc fault, should be assumed to occur

regardless of probability.

2 Inadequacies of CS 25.1309

in relation to EWIS safety assessments.

CS 25.1309

requires the applicant to perform system safety assessments. But current CS

25.1309 practice has not led to the type of analysis that fully ensures all

EWIS failure conditions affecting aeroplane level safety are considered. This

is because wiring for non-required systems is sometimes ignored. Even for

systems covered by CS 25.1309(b), the safety analysis requirements have not

always been applied to the associated wire. When they are, there is evidence

of inadequate and inconsistent application. Traditional thinking about

non-required systems, such as IFE, has been that, since they are not required,

and the function they provide is not necessary for the safety of the

aeroplane, their failure could not affect the safety of the aeroplane. This is

not a valid assumption. Failure of an electrical wire, regardless of the

system it is associated with, can cause serious physical and functional damage

to the aeroplane, resulting in hazardous or even catastrophic failure

conditions. An example of this is arcing from a shorted wire cutting through

and damaging flight control cables. There are more failure modes than have

been addressed with traditional analyses. Some further examples are arcing

events that occur without tripping circuit breakers, resulting in complete

wire bundle failures and fire; or wire bundle failures that lead to structural

damage

3 Integrated nature of EWIS.

The

integrated nature of wiring and the potential severity of failures demand a

more structured safety analysis approach than that traditionally used under CS 25.1309. CS 25.1309 system safety

assessments typically evaluate effects of wire failures on system functions.

But they have not considered physical wire failure as a cause of the failure

of other wires within the EWIS. Traditional assessments look at external

factors like rotor burst, lightning, and hydraulic line rupture, but not at

internal factors, like a single wire chafing or arcing event, as the cause of

the failure of functions supported by the EWIS. Compliance with CS 25.1709

requires addressing those failure modes at the aeroplane level. This means

that EWIS failures need to be analyzed to determine what effect they could

have on the safe operation of the aeroplane.

4 Compliance summary.

As specified

above, the analysis required for compliance with CS 25.1709

is based on a qualitative approach to assessing EWIS safety as opposed to

numerical, probability-based quantitative analysis. The intent is not to

examine each individual wire and its relation to other wires. Rather, it is to

ensure that there are no combinations of failures that could lead to a

hazardous condition. However, in case the “top down” analysis process

described in this AMC determines that a failure in a given bundle may lead to

a catastrophic failure condition, the mitigation process may lead to

performing a complete analysis of each wire in the relevant bundle.

5 Qualitative probability terms.

When using

qualitative analyses to determine compliance with CS 25.1709,

the following descriptions of the probability terms have become commonly

accepted as aids to engineering judgment:

a. Extremely remote failure conditions.

These are

failure conditions that are not anticipated to occur to an individual

aeroplane during its total life but which may occur a few times when

considering the total operational life of all aeroplanes of the type.

b. Extremely improbable failure conditions.

These are

failure conditions so unlikely that they are not anticipated to occur during

the entire operational life of all aeroplanes of one type.

6 Relationship to CS 25 system safety

assessments.

The analysis

described may be accomplished in conjunction with the required aircraft system

safety assessments of CS 25.1309, 25.671, etc.

7 Classification of failure terms.

The

classification of failure conditions is specified in AMC 25.1309.

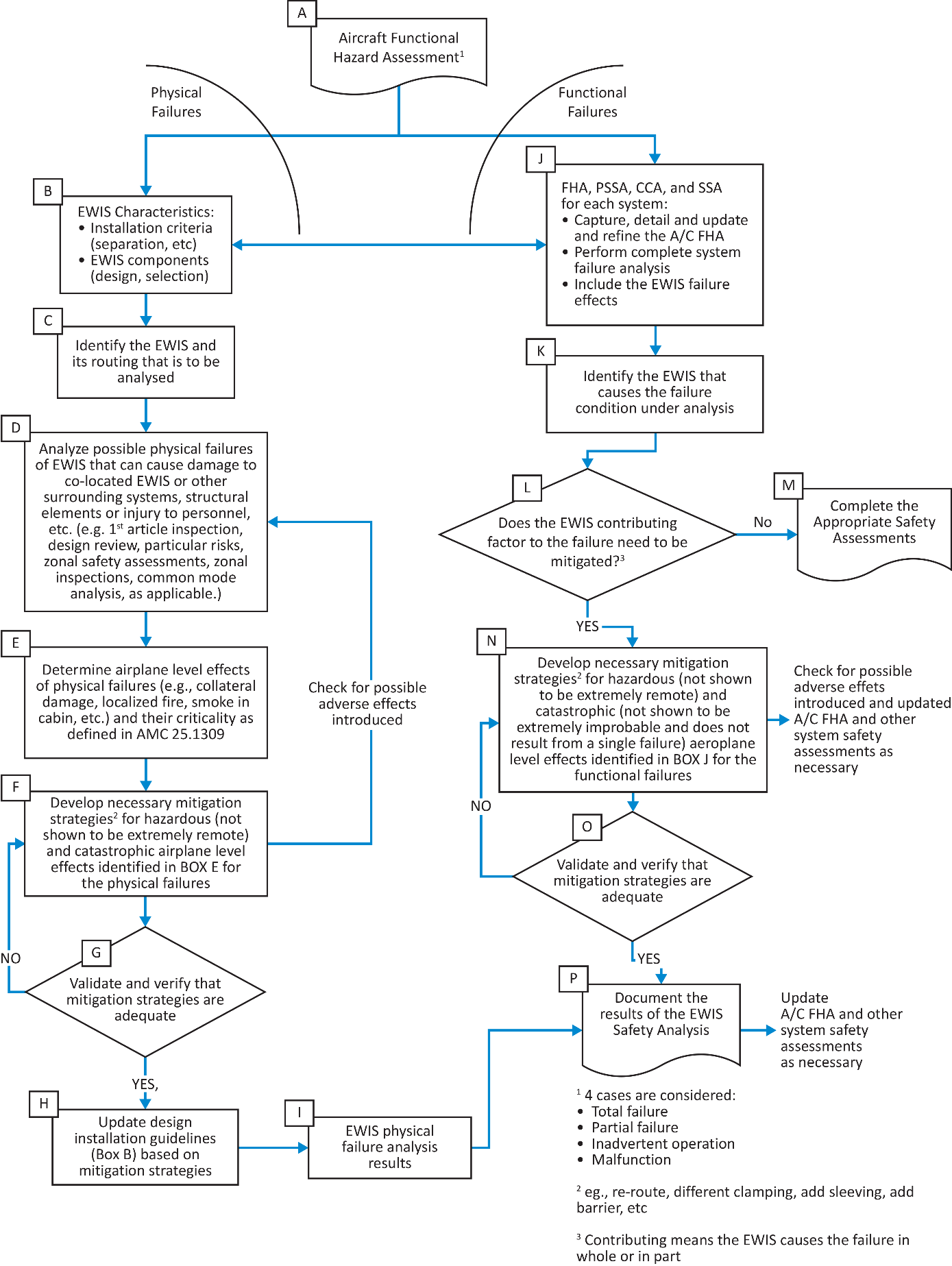

8 Flowcharts depicting the analysis

process.

Flowcharts 1

and 2 outline one method of complying with the requirements of CS 25.1709.

The processes in both Flowcharts 1 and 2 identify two aspects of the analysis:

physical failures and functional failures. The processes described in both

flowcharts begins by using the aircraft level functional hazard analysis

developed for demonstrating compliance with CS 25.1309 to identify catastrophic and

hazardous failure events. A step-by-step explanation of the analysis depicted

in the flowcharts is given in paragraphs 11 (for flowchart 1) and 12 (for

Flowchart 2).

a. Flowchart 1.

This

flowchart applies to applicants for pre-TC work and for amended TCs, and STCs

when the applicant has all data necessary to perform the analysis. If

Flowchart 1 is used for post-TC modifications the available data must include

identification of the systems in the EWIS under consideration for modification

and the system functions associated with that EWIS.

b. Flowchart 2.

This

flowchart applies to applicants for post-TC modifications when the applicant

cannot identify the systems or systems functions contained in EWIS under

consideration for modification.

9 Definitions applicable to CS 25.1709.

For this

discussion the following definitions apply:

a. Validation. Determination that requirements

for a product are sufficiently correct and complete.

b. Verification. Evaluation to determine

that requirements have been met.

c. Mitigation. Elimination of the hazard

entirely or suitable precautions taken to minimize the overall severity to an

acceptable level.

10 Physical failure analysis.

a. Only single common cause events or

failures need to be addressed during the physical failure analysis as

described in this AMC and shown on the left hand sides of Flowcharts 1 and 2.

Multiple common cause events or failures need not be addressed.

b. In relation to physical effects, it

should be assumed that wires are carrying electrical energy and that, in the

case of an EWIS failure, this energy may result in hazardous or catastrophic

effects directly or when combined with other factors, for example fuel,

oxygen, hydraulic fluid, or damage by passengers, These failures may result in

fire, smoke, emission of toxic gases, damage to co-located systems and

structural elements or injury to personnel. This analysis considers all EWIS

from all systems (autopilot, auto throttle, PA system, IFE systems, etc.)

regardless of the system criticality.

Flowchart 1: Pre- and Post-Type

Certification Safety Analysis Concept

Note: Mitigation as used in this flowchart means

to eliminate the hazard entirely or minimise its severity to an acceptable

level.

11 Descriptive

text for flowchart 1

a. Box A: Aircraft functional hazard

assessment.

(1) The functional failure analysis assumes

that electrical wires are carrying power, signal, or information data. Failure

of EWIS under these circumstances may lead to aircraft system degradation

effects.

(2) The functional hazard assessment (FHA)

referred to in this box is not a stand-alone separate document specifically

created to show compliance with CS 25.1709. It is the aircraft level FHA that

the applicant will have developed in compliance with CS 25.1309 to help demonstrate acceptability

of a design concept, identify potential problem areas or desirable design

changes, or determine the need for and scope of any additional analyses (refer

to AMC 25.1309)

b. Analysis of Possible Physical Failures

(1) Box B: EWIS characteristics.

Use the

results of the FHA (BOX A and BOX J) to identify EWIS installation criteria

and definitions of component characteristics. Results from BOX B are fed into

the preliminary system safety analysis (PSSA) and system safety analysis (SSA)

of BOX J.

(2) Boxes C, D and E: Validation and

verification of installation criteria.

(i) Ensure that the EWIS component

qualification satisfies the design requirements and that components are

selected, installed, and used according to their qualification characteristics

and the aircraft constraints linked to their location (refer to the requirements

of CS 25.1703 and CS 25.1707).

(ii) Use available information (digital

mock-up, physical mock-up, aeroplane data, historical data) to perform

inspections and analyses to validate that design and installation criteria are

adequate to the zone/function, including considerations of multi-systems

impact. Such inspections and analyses may include a 1st article inspection,

design review, particular risk assessment, zonal safety assessment, zonal

inspection, and common mode analysis, as applicable. Use such assessments and

inspections to ascertain whether design and installation criteria were

correctly applied. Special consideration should be given to known problem

areas identified by service history and historical data (areas of arcing,

smoke, loose clamps, chafing, arc tracking, interference with other systems,

etc.). Regardless of probability, any single arcing failure should be assumed

for any power-carrying wire. The intensity and consequence of the arc and its

mitigation should be substantiated. Give special consideration to cases where

new (previously unused) material or technologies are used. In any case CS 25.1703(b)

requires that the selection of wires must take into account known

characteristics in relation to each installation and application to minimise

the risk of wire damage, including any arc tracking phenomena.

(iii) Deviations from installation and component

selection criteria identified by these activities should be evaluated. A

determination can then be made about their acceptability. Develop alternative

mitigation strategies as necessary.

(3) Boxes F and G: Development and validation

of mitigation strategy.

Identify and

develop a mitigation strategy for the physical failures and their adverse

effects identified in Boxes D and E. Validation and verification of the

mitigation solution should ensure that:

(i) Hazardous failure conditions are

extremely remote.

(ii) Catastrophic failure conditions do not

result from a single common cause event or failure.

(iii) This mitigation solution does not

introduce any new potential failure conditions.

(4) Box H: Incorporation of applicable

mitigation strategies.

Incorporate

newly developed mitigation strategies (BOX F) into guidelines (BOX B) for

further design and inspection and analysis processes.

(5) Box I: Physical failure analysis results.

From the

EWIS physical failure analysis, the following should be documented:

—

Physical

failures addressed.

—

Effects

of those physical failures.

—

Mitigation

strategies developed.

This

information should be used to support the final analysis documentation (BOX P).

c. Analysis of Possible Functional Failures

(1) Box J: System safety assessments.

The results

of the aeroplane level FHA (BOX A) should be used to guide the system level

FHA (BOX J). Incorporate EWIS failures identified by CS 25.1709 into the

system level and aircraft level FHA, the PSSA, the Common Cause Analyses

(CCA), and the SSA. These analyses are performed to satisfy requirements of CS 25.1309. Use results of these analyses to

update the EWIS definition (BOX B).

(2) Boxes K, L and M: Hazardous and

catastrophic failure conditions.

Use the

analyses in BOX J to determine if the EWIS associated with the system under

analysis can contribute (in whole or in part) to the failure condition under

study. Determine whether the EWIS failure needs to be mitigated. If so,

develop, validate, and verify a mitigation strategy. If no mitigation is

needed, complete the appropriate safety assessment per CS 25.1309, CS 25.671, etc..

(3) Boxes N and O: Development and validation

of mitigation strategy.

Identify and

develop a mitigation strategy for the functional failures and adverse effects

identified in BOX J. Validation and verification of the mitigation solution

should determine if initial objective is fully reached; and confirm that this

mitigation solution is compatible with existing installations and installation

criteria. If the EWIS was the failure cause, the subsequent mitigation

strategy developed may introduce new adverse effects not previously identified

by the analysis. Check for any new adverse effects and update the aircraft

level FHA and other system safety assessments as necessary.

(4) Box P: Documentation of EWIS safety

analysis results.

After

mitigation strategies have been validated and verified, the results of the CS 25.1709 analysis should be documented. Update as necessary the aircraft level

FHA that has been developed in support of certification of the proposed

modification, in compliance with CS 25.1309 (BOX A).

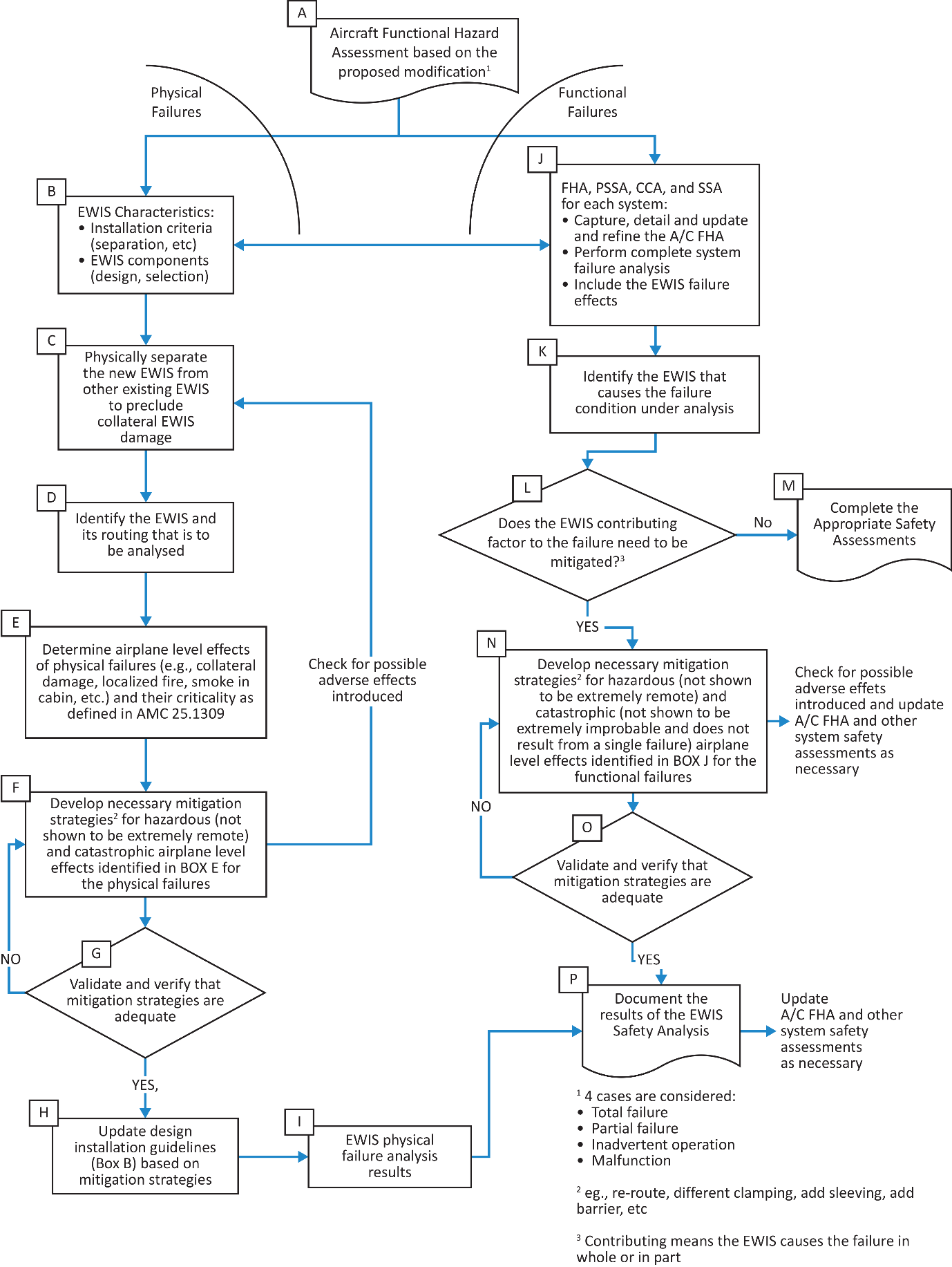

Flowchart 2: Post-TC Safety

Analysis Concept

Note: Mitigation as used in this flowchart means to

eliminate the hazard entirely or minimise its severity to an acceptable level.

12 Descriptive

text for flowchart 2.

a. Applicants for post-TC modifications

should use the analysis depicted in Flowchart 2 when the applicant cannot

identify the systems or systems functions contained in existing aircraft EWIS

that maybe utilized as part of the modification. An applicant should not add

EWIS to an existing EWIS if the systems or systems functions contained in the

existing EWIS are unknown. To do so could introduce unacceptable hazards. For

example, IFE power wires could inadvertently be routed with aeroplane autoland

EWIS.

b. The main objectives are to ensure that

the proposed modification will be correctly designed and installed and will

not introduce unacceptable hazards either through its own failure or by

adversely affecting existing aircraft systems. As far as EWIS is concerned,

correct incorporation of the modification should be ensured by both good

knowledge of original aircraft manufacturer installation practices and their

correct implementation or by adequate separation of the added EWIS from

existing EWIS. In either case, physical analyses should be performed (similar

to the physical failures part of Flowchart 1).

c. Box A: Aircraft functional hazard

assessment.

Aircraft

level effects must be considered for modified systems or systems added to the

aircraft. If the Aircraft level FHA is available, the applicant should examine

it to determine the Aircraft level effect of the proposed modification. If the

Aircraft level FHA is not available, then the applicant must generate an

Aircraft level FHA based on the proposed modification. This Aircraft level FHA

would be limited to just those Aircraft systems affected by the proposed

modification. If it is determined that no Aircraft level functional effects

are introduced, a statement to this effect and the supporting data is

sufficient to satisfy BOX A.

d. Analysis of Possible Physical Failures

(1) Box B: EWIS characteristics.

Use results

of the Aircraft level FHA (BOX A and BOX J) to identify EWIS installation

criteria and definitions of component characteristics. Results of BOX B are

fed into the PSSA and SSA of BOX J.

(2) Box C: Physical separation of new EWIS

from existing EWIS.

(i) The EWIS to be added should be separated

from existing aeroplane EWIS since the systems or system functions contained

in the existing EWIS are unknown. Physical separation between the new and

existing EWIS should be established either by separation distance or by an

appropriate barrier or other means shown to be at least equivalent to the

physical separation distance when allowed by CS 25.1707.

Alternative methods given in the advisory material for CS 25.1707

provide an acceptable way to determine adequate separation.

(ii) In cases where separation cannot be

maintained because of physical constraints (e.g., terminal strips and

connectors), the applicant should accomplish the appropriate analysis to show

that no adverse failure conditions result from sharing the common device. This

analysis requires knowledge of the systems or system functions sharing the

common device (e.g., terminal strips and connectors).

(3) Box D and E: Validation and verification

of installation criteria.

(i) Ensure that the EWIS component

qualification satisfies the design requirements and that components are

selected, installed, and used according to their qualification characteristics

and the aeroplane constraints linked to their location.

(ii) Use available information (digital

mock-up, physical mock-up, aeroplane data, historical data) to perform

inspections and analyses to validate that design and installation criteria are

adequate to the zone/function, including considerations of multi-systems

impact. Such inspections and analyses may include a 1st article inspection,

design review, particular risk assessment, zonal safety assessment, zonal

inspection, and common mode analysis, as applicable. Use such assessments and

inspections to ascertain whether design and installation criteria were

correctly applied. Special consideration should be given to known problem

areas identified by service history and historical data (areas of arcing,

smoke, loose clamps, chafing, arc tracking, interference with other systems,

etc.). Regardless of probability, any single arcing failure should be assumed

for any power-carrying wire. The intensity and consequence of the arc and its

mitigation should be substantiated. Special consideration should be given to cases

where new (previously unused) material or technologies are used. Evaluate

deviations from installation and component selection criteria identified by

these activities and determine their acceptability.

(iii) Alternative mitigation strategies should

be developed as necessary.

(4) Boxes F and G: Development and validation

of mitigation strategy.

Identify and

develop a mitigation strategy for the physical failures identified in BOXES D

and E and resulting adverse effects. Validation and verification of a

mitigation solution should ensure that:

(i) Hazardous failure conditions are

extremely remote.

(ii) Catastrophic failure conditions do not

result from a single common cause event or failure.

(iii) This mitigation solution does not

introduce any new potential failure conditions.

(5) Box H: Incorporation of Applicable

Mitigation Strategies.

Incorporate

newly developed mitigation strategies (BOX F) into guidelines (BOX B) for

further design and inspection and analysis process.

(6) Box I: Physical failure analysis

documentation.

From the

EWIS physical failure analysis, the following should be documented:

—

Physical

failures addressed.

—

Effects

of those physical failures.

—

Mitigation

strategies developed.

This

information supports the final analysis documentation (BOX P).

e. Analysis of Possible Functional Failures

(1) Box J: System safety assessments.

Use the

results of the aircraft level FHA (BOX A) to guide the system level FHA

(BOX J). Incorporate EWIS failures identified by CS 25.1709

into the system level and aircraft level FHA, the PSSA, the CCA, and the SSA.

These analyses are performed to satisfy requirements of CS 25.1309. Use results of these analyses to

update the EWIS definition (BOX B).

(2) Boxes K, L and M: Hazardous and

catastrophic failure conditions.

Use the

analyses in BOX J to determine if the EWIS associated with the system under

analysis can contribute (in whole or in part) to the failure condition under

study. Determine whether the EWIS failure needs to be mitigated. If so,

develop, validate, and verify a mitigation strategy. If no mitigation is

needed, complete the appropriate safety assessment (e.g., per CS 25.1309,

CS 25.671, etc.).

(3) Boxes N and O: Development and validation

of mitigation strategy.

Identify and

develop a mitigation strategy for the functional failures and adverse effects

identified in BOX J. Validation and verification of the mitigation solution

should determine if initial objective is fully reached and confirm that this

mitigation solution is compatible with existing installations and installation

criteria. If the EWIS was the failure cause, the subsequent mitigation

strategy developed may introduce new adverse effects not previously identified

by the analysis. Check for any new adverse effects and update the aircraft

level FHA and other system safety assessments as necessary.

(4) Box P: Documentation of EWIS safety

analysis results.

After

mitigation strategies have been validated and verified, document the results

of the CS 25.1709 analysis. Update as necessary the aircraft

level FHA that has been developed in support of certification of the proposed

modification, in compliance with CS 25.1309, (BOX A).

[Amdt

25/5]