AMC 25.1302 Installed Systems and Equipment for Use by the Flight

Crew

ED

Decision 2007/010/R

Table of content

1. Purpose

2. Background

3. Scope

and Assumptions

4. Certification

Planning

5. Design

Considerations and Guidance

6. Means

of Compliance

Appendix

1: Related Regulatory Material

Appendix

2: Definitions and Acronyms

1. PURPOSE

This

Acceptable Means of Compliance (AMC) provides guidance material for

demonstrating compliance with the requirements of CS 25.1302 and several other paragraphs in

CS-25 that relate to the installed equipment used by the flight crew in the

operation of an aeroplane. In particular, this AMC addresses the design and

approval of installed equipment intended for the use of flight-crew members

from their normally seated positions on the flight deck. This AMC also

provides recommendations for the design and evaluation of controls, displays,

system behaviour, and system integration, as well as design guidance for error

management.

Applicants should use Paragraphs 4, 5 and 6 of this AMC together to

constitute an acceptable means of compliance. Paragraph 4 “Certification

Planning”, describes the activities and communication between the applicant

and the Agency for certification planning. Paragraph 5 “Design Considerations

and Guidance”, is organised in accordance with the sub-paragraphs of CS 25.1302 and identifies HF related design issues that

should be addressed to show compliance with CS 25.1302 and other relevant

rules. Paragraph 6 “Means of Compliance” describes general means of compliance

and how they may be used.

2. BACKGROUND

Flight crews

make a positive contribution to the safety of the air transportation system

because of their ability to assess continuously changing conditions and

situations, analyse potential actions, and make reasoned decisions. However,

even well trained, qualified, healthy, alert flight-crew members make errors.

Some of these errors may be influenced by the design of the systems and their

flight crew interfaces, even with those that are carefully designed. Most of

these errors have no significant safety effects, or are detected and/or

mitigated in the normal course of events,. Still, accident analyses have

identified flight crew performance and error as significant factors in a

majority of accidents involving transport category aeroplanes.

Accidents

most often result from a sequence or combination of errors and safety related

events (e.g., equipment failure and weather conditions). Analyses show that

the design of the flight deck and other systems can influence flight crew task

performance and the occurrence and effects of some flight crew errors.

Some current

regulatory requirements mean to improve aviation safety by requiring that the

flight deck and its equipment be designed with certain capabilities and

characteristics. Approval of flight deck systems with respect to

design-related flight crew error has typically been addressed by referring to

system specific or general applicability requirements, such as CS 25.1301(a), CS 25.771(a), and CS 25.1523. However, little or no guidance

exists to show how the applicant may address potential crew limitations and

errors. That is why CS 25.1302 and this guidance material have

been developed.

Often,

showing compliance with design requirements that relate to human abilities and

limitations is subject to a great deal of interpretation. Findings may vary

depending on the novelty, complexity, or degree of integration related to

system design. The EASA considers that guidance describing a structured

approach to selecting and developing acceptable means of compliance is useful

in aiding standardised certification practices.

This AMC provides guidance for showing compliance with CS 25.1302 and guidance related to several

other requirements associated with installed equipment the flight crew uses in

operating the aeroplane. Table 1 below contains a list of requirements related

to flight deck design and flight crew interfaces for which this AMC provides

guidance. Note that this AMC does not provide a comprehensive means of

compliance for any of the requirements beyond CS 25.1302.

This material applies to flight crew

interfaces and system behaviour for installed systems and equipment used by

the flight crew on the flight deck while operating the aeroplane in normal and

non-normal conditions. It applies to those aeroplane and equipment design

considerations within the scope of CS-25 for type certificate and supplemental

type certificate (STC) projects. It does not apply to flight crew training,

qualification, or licensing requirements. Similarly, it does not apply to

flight crew procedures, except as required within CS-25.

In showing compliance to the requirements

referenced by this AMC, the applicant may assume a qualified flight crew

trained in the use of the installed equipment. This means a flight crew that

is allowed to fly the aeroplane by meeting the requirements in the operating

rules for the relevant Authority.

Paragraph 3 - Table 1: Requirements relevant

to this AMC.

|

CS-25

BOOK 1 Requirements |

General

topic |

Referenced

material in this AMC |

|

CS 25.771(a) |

Unreasonable concentration or fatigue |

Error, 5.6. Integration, 5.7. Controls, 5.3. System Behaviour, 5.5. |

|

CS 25.771(c) |

Controllable from either pilot seat |

Controls, 5.3. Integration, 5.7. |

|

CS 25.773 |

Pilot compartment view |

Integration, 5.7. |

|

CS 25.777(a) |

Location of cockpit controls. |

Controls, 5.3. Integration, 5.7. |

|

CS 25.777(b) |

Direction of movement of cockpit controls |

Controls, 5.3. Integration, 5.7. |

|

CS 25.777(c) |

Full and unrestricted movement of controls |

Controls, 5.3. Integration, 5.7. |

|

CS 25.1301(a) |

Intended function of installed systems |

Error, 5.6. Integration, 5.7. Controls, 5.3. Presentation of Information, 5.4. System Behaviour, 5.5. |

|

CS 25.1302 |

Flight crew error |

Error, 5.6. Integration, 5.7. Controls, 5.3. Presentation of Information, 5.4. System Behaviour, 5.5. |

|

CS 25.1303 |

Flight and navigation instruments |

Integration, 5.7. |

|

CS 25.1309(a) |

Intended function of required equipment under all operating

conditions |

Controls, 5.3. Integration, 5.7. |

|

CS 25.1309(c) |

Unsafe system operating conditions and minimising crew errors which

could create additional hazards |

Presentation of information, 5.4. Errors, 5.6. |

|

CS 25.1321 |

Visibility of instruments |

Integration, 5.7. |

|

CS 25.1322 |

Warning caution and advisory lights |

Integration, 5.7. |

|

CS 25.1329 |

Autopilot, flight director and autothrust |

System Behaviour, 5.5. |

|

CS 25.1523 |

Minimum flight crew |

Controls, 5.3. Integration, 5.7. |

|

CS 25.1543(b) |

Visibility of instrument markings |

Presentation of Information, 5.4. |

|

CS 25.1555 (a) |

Control markings |

Controls, 5.3. |

|

CS 25 Appendix D |

Criteria for determining minimum flight crew |

Integration, 5.7. |

CS 25.1302 is a general applicability

requirement. Other CS-25 requirements exist for specific equipment and

systems. Where guidance in other AMCs is provided for specific equipment and

systems, that guidance is assumed to have precedence if a conflict exists with

guidance provided here. Appendix 1 of this AMC lists references to other related regulatory material and

documents.

This

paragraph describes applicant activities, communication between the applicant

and the Agency, and the documentation necessary for finding compliance in

accordance with this AMC. Requirements for type certification related to

complying with CS-25 may be found in Part 21.

Applicants

can gain significant advantages by involving the Agency in the earliest

possible phases of application and design. This will enable timely agreements

on potential design related human factors issues to be reached and thereby

reduce the applicant’s risk of investing in design features that may not be

acceptable to the Agency.

Certain

activities that typically take place during development of a new product or a

new flight deck system or function, occur before official certification data

is submitted to demonstrate compliance with the requirements. The applicant

may choose to discuss or share these activities with the Agency on an

information-only basis. Where appropriate, the Agency may wish to participate

in assessments the applicant is performing with mock-ups, prototypes, and

simulators.

When the

Agency agrees, as part of the certification planning process, that a specific

evaluation, analysis, or assessment of a human factors issue will become part

of the demonstration that the design is in compliance with requirements, that

evaluation, analysis, or assessment is given “certification credit”.

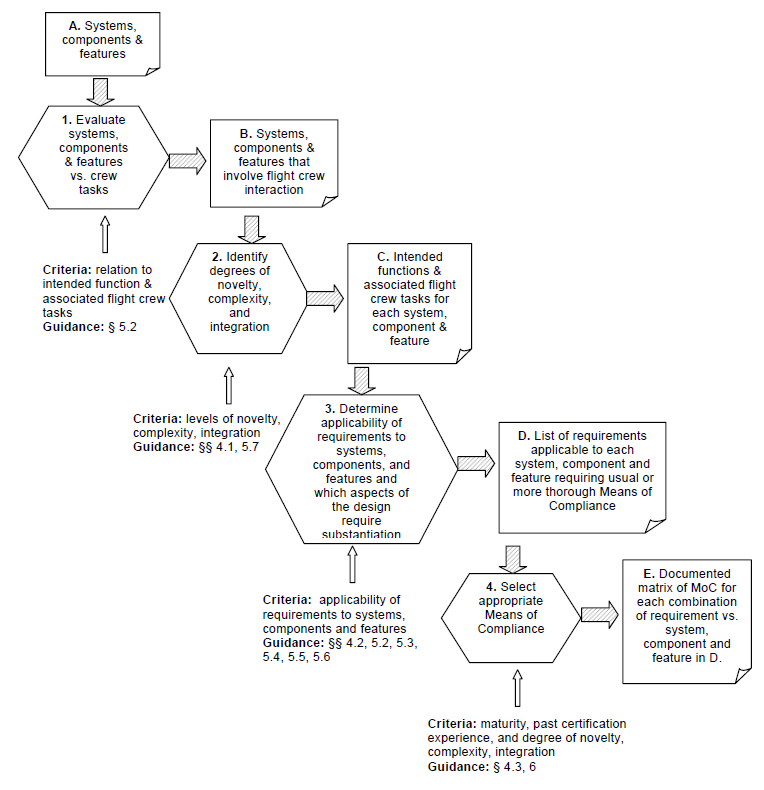

Figure 1

illustrates the interaction between paragraph 4, 5 and 6 of this AMC. These

paragraphs are used simultaneously during the certification process. Paragraph

4 details applicant activities and communication between the applicant and the

Agency. Paragraph 5 provides means of compliance on specific topics.

Paragraphs 5.2, 5.6 and 5.7 assist the applicant in determining inputs

required for the scoping discussions outlined in paragraph 4.1. Paragraphs 5.3

through 5.5 provide guidance in determining the list of applicable

requirements for discussion, outlined in paragraph 4.2. Paragraph 6 provides a

list of acceptable general means of compliance used to guide the discussions

for paragraph 4.3. Paragraph 4.4 lists items that may be documented as a

result of the above discussions.

Paragraph

4 - Fig. 1: Methodical approach to planning certification for design related

Human performance issues

4.1 Scope of the flight deck certification

programme

This

paragraph provides means of establishing the scope of the certification

programme.

In a process

internal to the applicant, the applicant should consider the flight deck

controls, information and system behaviour that involve flight crew

interaction. The applicant should relate the intended functions of the

system(s), components and features to the flight crew tasks. The objective is

to improve understanding about how flight crew tasks might be changed or

modified as a result of introducing the proposed system(s), components and

features. Paragraph 5.2, Intended Function and Associated Flight Crew Tasks,

provides guidance.

The

certification programme may be impacted by the level of integration,

complexity and novelty of the design features, each of which is described in

the sub-paragraphs that follow. Taking these features into account, the

applicant should reach an agreement with the Agency on the scope of flight

deck controls, information and system behaviour that will require extra

scrutiny during the certification process. Applicants should be aware that the

impact of a novel feature might also be affected by its complexity and the

extent of its integration with other elements of the flight deck. A novel but

simple feature will likely require less rigorous scrutiny than one that is

both novel and complex.

a) Integration

In this

document, the term “level of systems integration”, refers to the extent to

which there are interactions or dependencies between systems affecting the

flight crew’s operation of the aeroplane. The applicant should describe such

integration among systems, because it may affect means of compliance.

Paragraph 5.7 also refers to integration. In the context of that paragraph,

integration defines how specific systems are integrated into the flight deck

and how the level of integration may affect the means of compliance.

b) Complexity

Complexity

of the system design from the flight crew’s perspective is an important factor

that may also affect means of compliance in this process. Complexity has

multiple dimensions. The number of information elements the flight crew has to

use (the number of pieces of information on a display, for instance) may be an

indication of complexity. The level of system integration may be a measure of

complexity of the system from the flight crew’s perspective. Design of

controls can also be complex. An example would be a knob with multiple control

modes. Paragraph 5 addresses several

aspects of complexity.

c) Novelty

The

applicant should identify the degree of design novelty based on the following

factors:

—

Are

new technologies introduced that operate in new ways for either established or

new flight deck designs?

—

Are

unusual or additional operational procedures needed as a result of the

introduction of new technologies?

—

Does

the design introduce a new way for the flight crew to interact with systems

using either conventional or innovative technology?

—

Does

the design introduce new uses for existing systems that change the flight

crew’s tasks or responsibilities?

Based on the

above criteria, the applicant should characterise features by their novelty.

More novel features may require extra scrutiny during certification. Less

novel features must still be shown to be compliant with requirements, but will

usually follow a typical certification process that may be less rigorous than

the process described below.

The

applicant should identify design requirements applicable to each of the

systems, components, and features for which means of demonstrating compliance

must be selected. This can be accomplished in part by identifying design

characteristics that can adversely affect flight crew performance, or that

pertain to avoidance and management of flight crew errors.

Specific

design considerations for requirements involving human performance are

discussed in Paragraph 5. The applicability of each design consideration in

Paragraph 5 will depend on the design characteristics identified in paragraph

4.1.

4.3 Select appropriate means of compliance

After

identifying what should be shown in order to demonstrate compliance, the

applicant should review paragraph 6.1 for guidance on selecting the means, or

multiple means of compliance, appropriate to the design. In general, it is

expected that the level of scrutiny or rigour represented by the means of

compliance should increase with higher levels of novelty, complexity and

integration of the design.

Paragraph 6

identifies general means of compliance that have been used on many

certification programmes and discusses their selection, appropriate uses, and

limitations. The applicant may propose other general means of compliance,

subject to approval by the Agency.

Once the

human performance issues have been identified and means of compliance have

been selected and proposed to the Agency, the Agency may agree, as part of the

certification planning process, that a specific evaluation, analysis or

assessment of a human factors issue will become part of the demonstration that

the design is in compliance with requirements. Certification credit can be

granted when data is transmitted to and accepted by the Agency using standard

certification procedures. This data will be a part of the final record of how

the applicant has complied with the requirements.

The output

of this step will consist of the means that will be used to show compliance to

the requirements.

4.4 Certification plan

The

applicant should document the certification process, outputs and agreements

described in the previous paragraphs. This may be done in a separate plan or

incorporated into a higher level certification plan. The following is a

summary of what may be contained in the document:

—

The

new aeroplane, system, control, information or feature(s)

—

The

design feature(s) being evaluated and whether or not the feature(s) is(are)

new or novel

—

The

integration or complexity of the new feature(s)

—

Flight

crew tasks that are affected or any new tasks that are introduced

—

Any

new flight crew procedures

—

Specific

requirements that must be complied with

—

The

means (one or several) that will be used to show compliance

—

The

method for transferring data to the Agency

5. DESIGN CONSIDERATIONS AND GUIDANCE

This paragraph contains a discussion of CS 25.1302 and guidance on complying

with it and other requirements.

The applicant should first complete the

following steps.

—

Identify

systems, components, and features of a new design that are potentially

affected by the requirements.

—

Assess

degrees of novelty, complexity, and level of integration using the initial

process steps in paragraph 4.

Once these steps have been completed, use the

contents of this paragraph to identify what should be shown to demonstrate

compliance.

To comply with the requirements of CS-25, the

design of flight deck systems should appropriately address foreseeable

capabilities and limitations of the flight crew. To aid the applicant in

complying with this overall objective, this paragraph has been divided into

sub-paragraphs. They provide guidance on the following topics:

—

Applicability

and Explanatory material to CS 25.1302 (See paragraph 5.1),

—

Intended

function and associated flight crew tasks(See paragraph 5.2),

—

Controls

(See paragraph 5.3),

—

Presentation

of information(See paragraph 5.4),

—

System

behaviour (See paragraph 5.5),

—

Flight

crew error management(See paragraph 5.6),

—

Integration

(See paragraph 5.7),

Each sub-paragraph discusses what the

applicant should show to establish compliance with applicable requirements. We

are not describing here what might otherwise be referred to as industry “best

practices.” The guidance presented here

is the airworthiness standard for use in compliance. Obviously, not all

criteria can or should be met by all systems. Because the nature of the

guidance in this AMC is broad and general, some of it will conflict in certain

instances. The applicant and the Agency must apply some judgment and

experience in determining which guidance applies to what parts of the design

and in what situations. Headings indicate the regulations to which the

guidance applies. First, however, we provide a more detailed discussion of CS 25.1302.

As described in the Background and Scope

paragraphs of this document, flight crew error is a contributing factor in

accidents. CS 25.1302 was developed to provide a regulatory basis for, and this AMC

provides guidance to address design-related aspects of avoidance and

management of flight crew error by taking the following approach:

First, by providing guidance about design

characteristics that are known to reduce or avoid flight crew error and that

address flight crew capabilities and limitations. Requirements in

sub-paragraphs (a) through (c) of CS 25.1302 are intended to reduce the

design contribution to such errors by ensuring information and controls needed

by the flight crew to perform tasks associated with the intended function of

installed equipment are provided, and that they are provided in a usable form.

In addition, operationally relevant system behaviour must be understandable,

predictable, and supportive of flight crew tasks. Guidance is provided in this

paragraph on the avoidance of design-induced flight crew error.

Second, CS 25.1302(d) addresses the fact that since

flight crew errors will occur, even with a well-trained and proficient flight

crew operating well-designed systems, the design must support management of

those errors to avoid safety consequences. Paragraph 5.6 below on flight crew

error management provides relevant guidance.

5.1 Applicability and Explanatory Material to CS

25.1302

CS-25 contains requirements for the design of

flight deck equipment that are system-specific (e.g., CS 25.777, CS 25.1321, CS 25.1329, CS 25.1543 etc.), generally applicable (e.g.,

CS 25.1301(a), CS 25.1309(c), CS 25.771 (a)), and that establish minimum

flight crew requirements (e.g. CS 25.1523 and CS-25 Appendix D). CS 25.1302 augments previously existing

generally applicable requirements by adding more explicit requirements for

design attributes related to avoidance and management of flight crew error.

Other ways to avoid and manage flight crew error are regulated through requirements

governing licensing and qualification of flight-crew members and aircraft

operations. Taken together, these complementary approaches provide a high

degree of safety.

The complementary approach is important. It is

based upon recognition that equipment design, training/licensing/

qualification, and operations/procedures each provide safety contributions to

risk mitigation. An appropriate balance is needed among them. There have been

cases in the past where design characteristics known to contribute to flight

crew error were accepted based upon the rationale that training or procedures

would mitigate that risk. We now know that this can often be an inappropriate

approach. Similarly, due to unintended consequences, it would not be

appropriate to require equipment design to provide total risk mitigation. If a

flight-crew member misunderstands a controller's clearance, it does not follow

that the Agency should mandate datalink or some other design solution as

Certification Specifications. Operating rules currently require equipment to

provide some error mitigations (e.g., Terrain Awareness and Warning Systems),

but not as part of the airworthiness requirements.

As stated, a proper balance is needed among

design approval requirements in the minimum airworthiness standards of CS-25

and requirements for training/ licensing/ qualification and

operations/procedures. CS 25.1302 and this AMC were developed with the intent of achieving that

appropriate balance.

Introduction The introductory sentence

of CS 25.1302 states that the provisions

of this paragraph apply to each item of installed equipment intended for the

flight crew’s use in operating the aeroplane from their normally seated

positions on the flight deck.

“Intended for the flight-crew member’s use in

the operation of the aeroplane from their normally seated position,” means

that intended function of the installed equipment includes use by the flight

crew in operating the aeroplane. An example of such installed equipment would

be a display that provides information enabling the flight crew to navigate.

The phrase “flight-crew members” is intended to include any or all individuals

comprising the minimum flight crew as determined for compliance with CS

25.1523. The phrase “from their normally seated position” means flight-crew

members are seated at their normal duty stations for operating the aeroplane.

This phrase is intended to limit the scope of this requirement so that it does

not address systems or equipment not used while performing their duties in

operating the aeroplane in normal and non-normal conditions. For example, this

paragraph is not intended to apply to items such as certain circuit breakers

or maintenance controls intended for use by the maintenance crew (or by the

flight crew when not operating the aeroplane).

The words “This installed equipment must be

shown…” in the first paragraph means the applicant must provide sufficient

evidence to support compliance determinations for each of the CS 25.1302 requirements. This is not

intended to require a showing of compliance beyond that required by Part

21A.21(b). Accordingly, for simple items or items similar to previously

approved equipment and installations, we do not expect the demonstrations,

tests or data needed to show compliance with CS 25.1302 to entail more extensive or

onerous efforts than are necessary to show compliance with previous

requirements.

The phrase “individually and in combination

with other such equipment” means that the requirements of this paragraph must

be met when equipment is installed on the flight deck with other equipment.

The installed equipment must not prevent other equipment from complying with

these requirements. For example, applicants must not design a display so that

information it provides is inconsistent or in conflict with information from

other installed equipment.

In addition, provisions of this paragraph

presume a qualified flight crew trained to use the installed equipment. This

means the design must meet these requirements for flight-crew members who are

allowed to fly the aeroplane by meeting operating rules qualification

requirements. If the applicant seeks type design or supplemental type design

approval before a training programme is accepted, the applicant should

document any novel, complex, or highly integrated design features and

assumptions made during design that have the potential to affect training time

or flight crew procedures. The requirement and associated material are written

assuming that either these design features and assumptions, or knowledge of a

training programme (proposed or in the process of being developed) will be

coordinated with the appropriate operational approval organisation when

judging the adequacy of the design.

The requirement that equipment be designed so

the flight crew can safely perform tasks associated with the equipment’s

intended function, applies in both normal and non-normal conditions. Tasks

intended for performance under non-normal conditions are generally those

prescribed by non-normal (including emergency) flight crew procedures. The

phrase “safely perform their tasks” is intended to describe one of the safety

objectives of this requirement. The requirement is that equipment design

enables the flight crew to perform the tasks with sufficient accuracy and in a

timely manner, without unduly interfering with other required tasks. The

phrase “tasks associated with its intended function” is intended to

characterise either tasks required to operate the equipment or tasks for which

the equipment’s intended function provides support.

CS 25.1302(a) requires the applicant to install

appropriate controls and provide necessary information for any flight deck

equipment identified in the first paragraph of CS 25.1302. Controls and information displays

must be sufficient to allow the flight crew to accomplish their tasks.

Although this may seem obvious, this requirement is included because a review

of CS-25 on the subject of human factors revealed that a specific requirement

for flight deck controls and information to meet the needs of the flight crew

is necessary. This requirement is not reflected in other parts of the rules,

so it is important to be explicit.

CS 25.1302(b) addresses requirements for flight deck controls and information that

are necessary and appropriate so the flight crew can accomplish their tasks,

as determined through (a) above. The intent is to ensure that the design of

the control and information devices makes them usable by the flight crew. This

sub-paragraph seeks to reduce design-induced flight crew errors by imposing

design requirements on flight deck information presentation and controls.

Sub-paragraphs (1) through (3) specify these design requirements.

Design requirements for information and

controls are necessary to:

—

Properly

support the flight crew in planning their tasks,

—

Make

available to the flight crew appropriate, effective means to carry-out planned

actions,

—

Enable

the flight crew to have appropriate feedback information about the effects of

their actions on the aeroplane.

CS 25.1302(b)(1) specifically requires that controls and information be provided in

a clear and unambiguous form, at a resolution and precision appropriate to the

task. As applied to information, “clear and unambiguous” means that it:

—

Can

be perceived correctly (is legible).

—

Can

be comprehended in the context of the flight crew task.

—

Supports

the flight crew’s ability to carry out the action intended to perform the

tasks.

For controls, the requirement for “clear and

unambiguous” presentation means that the crew must be able to use them

appropriately to achieve the intended function of the equipment. The general

intent is to foster design of equipment controls whose operation is intuitive,

consistent with the effects on the parameters or states they affect, and

compatible with operation of other controls on the flight deck.

Sub-paragraph CS 25.1302(b)(1) also requires that the

information or control be provided, or operate, at a level of detail and

accuracy appropriate to accomplishing the task. Insufficient resolution or

precision would mean the flight crew could not perform the task adequately.

Conversely, excessive resolution has the potential to make a task too

difficult because of poor readability or the implication that the task should

be accomplished more precisely than is actually necessary.

CS 25.1302(b)(2) requires that controls and

information be accessible and usable by the flight crew in a manner consistent

with the urgency, frequency, and duration of their tasks. For example,

controls used more frequently or urgently must be readily accessed, or require

fewer steps or actions to perform the task. Less accessible controls may be

acceptable if they are needed less frequently or urgently. Controls used less

frequently or urgently should not interfere with those used more urgently or

frequently. Similarly, tasks requiring a longer time for interaction should

not interfere with accessibility to information required for urgent or

frequent tasks.

CS 25.1302(b)(3) requires that equipment presents information advising the flight crew

of the effects of their actions on the aeroplane or systems, if that awareness

is required for safe operation. The intent is that the flight crew be aware of

system or aeroplane states resulting from flight crew actions, permitting them

to detect and correct their own errors.

This sub-paragraph is included because new

technology enables new kinds of flight crew interfaces that previous

requirements don’t address. Specific deficiencies of existing requirements in

addressing human factors are described below:

—

CS 25.771(a) addresses this topic for controls, but does not include criteria for

information presentation.

—

CS 25.777(a) addresses controls, but only their location.

—

CS 25.777(b) and CS 25.779 address direction of motion and actuation but do not encompass new

types of controls such as cursor devices. These requirements also do not

encompass types of control interfaces that can be incorporated into displays

via menus, for example, thus affecting their accessibility.

—

CS 25.1523 and CS-25 Appendix D have a different context and purpose (determining

minimum crew), so they do not address these requirements in a sufficiently

general way.

CS 25.1302(c) requires that installed equipment

be designed so its behaviour that is operationally relevant to flight crew’

tasks is:

—

Predictable

and unambiguous.

—

Designed

to enable the flight crew to intervene in a manner appropriate to the task

(and intended function).

Improved flight deck technologies involving

integrated and complex information and control systems, have increased safety

and performance. However, they have also introduced the need to ensure proper

interaction between the flight crew and those systems. Service experience has

found that some equipment behaviour (especially from automated systems) is

excessively complex or dependent upon logical states or mode transitions that

are not well understood or expected by the flight crew. Such design characteristics

can confuse the flight crew and have been determined to contribute to

incidents and accidents.

The phrase “operationally-relevant behaviour”

is meant to convey the net effect of the equipment’s system logic, controls,

and displayed information upon flight crew awareness or perception of the

system’s operation to the extent that this is necessary for planning actions

or operating the system. The intent is to distinguish such system behaviour

from the functional logic within the system design, much of which the flight

crew does not know or need to know and which should be transparent to them.

CS 25.1302(c)(1) requires that system behaviour be

such that a qualified flight crew can know what the system is doing and why.

It requires that operationally relevant system behaviour be “predictable and

unambiguous”. This means that a crew can retain enough information about what

their action or a changing situation will cause the system to do under

foreseeable circumstances, that they can operate the system safely. System

behaviour must be unambiguous because crew actions may have different effects

on the aeroplane depending on its current state or operational circumstances.

CS 25.1302(c)(2) requires that the design be such

that the flight crew will be able to take some action, or change or alter an

input to the system in a manner appropriate to the task.

CS 25.1302(d) addresses the reality that even well-trained, proficient flight crews

using well-designed systems will make errors. It requires that equipment be

designed to enable the flight crew to manage such errors. For the purpose of

this rule, errors “resulting from flight crew interaction with the equipment”

are those errors in some way attributable to, or related to, design of the

controls, behaviour of the equipment, or the information presented. Examples

of designs or information that could cause errors are indications and controls

that are complex and inconsistent with each other or other systems on the

flight deck. Another example is a procedure inconsistent with the design of

the equipment. Such errors are considered to be within the scope of this

requirement and AMC.

What is meant by design which enables the

flight crew to “manage errors” is that:

—

The

flight crew must be able to detect and/or recover from errors resulting from

their interaction with the equipment, or

—

Effects

of such flight crew errors on the aeroplane functions or capabilities must be

evident to the flight crew and continued safe flight and landing must be

possible, or

—

Flight

crew errors must be discouraged by switch guards, interlocks, confirmation

actions, or other effective means, or

—

Effects

of errors must be precluded by system logic or redundant, robust, or fault

tolerant system design.

The requirement to manage errors applies to

those errors that can be reasonably expected in service from qualified and

trained flight crews. The term “reasonably expected in service” means errors

that have occurred in service with similar or comparable equipment. It also

means error that can be projected to occur based on general experience and

knowledge of human performance capabilities and limitations related to use of

the type of controls, information, or system logic being assessed.

CS 25.1302(d) includes the following

statement: “This sub-paragraph does not apply to skill-related errors

associated with manual control of the aeroplane”. That statement means to

exclude errors resulting from flight crew proficiency in control of flight

path and attitude with the primary roll, pitch, yaw and thrust controls, and

which are related to design of the flight control systems. These issues are

considered to be adequately addressed by existing requirements, such as CS-25

Subpart B and CS 25.671(a). It is not intended that design be required to compensate for

deficiencies in flight crew training or experience. This assumes at least the

minimum flight crew requirements for the intended operation, as discussed at

the beginning of Paragraph 5.1 above.

This requirement is intended to exclude

management of errors resulting from decisions, acts, or omissions by the

flight crew that are not in good faith. It is intended to avoid imposing

requirements on the design to accommodate errors committed with malicious or

purely contrary intent. CS 25.1302 is not intended to require applicants to consider errors resulting

from acts of violence or threats of violence.

This “good faith” exclusion is also intended

to avoid imposing requirements on design to accommodate errors due to obvious

disregard for safety by a flight-crew member. However, it is recognised that

errors committed intentionally may still be in good faith but could be

influenced by design characteristics under certain circumstances. An example

would be a poorly designed procedure not compatible with the controls or

information provided to the flight crew.

The intent of requiring errors to be

manageable only “to the extent practicable” is to address both economic and

operational practicability. It is meant to avoid imposing requirements without

considering economic feasibility and commensurate safety benefits. It is also

meant to address operational practicability, such as the need to avoid

introducing error management features into the design that would

inappropriately impede flight crew actions or decisions in normal or

non-normal conditions. For example, it is not intended to require so many

guards or interlocks on the means to shut down an engine that the flight crew

would be unable to do this reliably within the available time. Similarly, it

is not intended to reduce the authority or means for the flight crew to

intervene or carry out an action when it is their responsibility to do so

using their best judgment in good faith.

This sub-paragraph was included because

managing errors that result from flight crew interaction with equipment (that

can be reasonably expected in service), is an important safety objective. Even

though the scope of applicability of this material is limited to errors for

which there is a contribution from or relationship to design, CS 25.1302(d) is expected to result in design

changes that will contribute to safety. One example, among others, would be

the use of an "undo" functions in certain designs.

5.2 Intended Function and Associated Flight Crew Tasks

CS 25.1301(a) requires that: “each item of

installed equipment must - (a) Be of a kind and design appropriate to its

intended function”. CS 25.1302 establishes requirements to ensure the design supports flight-crew

member’s ability to perform tasks associated with a system’s intended

function. In order to show compliance with CS 25.1302, the intended function of a system

and the tasks expected of the flight crew must be known.

An applicant’s statement of intended function

must be sufficiently specific and detailed that the Agency can evaluate

whether the system is appropriate for the intended function(s) and the

associated flight crew tasks. For example, a statement that a new display

system is intended to “enhance situation awareness” must be further explained.

A wide variety of different displays enhance situation awareness in different

ways. Examples are; terrain awareness, vertical profile, and even the primary

flight displays). The applicant may need more detailed descriptions for

designs with greater levels of novelty, complexity or integration.

An applicant should describe intended

function(s) and associated task(s) for:

—

Each

item of flight deck equipment,

—

Flight

crew indications and controls for that equipment,

—

Individual

features or functions of that equipment.

This type of information is of the level

typically provided in a pilot handbook or an operations manual. It would

describe indications, controls, and flight crew procedures.

As discussed in paragraph 4, novel features

may require more detail, while previously approved systems and features

typically require less. Paragraph 4.1 discusses functions that are

sufficiently novel that additional scrutiny is required. Applicants may

evaluate whether statements of intended function(s) and associated task(s) are

sufficiently specific and detailed by using the following questions:

—

Does

each feature and function have a stated intent?

—

Are

flight crew tasks associated with the function described?

—

What

assessments, decisions, and actions are flight-crew members expected to make

based on information provided by the system?

—

What

other information is assumed to be used in combination with the system?

—

Will

installation or use of the system interfere with the ability of the flight

crew to operate other flight deck systems?

—

Are

there any assumptions made about the operational environment in which the

equipment will be used?

—

What

assumptions are made about flight crew attributes or abilities beyond those

required in regulations governing flight operations, training, or

qualification?

For purposes of this AMC, we define controls

as devices the flight crew manipulates in order to operate, configure, and

manage the aeroplane and its flight control surfaces, systems, and other

equipment. This may include equipment in the flight deck such as;

—

Buttons

—

Switches

—

Knobs

—

Keyboards

—

Keypads

—

Touch

screens

—

Cursor

control devices

—

Graphical

user interfaces, such as pop-up windows and pull-down menus that provide

control functions

—

Voice

activated controls

5.3.2 Showing

Compliance with CS 25.1302(b)

Applicants should propose means of compliance

to show that controls in the proposed design comply with CS 25.1302(b). The proposed means should be

sufficiently detailed to demonstrate that each function, method of control

operation, and result of control actuation complies with the requirements,

i.e.:

—

Clear

—

Unambiguous

—

Appropriate

in resolution and precision

—

Accessible

—

Usable

—

Enables

flight crew awareness (provides adequate feedback)

For each of these requirements, the proposed

means of compliance should include consideration of the following control

characteristics for each control individually and in relation to other

controls:

—

Physical

location of the control

—

Physical

characteristics of the control (e.g., shape, dimensions, surface texture,

range of motion, colour)

—

Equipment

or system(s) that the control directly affects

—

How

the control is labelled

—

Available

control settings

—

Effect

of each possible actuation or setting, as a function of initial control

setting or other conditions

—

Whether

there are other controls that can produce the same effect (or affect the same

target parameter) and conditions under which this will happen

—

Location

and nature of control actuation feedback

The following discussion provides additional

guidance for design of controls that comply with CS 25.1302. It also provides industry

accepted best practices.

5.3.3 Clear and Unambiguous Presentation of Control

Related Information

a. Distinguishable

and Predictable Controls [CS 25.1301(a), CS 25.1302]

Each flight-crew member should be able to

identify and select the current function of the control with speed and

accuracy appropriate to the task. Function of a control should be readily

apparent so that little or no familiarisation is required. The applicant

should evaluate consequences of control activation to show they are

predictable and obvious to each flight-crew member. This includes control of

multiple displays with a single device and shared display areas that

flight-crew members access with individual controls. Controls can be made

distinguishable or predictable by differences in form, colour, location,

and/or labelling. Colour coding is usually not sufficient as a sole

distinguishing feature. This applies to physical controls as well as to controls

that are part of an interactive graphical user interface.

b. Labelling

[CS 25.1301(a), CS 25.1543(b), CS 25.1555(a)]

For general marking of controls see CS 25.1555(a). Labels should be readable from

the crewmember’s normally seated position in all lighting and environmental

conditions. If a control performs more than one function, labelling should

include all intended functions unless function of the control is obvious.

Labels of graphical controls accessed by a cursor device such as a trackball

should be included on the graphical display. When menus lead to additional

choices (submenus), the menu label should provide a reasonable description of

the next submenu.

The applicant can label with text or icons.

Text and icons should be shown to be distinct and meaningful for the function

that they label. The applicant should use standard and/or non-ambiguous

abbreviations, nomenclature, or icons, consistent within a function and across

the flight deck. ICAO 8400 provides standard abbreviations and is an

acceptable basis for selection of labels.

The design should avoid hidden functions (such

as clicking on empty space on a display to make something happen), However,

such hidden functions may be acceptable if adequate alternate means are

available for accessing the function. The design should still be evaluated for

ease of use and crew understanding.

When using icons instead of text labelling,

the applicant should show that the flight crew requires only brief exposure to

the icon to determine the function of a control and how it operates. Based on

design experience, the following guidelines for icons have been shown to lead

to usable designs:

—

The

icon should be analogous to the object it represents

—

The

icon should be in general use in aviation and well known to flight crews

—

The

icon should be based on established standards, when they exist, and

conventional meanings.

In all cases, the applicant should show use of

icons to be at least equivalent to text labels in terms of speed and error

rate. Alternatively, the applicant should show that the increased error rate

or task times have no unacceptable effect on safety or flight crew workload

and do not cause flight crew confusion.

c. Interaction

of Multiple Controls [CS 25.1302]

If multiple controls for the flight crew are

provided for a function, the applicant should show that there is sufficient

information to make the flight crew aware of which control is currently

functioning. As an example, crewmembers need to know which flight-crew

member’s input has priority when two cursor control devices can access the

same display. Designers should use caution when dual controls can affect the

same parameter simultaneously.

5.3.4 Accessibility of controls [CS 25.771(a), CS 25.777(b), CS 25.1302]

The applicant must show that each flight-crew

member in the minimum flight crew, as defined by CS 25.1523, has access to and

can operate all necessary controls. Accessibility is one factor in determining

whether controls support the intended function of equipment used by the flight

crew. Any control required for flight-crew member operation in the event of incapacitation

of other flight-crew members (in both normal and non-normal conditions) must

be shown to be viewable, reachable, and operable by flight-crew members with

the stature specified in CS 25.777(c), from the seated position with shoulder restraints on. If shoulder

restraints are lockable, this may be shown with shoulder restraints unlocked.

CS 25.777(c) requires that the location and

arrangement of each flight deck control permit full and unrestricted movement

of that control without interference from other controls, equipment, or

structure in the flight deck.

Layering of information, as with menus or

multiple displays, should not hinder flight crew in identifying the location

of the desired control. In this context, location and accessibility are not

only the physical location of the control function (on a display device) or

any multifunction control (for example,, a cursor control device) used to

access them. Location and accessibility also includes consideration of where

the control functions may be located within various menu layers and how the

flight-crew member navigates those layers to access the functions.

Accessibility should be shown in conditions of system failures (including crew

incapacitation) and minimum equipment list dispatch.

Control position and direction of motion

should be oriented from the vantage point of the flight-crew member.

Control/display compatibility should be maintained from that regard. For

example, a control on an overhead panel requires movement of the flight-crew

member’s head backwards and orientation of the control movement should take

this into consideration.

5.3.5 Use of controls

a. Environmental

issues affecting controls [CS 25.1301(a) and CS 25.1302]

Turbulence or vibration and extremes in

lighting levels should not prevent the crew from performing all their tasks at

an acceptable level of performance and workload. If use of gloves is

anticipated for cold weather operations, the design should account for the

effect of their use on the size and precision of controls. Sensitivity of

controls should afford precision sufficient to perform tasks even in adverse

environments as defined for the aeroplane’s operational envelope. Analysis of

environmental issues as a means of compliance (see 6.3.3) is necessary, but

not sufficient for new control types or technologies or for novel use of

controls that are themselves not new or novel.

The applicant should show that controls

required to regain aeroplane or system control and controls required to

continue operating the aeroplane in a safe manner are usable in conditions

such as dense smoke in the flight deck or severe vibrations. An example of the

latter condition would be after a fan blade loss.

b. Control-display

compatibility [CS 25.777(b)]

To ensure that a control is unambiguous, the

relationship and interaction between a control and its associated display or indications

should be readily apparent, understandable, and logical. A control input is

often required in response to information on a display or to change a

parameter setting on a display. The applicant should specifically asses any

rotary knob that has no obvious “increase” or “decrease” function with regard

to flight crew expectations and its consistency with other controls on the

flight deck. The Society of Automotive Engineers’ (SAE) publication ARP 4102,

section 5.3, is an acceptable means of compliance for controls used in flight

deck equipment.

When a control is used to move an actuator

through its range of travel, the equipment should provide, within the time

required for the relevant task, operationally significant feedback of the

actuator’s position within its range. Examples of information that could

appear relative to an actuator’s range of travel include trim system

positions, target speed, and the state of various systems valves.

Controls associated with a display should be

located so that they do not interfere with the performance of the crew task.

Controls whose function is specific to a particular display surface should be

mounted near to the display or function being controlled. Locating controls

immediately below a display is generally preferable as mounting controls

immediately above a display has, in many cases, caused the flight-crew

member’s hand to obscure viewing of the display when operating controls.

However, controls on the bezel of multifunction displays have been found to be

acceptable.

Spatial separation between a control and its

display may be necessary. This is the case with a system’s control located

with others for that same system, or when it is one of several controls on a

panel dedicated to controls for that multifunction display. When there is

large spatial separation between a control and its associated display, the

applicant should show that use of the control for the associated task(s), is

acceptable in terms of types of errors, error rate(s) and access time(s).

In general, control design and placement

should avoid the possibility that the visibility of information could be

blocked. If range of control movement temporarily blocks the flight crew’s

view of information, the applicant should show that this information is either

not necessary at that time or available in another accessible location.

Annunciations/labels on electronic displays

should be identical to labels on related switches and buttons located

elsewhere on the flight deck. If display labels are not identical to related

controls, the applicant should show that flight-crew members can quickly,

easily, and accurately identify associated controls.

5.3.6 Adequacy of Feedback [CS 25.771(a), CS 25.1301(a), CS 25.1302)]

Feedback for control inputs is necessary to

give the flight crew awareness of the effects of their actions. Each control

should provide feedback to the crewmember for menu selections, data entries,

control actions, or other inputs. There should be clear and unambiguous

indication when crew input is not accepted or followed by the system. This

feedback can be visual, auditory, or tactile. Feedback, in whatever form,

should be provided to inform the crew that:

—

A

control has been activated (commanded state/value)

—

The

function is in process (given an extended processing time)

—

The

action associated with the control has been initiated (actual state/value if

different from the commanded state).

The type, duration and appropriateness of

feedback, will depend upon the crew’s task and the specific information

required for successful operation. As an example, switch position alone is

insufficient feedback if awareness of actual system response or the state of

the system as a result of an action is required.

Controls that may be used while the user is

looking outside or at unrelated displays should provide tactile feedback.

Keypads should provide tactile feedback for any key depression. In cases when

this is omitted, it should be replaced with appropriate visual or other

feedback that the system has received the inputs and is responding as

expected.

Equipment should provide appropriate visual

feedback, not only for knob, switch, and pushbutton position, but also for

graphical control methods such as pull-down menus and pop-up windows. The user

interacting with a graphical control should receive positive indication that a

hierarchical menu item has been selected, a graphical button has been

activated, or other input has been accepted.

The applicant should show that feedback in all

forms is obvious and unambiguous to the flight crew in performance of the

tasks associated with the intended function of the equipment.

5.4 Presentation of Information

Applicants should propose means of compliance

to show that information displayed in the proposed design complies with CS 25.1302(b). The proposed means should be

sufficiently detailed to show that the function, method of control operation

and result, complies with the requirements, i.e.:

—

Clear

—

Unambiguous

—

Appropriate

in resolution and precision

—

Accessible

—

Usable

—

Enables

Flight Crew awareness (provides adequate feedback)

Presentation of information to the flight crew

can be visual (for instance, on an LCD), auditory (a “talking” checklist) or

tactile (for example, control feel). Information presentation on the

integrated flight deck, regardless of the medium used, should meet all of the

requirements bulleted above. For visual displays, this AMC addresses mainly

display format issues and not display hardware characteristics. The following

provides design considerations for requirements found in CS 25.1301(a), CS 25.1301(b), CS 25.1302, and CS 25.1543(b). In the event of a conflict

between this document and AMC 25-11 regarding guidance on specific electronic

visual display functions, AMC 25-11 takes precedence.

5.4.2 Clear and Unambiguous Presentation of

Information

a. Qualitative

and quantitative display formats [CS 25.1301(a) and CS 25.1302]

Applicants should show that display formats

include the type of information the flight crew needs for the task,

specifically with regard to the speed and precision of reading required. For example, the information could be in the

form of a text message, numerical value, or a graphical representation of

state or rate information). State information identifies the specific value of

a parameter at a particular time. Rate information indicates the rate of

change of that parameter.

If the flight crew’s sole means of detecting

non-normal values is by monitoring values presented on the display, the

equipment should offer qualitative display formats. Qualitative display

formats better convey rate and trend information. If this is not practical,

the applicant should show that the flight crew can perform the tasks for which

the information is used. Quantitative presentation of information is better

for tasks requiring precise values.

Digital readouts or present value indices

incorporated into qualitative displays should not make the scale markings or

graduations unusable as they pass the present value index.

b. Consistency

[CS 25.1302]

If similar information is presented in

multiple locations or modes (visual and auditory, for example), consistent

presentation of information is desirable. Consistency in information

presentation within the system tends to minimise flight crew error. If information

cannot be presented consistently within the flight deck, the applicant should

show that differences do not increase error rates or task times leading to

significant safety or flight crew workload and do not cause flight crew

confusion.

c. Characters,

fonts, lines and scale markings [CS 25.1301(a) and CS 25.1543(b)]

The applicable crew members, seated at their

stations and using normal head movement, should be able to see and read

display format features such as fonts, symbols, icons and markings. In some

cases, cross flight deck readability may be required. Examples of situations

where this might be needed are cases of display failure or when cross checking

flight instruments. Readability must be maintained in sunlight viewing

conditions (per CS 25.773(a)) and under other adverse conditions such as

vibration. Figures and letters should subtend not less than the visual angles

defined in SAE ARP 4102-7 at the design eye position of the flight-crew member

who normally uses the information.

d. Colour

[CS 25.1302]

Avoid using many different colours to convey

meaning on displays. However, judicious use of colour can be very effective in

minimising display interpretation workload and response time. Colour can be

used to group logical electronic display functions or data types. A common

colour philosophy across the flight deck is desirable, although deviations may

be approved with acceptable justification. Applicants should show that the

chosen colour set is not susceptible to confusion or misinterpretation due to

differences in colour usage between displays. Improper colour coding increases

response times for display item recognition and selection, and increases

likelihood of errors in situations where the speed of performing a task is

more important than accuracy. Extensive use of the colours red and amber for

other than alerting functions or potentially unsafe conditions is discouraged.

Such use diminishes the attention-getting characteristics of true warnings and

cautions.

Use of colour as the sole means of presenting

information is also discouraged. It may be acceptable however, to indicate the

criticality of the information in relation to the task. Colour, when used for

task essential information, should be in addition to other coding

characteristics, such as texture or differences in luminance. AMC 25-11 contains recommended colour sets

for specific display features.

Applicants should show that layering

information on a display does not add to confusion and clutter as a result of

the colour standards and symbols used. Designs requiring flight-crew members

to manually de-clutter such displays should also be avoided.

e. Symbology,

Text, and Auditory Messages [CS 25.1302]

Designs can base many elements of electronic

display formats on established standards and conventional meanings. For

example, ICAO 8400 provides abbreviations and is one standard that could be

applied to flight deck text. SAE ARP 4102-7, Appendix A-C and SAE ARP 5289 are

acceptable standards for avionic display symbols.

The position of a message or symbol within a

display also conveys meaning to the flight-crew member. Without the consistent

or repeatable location of a symbol in a specific area of the electronic

display, interpretation errors and response times may increase. Applicants

should give careful attention to symbol priority (priority of displaying one

symbol overlaying another symbol by editing out the secondary symbol) to

ensure that higher priority symbols remain viewable.

New symbols (a new design or a new symbol for

a function which historically had an associated symbol) should be tested for

distinguishability and flight crew comprehension and retention.

The applicant should show that display text

and auditory messages are distinct and meaningful for the information

presented. Assess messages for whether they convey the intended meaning.

Equipment should display standard and/or non-ambiguous abbreviations and

nomenclature, consistent within a function and across the flight deck.

5.4.3 Accessibility and Usability of Information

a. Accessibility

of information [CS 25.1302]

Some information may at certain times be

immediately needed by the flight crew, while other information may not be

necessary during all phases of flight. The applicant should show that the

flight crew can access and manage (configure) all necessary information on the

dedicated and multifunction displays for the phase of flight. The applicant

should show that any information required for continued safe flight and

landing is accessible in the relevant degraded display modes following

failures as defined by CS 25.1309. The applicant should specifically assess

what information is necessary in those conditions, and how such information

will be simultaneously displayed. The applicant should also show that

supplemental information does not displace or otherwise interfere with

required information.

Analysis as the sole means of compliance is

not sufficient for new or novel display management schemes. The applicant

should use simulation of typical operational scenarios to validate the flight

crew’s ability to manage available information.

b. Clutter

[CS 25.1302]

Clutter is the presentation of information in

a way that distracts flight-crew members from their primary task. Visual or

auditory clutter is undesirable. To reduce flight-crew member’s interpretation

time, equipment should present information simply and in a well-ordered way.

Applicants should show that an information delivery method (whether visual or

auditory) presents the information the flight-crew member actually requires to

perform the task at hand. The flight crew can use their own discretion to limit

the amount of information that needs to be presented at any point in time. For

instance, a design might allow the flight crew to program a system so that it

displays the most important information all the time, and less important

information on request. When a design allows, flight crew selection of

additional information, the basic display modes should remain uncluttered.

Automatically de-cluttering display options

can hide needed information from the flight-crew member. The applicant should show that equipment

that uses automatic de-selection of data to enhance the flight-crew member’s

performance in certain emergency conditions provides the information the

flight-crew member requires. Use of

part-time displays depends not only on information de-clutter goals but also

on display availability and criticality. Therefore, when designing such

features, the applicant should follow the guidance in AMC 25-11.

Because of the transient nature of auditory

information presentation, designers should be careful to avoid the potential

for competing auditory presentations that may conflict with each other and

hinder interpretation. Prioritisation and timing may be useful to avoid this

potential problem.

Prioritise information according to task

criticality. Lower priority information should not mask higher priority

information and higher priority information should be available, readily

detectable, easily distinguishable and usable. This does not mean that the

display format needs to change based on phase of flight.

c. System

response to control input [CS 25.1302]

Long or variable response times between

control input and system response can adversely affect system usability. The

applicant should show that response to control input, such as setting values,

displaying parameters, or moving a cursor symbol on a graphical display is

fast enough to allow the flight crew to complete the task at an acceptable

performance level. For actions requiring noticeable system processing time

equipment should indicate that system response is pending.

5.5 System Behaviour

Flight crew task demands vary depending on the characteristics of the

system design. Systems differ in their responses to relevant flight crew

input. The response can be direct and unique as in mechanical systems or it

can vary as a function of an intervening subsystem (such as hydraulics or

electrics). Some systems even automatically vary their response to capture or

maintain a desired aeroplane or system state.

As described in paragraph 5.1, CS 25.1302(c) states that installed equipment

must be designed so that the behaviour of the equipment that is operationally

relevant to the flight crew’s tasks is: (1) predictable and unambiguous, and

(2) designed to enable the flight crew to intervene in a manner appropriate to

the task (and intended function).

The requirement for operationally relevant system behaviour to be

predictable and unambiguous will enable a qualified flight crew to know what

the system is doing and why. This means that a crew should have enough

information about what the system will do under foreseeable circumstances as a

result of their action or a changing situation that they can operate the

system safely. This distinguishes system behaviour from the functional logic

within the system design, much of which the flight crew does not know or need

to know.

If flight crew intervention is part of the intended function or

non-normal procedures for the system, the crewmember may need to take some

action, or change an input to the system. The system must be designed

accordingly. The requirement for flight crew intervention capabilities

recognises this reality.

Improved technologies, which have increased safety and performance,

have also introduced the need to ensure proper cooperation between the flight

crew and the integrated, complex information and control systems. If system

behaviour is not understood or expected by the flight crew, confusion may

result.

Some automated systems involve tasks that require flight crew attention

for effective and safe performance. Examples include the flight management

system (FMS) or flight guidance systems. Alternatively, systems designed to

operate autonomously, in the sense that they require very limited or no human

interaction, are referred to as 'automatic systems'. Such systems are switched

'on' or 'off 'or run automatically and are not covered in this paragraph.

Examples include fly-by-wire systems, full authority digital engine controls

(FADEC), and yaw dampers. Detailed specific guidance for automatic systems can

be found in relevant parts of CS-25.

Service experience shows that automated system behaviour that is

excessively complex or dependent on logical states, or mode transitions are

not understood or expected by the flight crew can lead to flight crew

confusion. Design characteristics such as these have been determined to

contribute to incidents and accidents.

This sub-paragraph provides guidance material for showing compliance

with these design considerations for requirements found in CS 25.1302(c), CS 25.1301(a), CS 25.1309(c), or any other

relevant paragraphs of CS-25.

5.5.2 System

Function Allocation

The applicant should show that functions of the proposed design are

allocated so that:

—

The

flight crew can be expected to complete their allocated tasks successfully in

both normal and non-normal operational conditions, within the bounds of

acceptable workload and without requiring undue concentration or causing undue

fatigue. (See CS 25.1523 and CS-25 Appendix D for workload evaluation);

—

Flight

crew interaction with the system enables them to understand the situation, and

enables timely detection of failures and crew intervention when appropriate;

—

Task

sharing and distribution of tasks among flight-crew members and the system

during normal and non-normal operations is considered.

5.5.3 System Functional Behaviour

A system’s behaviour results from the interaction between the flight

crew and the automated system and is determined by:

—

The

system’s functions and the logic that governs its operation; and

—

The

user interface, which consists of the controls and information displays that

communicate the flight crew’s inputs to the system and provide feedback on

system behaviour to the crew.

It is important that the design reflect a consideration of both of

these together. This will avoid a design in which the functional logic

governing system behaviour can have an unacceptable effect on crew

performance. Examples of system functional logic and behaviour issues that may

be associated with errors and other difficulties for the flight crew are the

following:

—

Complexity

of the flight crew interface for both inputs (entering data) and outputs.

—

Inadequate

understanding and inaccurate expectations of system behaviour by the flight

crew following mode selections and transitions.

Inadequate understanding and incorrect expectations by the flight crew

of system intentions and behaviour.

Predictable and Unambiguous System Behaviour (CS 25.1302(c)(1))

Applicants should propose the means they will use to show that system

or system mode behaviour in the proposed design is predictable and unambiguous

to the flight crew.

System or system mode behaviour that is ambiguous or unpredictable to

the flight crew has been found to cause or contribute to flight crew errors.

It can also potentially degrade the flight crew’s ability to perform their

tasks in both normal and non-normal conditions. Certain design characteristics

have been found to minimise flight crew errors and other crew performance

problems.

The following design considerations are applicable to operationally

relevant system or system mode behaviours:

—

Simplicity

of design (for example, number of modes, mode transitions).

—

Clear

and unambiguous mode annunciation. For example, a mode engagement or arming

selection by the flight crew should result in annunciation, indication or

display feedback adequate to provide awareness of the effect of their action.

—

Accessible

and usable methods of mode arming, engagement and de-selection. For example,

the control action necessary to arm, engage, disarm or disengage a mode should

not depend on the mode that is currently armed or engaged, on the setting of

one or more other controls, or on the state or status of that or another

system.

—

Predictable

un-commanded mode change and reversions. For example, there should be

sufficient annunciation, indication or display information to provide

awareness of uncommanded changes of the engaged or armed mode of a system.

Note that formal descriptions of modes typically define them as

mutually exclusive, so that a system cannot be in more than one mode at a

particular time. For instance, a display can be in “north up” mode or “track

up” mode, but not both at the same time.

For specific guidance on flight guidance system modes, see AMC 25.1329.

Flight Crew Intervention (CS 25.1302(c)(2))

Applicants should propose the means that they will use to show that

system behaviour in the proposed design allows the flight crew to intervene in

operation of the system without compromising safety. This should include

descriptions of how they will determine that functions and conditions in which

intervention should be possible have been addressed.

If done by analysis, the completeness of the analysis may be