AMC No.2 to CS 25.1329 Flight Testing of Flight Guidance Systems

ED

Decision 2007/020/R

Some aspects

of a Flight Guidance System (FGS) design may be validated by laboratory

testing or by simulation, other aspects may necessitate test pilot expertise

and subjective judgment in a representative aircraft environment. The purpose

of this AMC is to provide FGS flight test procedures without specifying the

test means to be used, i.e. actual aircraft or representative flight

simulator.

A flight

test program should be established that confirms the performance of the FGS

for the modes of operation and the operational capabilities supported by its

design. The operational implications of certain failures and Failure

Conditions may require flight evaluation. The pilot interface with FGS

controls and displays in the cockpit should also be assessed.

The scope of

the flight demonstration program will be dependent on the operational

capability being provided including any new and novel features. Early

coordination with the regulatory authorities is recommended to reduce

certification risks associated with the flight demonstration program.

The intent

of the flight demonstration program is to confirm that the operation of the

FGS is consistent with its use for the intended flight operations of the

aeroplane type and configuration.

The modes of

the FGS should be demonstrated in representative aeroplane configurations and

under a representative range of flight conditions.

The

following are specific test procedure that can assist in that demonstration

program. The procedures should be read in conjunction with Sections 10, 11 and

14 of AMC No. 1 to CS 25.1329.

2. Protection Features

Protection

feature are included in the design of an FGS to assist the flight crew in

ensuring that boundaries of the flight envelope or operational limits are not

exceeded leading to an unsafe condition. The means to alert the flight crew to

a condition or for the system to intervene to preclude the condition may vary

but certain operational scenarios can be used to assess the performance of the

system in providing the protection function. The following procedures can be

used to evaluate the protection functions of an FGS.

The low

speed protection feature in an FGS is intended to prevent loss of speed to an

unsafe condition (Refer to AMC No. 1 to CS 25.1329 – Section 10.4.1). This may

be accomplished by a number of means but should be evaluated under a number of

scenarios.

There are

four cases that should be considered when evaluating when the Low Speed

Protection function of a FGS:

1. High Altitude Cruise Evaluation.

(a) At high altitude at normal cruise speed,

engage the FGS into an Altitude Hold mode and a Heading or LNAV mode.

(b) Engage the autothrust into a speed mode.

(c) Manually reduce one engine to idle

thrust.

(d) As the airspeed decreases, observe the FGS

behaviour in maintaining altitude and heading/course.

(e) When the Low Speed Protection condition

becomes active, note the airspeed and the associated aural and visual alerts

including possible mode change annunciations for acceptable operation.

2. Altitude Capture Evaluation at Low

Altitude.

(a) At about 1000 m (or 3000 ft) MSL and 460

km/h (or 250 kt), engage the FGS into Altitude Hold and a Heading or LNAV

mode.

(b) Engage the autothrust into a speed mode.

(c) Set the Altitude Pre-selector to 2500 m

(or 8000 ft) MSL.

(d) Make a flight level change to 2500 m (or

8000 ft) with a 460 km/h (250 kt) climb at maximum climb power.

(e) When the FGS first enters the altitude

capture mode, retard an engine to idle power.

(f) As the airspeed decreases, observe the

aeroplane trajectory and behaviour.

(g) When the Low Speed Protection condition

becomes active, note the airspeed and the associated aural and visual alerts

including possible mode change annunciations for acceptable operations.

3. High Vertical Speed Evaluation.

(a) Engage the FGS in Vertical Speed Mode with

a very high rate of climb.

(b) Set the thrust to a value that will cause

the aeroplane to decelerate at about 1.8 km per second (1 knot per second).

(c) As the airspeed decreases, observe the

aeroplane trajectory and behaviour.

(d) When the Low Speed Protection condition

becomes active, note the airspeed and the associated aural and visual alerts

including possible mode change annunciations for acceptable operation.

4. Approach Evaluation.

(a) Conduct an instrument approach with

vertical path reference.

(b) Couple the FGS to the localizer and

glideslope (or LNAV/VNAV, etc.).

(c) Cross the Final Approach Fix/Outer Marker

at a high-speed (approximately Vref + 74 km/h (40 kt)) with the thrust at idle

power until low speed protection activates.

(d) As the airspeed decreases, observe the

aeroplane trajectory and behaviour.

(e) When the Low Speed Protection condition

becomes active, note the airspeed and the associated aural and visual alerts

including possible mode change annunciation for acceptable operation.

(f) Note the pilot response to the alert and

the recovery actions taken to recover to the desired vertical path and the

re-capture to that path and the acceleration back to the desired approach

speed.

NOTE: If

the FGS remains in the existing mode with reversion to Low Speed Protection,

the FGS should provide a suitable alert to annunciate the low speed condition.

In this case, note the pilot response to the alert and the recovery actions

taken to maintain the desired vertical path and to accelerate back to the

desired approach speed.

The

high-speed protection feature in an FGS is intended to prevent a gain in

airspeed to an unsafe condition (Refer to AMC No. 1 to CS 25.1329 – Section

10.4.2). This may be accomplished by a

number of means but should be evaluated under a number of scenarios.

There are

three cases that should be considered when evaluating the High-speed

protection function of a FGS:

1. High Altitude Level Flight Evaluation

with Autothrust function

(a) Select Autothrust Off (if an automatic

wake-up function is provided; otherwise, select Autothrust on).

(b) Engage the FGS in altitude hold.

(c) Select a thrust level that will result in

acceleration beyond VMO/MMO.

(d) As the airspeed increases, observe the

behaviour of the High-speed protection condition and any autothrust

reactivation and thrust reduction, as applicable.

(e) Assess the performance of the FGS to

control the airspeed to VMO/MMO, or other appropriate speed.

2. High Altitude Level Flight Evaluation

without Autothrust function

(a) Select a thrust value that will result in

acceleration beyond VMO/MMO.

(b) As the airspeed increases, observe the

basic aeroplane overspeed warning activate between VMO + 1 and VMO + 11 km/h

(6 kt).

(c) Observe the high-speed protection

condition become active as evidenced by the unique visual alert and note

possible FGS mode change.

(d) Maintain the existing thrust level and

observe the aeroplane depart the selected altitude.

(e) After sufficient time has elapsed to

verify and record FGS behaviour has elapsed, reduce the thrust as necessary to

cause the aeroplane to begin a descent.

(f) Observe the FGS behaviour during the

descent and subsequent altitude capture at the original selected altitude.

3. High Altitude Descending Flight

Evaluation with Autothrust function

(a) Select Autothrust Off (with automatic

wake-up function) with thrust set to maintain airspeed 10% below VMO/MMO with

the FGS engaged in altitude hold.

(b) Select vertical speed mode that will

result in acceleration beyond VMO/MMO.

(c) As the airspeed increases observe the

autothrust function reactivate and reduce thrust towards idle.

(d) Observe the activation of FGS high-speed

protection condition.

(e) Observe the reduction in pitch.

GENERAL NOTE: If the FGS remains in the

existing mode with reversion to High Speed Protection, the FGS should provide

a suitable alert to annunciate the high-speed condition. In this case, note

the pilot response to the alert and the recovery actions taken to maintain the

desired vertical path and to decelerate back to the desired speed.

3. Environmental

Conditions

Some

environmental conditions have created operational problems during FGS

operations. It should be the objective of the flight demonstration program to

expose the FGS to a range of environmental conditions as the opportunity

presents itself. These include winds, windshear, mountain-wave, turbulence,

icing, etc. However, some specific test conditions may have to be created to

emulate operational conditions that are not readily achieved during normal

flight test.

The

accumulation of ice on the wing and airframe can have an effect on aeroplane

characteristics and FGS performance. FGS operations may mask the onset of an

aeroplane configuration that would present the pilot with handling

difficulties when resuming manual control, particularly following any

automatic disengagement of the FGS.

During the

flight test program the opportunity should be taken to evaluate the FGS during

natural icing conditions including the shedding of the ice, as applicable.

It is

recommended that the opportunity should be taken to evaluate the operation of

the FGS during basic aeroplane evaluation with ‘ice shapes’.

The

following conditions should be considered for evaluating FGS performance under

‘icing conditions’:

(a) "Holding ice" as defined by

CS-25 Appendix C

(b) Medium to light weight, symmetric fuel

loading

(1) High lift devices retracted configuration:

Slow down at 1.8 km per second (1

knot per second) to automatic autopilot disengage, stall warning or entry into

speed protection function.

Recovery should be initiated a

reasonable period after the onset of stall warning or other appropriate

warning. The aeroplane should exhibit no hazardous characteristics.

(2) Full Instrument Approach:

If the

autopilot has the ability to fly a coupled instrument approach and go-around,

it should demonstrate the following:

(i) Instrument approach using all normal flap

selections.

(ii) Go-around using all normal flap

selections.

(iii) Glideslope capture from above the

glidepath.

(3) If the aeroplane accretes or sheds ice

asymmetrically it should be possible to disengage the autopilot at any time

without unacceptable out of trim forces.

(4) General manoeuvrability including normal

turns, maximum angle of bank commanded by the FGS in one direction and then

rapid reversal of command reference to the maximum FGS angle of bank in the

other direction.

The test method for most Failure

Conditions will require some type a fault simulation technique with controls

that provide for controlled insertion and removal of the type of fault

identified as vulnerability. The insertion point will typically be at a major

control or guidance point on the aeroplane (e.g., control surface command,

guidance command, thrust command).

The implication of the effect of the

Failure Condition on various flight phases should be assessed and the

demonstration condition established. This assessment should identify the

parameters that need to be measured and the instrumentation required.

The role of any monitoring and

alerting in the evaluation should be identified.

The alertness of the crew to certain

aeroplane response cues may vary with phase of flight and other

considerations. Guidance on this is provided below.

The ‘success criteria’ or operational

implications should be identified and agreed with the regulatory authority

prior to the conduct of the test. Guidance on this is provided below.

4.2 Fault

Recognition and Pilot

Action

The Safety

Assessment process may identify a vulnerability to the following types of

Failure Condition:

—

hardover

—

slowover

—

oscillatory

The various

types of effect will cause differing response in the aeroplane and resultant

motion and other cues to the flight crew to alert them to the condition. The

flight crew attention may be gained by additional alerting provided by systems

on the aeroplane. The recognition is then followed by appropriate action

including recovery.

The

assessment of the acceptability of the Failure Condition and the validation of

the Safety Assessment assumptions are complete when a stable state is reached

as determined by the test pilot.

The

following paragraphs provide guidance for specific phases of flight.

This

material addresses the use of an FGS after rotation for takeoff.

Section 13

of AMC No. 1 to CS 25.1329 identifies the key considerations for this phase of

flight to be the effect on the net flight path and the speed control after

lift-off. Automatic control is not typically provided for the takeoff roll. It

may however be selected soon after lift-off. Failure Conditions may be

introduced with this engagement.

For the

initial lift-off through flap retraction, it can be assumed that the flight

crew is closely monitoring the aeroplane movements and a maximum crew response

time after recognition would be 1 second.

4.2.2 Climb,

Cruise, Descent and Holding and Manoeuvring

The

demonstration of applicable failure conditions during these phases of flight

would include the potential for occupants to be out of their seats and moving

about the cabin.

There are

two types of approach operations to consider – an approach with and without

vertical path reference. The approach with vertical path reference will be

assessed against ground-based criteria using a deviation profile assessment. A

height loss assessment is used for approaches without vertical path reference.

4.2.3.1 Fault Demonstration Process

The

worst-case malfunction has first to be determined, based on factors such as:

i) Failure Conditions identified by the

system safety assessment.

ii) System characteristics such as

variations in authority or monitor operation.

iii) Mitigation provided by any system alerts.

iv) Aircraft flight characteristics relevant

to failure recognition.

Once the

worst-case malfunction has been determined, flight tests of the worst-case

malfunction should be flown in representative conditions (e.g. coupled to an

ILS), with the malfunction being initiated at a safe height. The pilot should

not initiate recovery from the malfunction until 1 second after the

recognition point. The delay is intended to simulate the variability in

response to effectively a “hands off” condition. It is expected that the pilot

will follow through on the controls until the recovery is initiated.

4.2.3.2 Assessment – Approach with Vertical

Path Reference

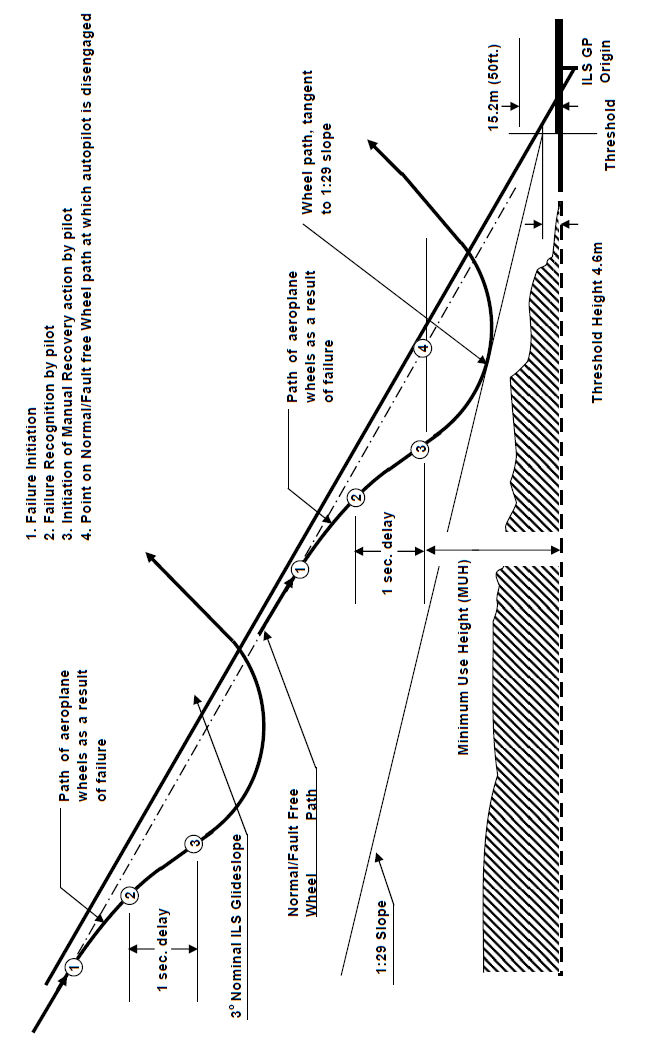

Figure 1

provides a depiction of the deviation profile method. The first step is to

identify the deviation profile from the worst-case malfunction. The next step

is to ‘slide’ the deviation profile down the glidepath, until it is tangential

to the 1:29 line or the runway. The Failure Condition contribution to the

Minimum Use Height may be determined from the geometry of the aircraft wheel

height determined by the deviation profile, relative to the 1:29 line

intersecting a point 4.5 m (15 ft) above the threshold. The method of

determination may be graphical or by calculation.

NOTE: The Minimum Use Height is based on the

recovery point because:

i) It is assumed that in service the pilot

will be “Hands off” until the autopilot is disengaged at the Minimum Use

Height in normal operation.

ii) The test technique assumes a worst case

based on the pilot being “Hands off” from the point of malfunction initiation

to the point of recovery.

iii) A failure occurring later in the approach

than the point of initiation of the worst case malfunction described above is

therefore assumed to be recovered earlier and in consequence to be less

severe.

4.2.3.3 Assessment – Approach without Vertical

Path Reference

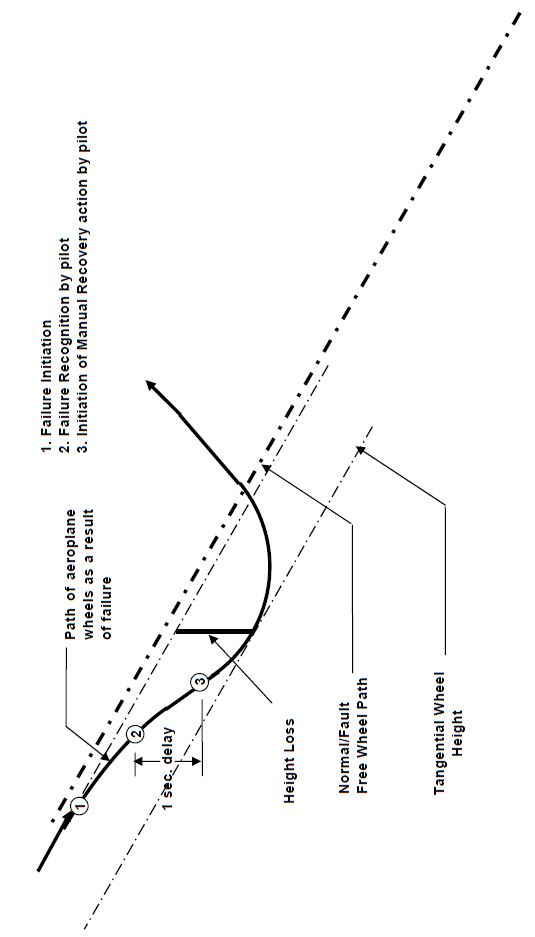

Figure 2

provides a depiction of the height loss method. A descent path of three

degrees, with nominal approach speed, should be used unless the autopilot is

to be approved for significantly steeper descents. The vertical height loss is

determined by the deviation of the aircraft wheel height relative to the

nominal wheel flight path.

Figure FT-1: Deviation Profile Method

Figure FT-2: Height Loss Method

4.3 Autopilot Override

The initial

tests to demonstrate compliance should be accomplished at an intermediate

altitude and airspeed e.g. 4500 m (15000 ft) MSL and 460 km/h (250 kt). With

the autopilot engaged in altitude hold, the pilot should apply a low force

(sustained and incremental) to the control wheel (or equivalent) and verify

that the automatic trim system does not produce motion resulting in a

hazardous condition. The pilot should then gradually increase the applied

force to the control wheel (or equivalent) until the autopilot disengages.

When the autopilot disengagement occurs, observe the transient response of the

aeroplane. Verify that the transient response is in compliance with Section

8.4 of AMC No. 1 to CS 25.1329.

Disengagement

caused by flight crew override should be verified by applying an input on the

control wheel (or equivalent) to each axis for which the FGS is designed to

disengage, i.e. the pitch and roll yoke, or the rudder pedals (if applicable). The inputs by the pilot should build up to a

point where they are sharp and forceful, so that the FGS can immediately be

disengaged for the flight crew to assume manual control of the aeroplane.

If the

autopilot is designed such that it does not automatically disengage during an

autopilot override and instead provides a flight deck Alert to mitigate any

potentially hazardous conditions, the timeliness and effectiveness of this

Alert. The pilot should follow the

evaluation procedure identified above until such time as an Alert is provided.

At that time, the pilot should respond to the Alert in a responsive manner

consistent with the level of the alert (i.e., a Caution, a Warning) and with

the appropriate flight crew procedure defined for that Alert. When the autopilot is manually disengaged,

observe the transient response of the aeroplane and verify that the transient

response is in compliance with AMC No. 1 to CS 25.1329 Section 8.4.

After the

initial tests have been successfully completed, the above tests should be

repeated at higher altitudes and airspeeds until reaching MMO at high cruise

altitudes.

[Amdt 25/4]