AMC

25.1193(e) Engine cowling and nacelle skin, APU compartment external skin

ED Decision 2013/010/R

(a) PURPOSE

This AMC provides guidance for showing compliance with the

certification specifications relating to fire withstanding capability of

engine cowlings and nacelles skins, and APU compartment external skins, in

areas subject to flame if a fire starts in an engine or APU fire zone, in

consideration of potential hazard levels associated to operating conditions

(flight/ground).

(b) RELATED CERTIFICATION SPECIFICATIONS

(c) APPLICABILITY

This AMC is applicable to engine cowlings and nacelles, and APU

compartment external skins (fixed and/or removable).

(d) BACKGROUND

CS 25.1193(e) and CS 25J1193(e) previously required the engine

cowlings/nacelle skins and APU compartment external skins to be fireproof if a

fire starts in the engine power or accessory sections or in the APU

compartment. During past Type certification projects, it has been found that

having non-fireproof engine cowlings/nacelle skins in some locations under

some operating conditions do not adversely affect safety. Consequently, in

practice, not all cowlings/skins ‘subject to flame if a fire starts in the engine

power or accessory sections’ have been required to be fireproof under all

operating conditions and, for instance, some portions were approved as

fire-resistant only for ground operating conditions. As it represented a rule

relaxation, such non-fireproof cowlings/skins were formally found to be

‘equivalently safe’ to comply with the rule. Over time, however, these

equivalent safety findings became inherent within traditionally accepted

design practices. Certification Review Item (CRI) released to cover the

relaxation included also interpretations for zone definitions and operating

conditions to be considered for fireproofness or fire-resistance compliance

demonstration.

(e) FIRE WITHSTANDING REQUIREMENTS, OPERATING CONDITIONS AND POTENTIAL

HAZARDS

(1) General

The required level of ability to withstand the effects of fire varies

with the potential hazard level associated with different flight and ground

operating conditions, as follows.

(2) Flight

Conditions

For the purpose of CS

25.1193(e) and CS 25J1193(e), flight

conditions are defined as aeroplane operation from airspeed above minimum V1

until minimum touchdown speed in approved normal or abnormal operations.

Cowling and skin in areas subject to flame if a fire starts in an engine or

APU fire zone must be demonstrated to be fireproof.

For demonstrating the fireproof capabilities of the cowling/skin, the following apply:

(i) Credit

from the external airflow on the cowling/skin can be considered.

(ii) The

airflow levels and the engine/APU powers should be consistent with the

operating conditions. These parameters should be examined and the most

critical ones should be determined.

(iii) The

engine/APU should be considered to be operative for the first 5 minutes, and

during the remaining 10 minutes under windmilling conditions for engine and stopped

conditions for the APU.

(3) Ground

conditions

For the purpose of CS

25.1193(e) and CS 25J1193(e), ground

conditions are defined as aircraft operation not covered by the flight

conditions provided in subparagraph (e)(2) of this AMC. It includes static,

taxiing, take-off roll, and landing roll.

(i) Areas

where fireproof skins are required — The portion of cowling and skin in areas

subject to flames if a fire starts in an engine or APU fire zone, and located

so that not containing the effects of the fire could result in serious hazards

to the aircraft, injuries to crew, passengers or ground personnel, must be

fireproof under all conditions. Serious hazards include, but are not limited

to, events such as fuel tank explosion, hazardous spread of fire to flammable

fluid sources outside the fire zone, fuselage penetration and flight control

surface damages.

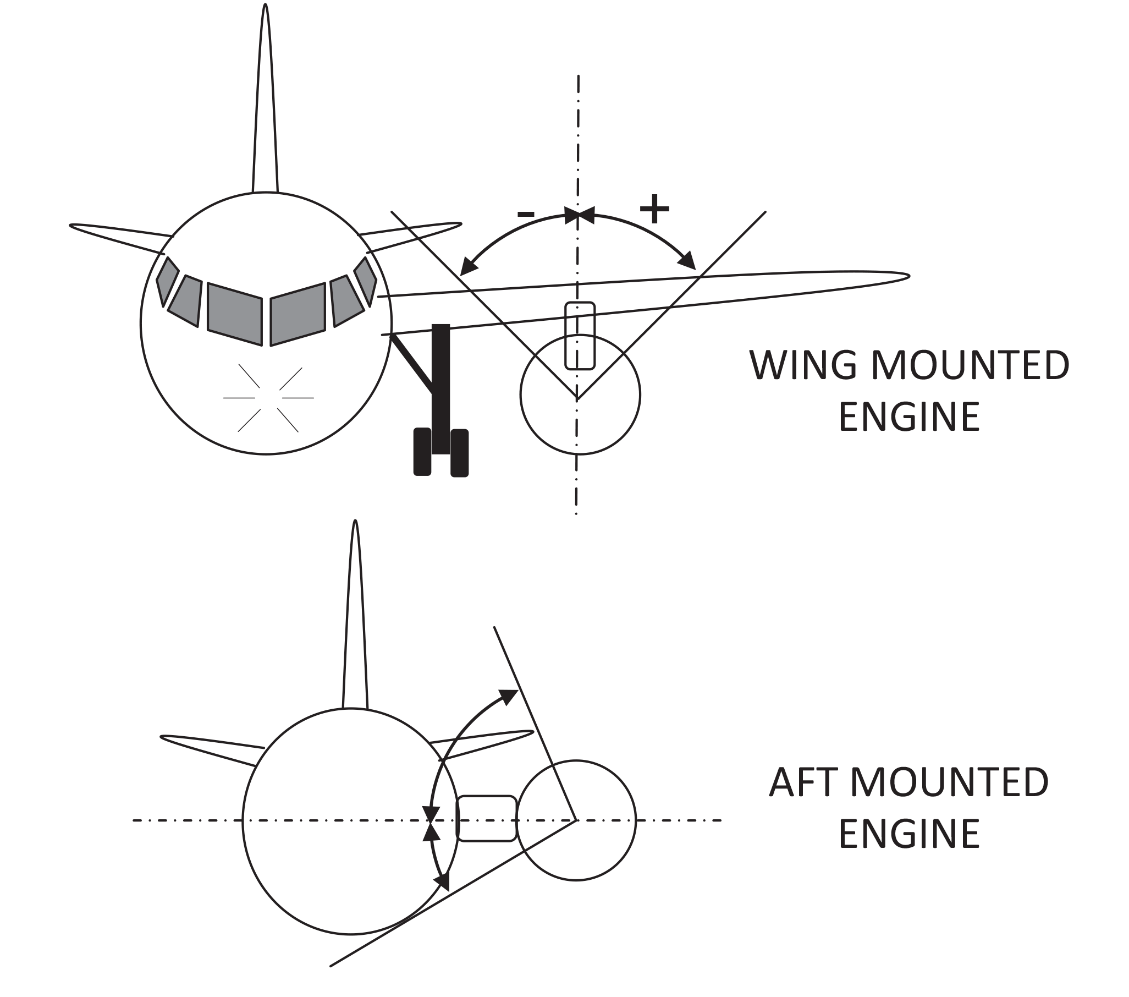

(A) Pod-mounted engines: The portion of the nacelle/cowling skin, which is required to be fireproof on ground, varies by installation. A design is considered acceptable when it is demonstrated that the fireproof area protects the pylon strut and other portions of the aircraft considered to be put at a serious hazard risk if a burn through occurs. Factors to consider within the analysis and to use when substantiating the design are: the engine location — wing or aft fuselage mounted, the coupling distance of the nacelle to the wing, the airflow characteristics, the fluid migration scheme and the fire plume patterns. After the initial analysis, similarity demonstration and in-service experience may be used as appropriate. Analyses have demonstrated that the typical area of concern ranges from 90° (± 45°) to 180° (± 90°) and is centred on the pylon centre line. This area may increase or decrease depending on the analysis results. For example, most wing mounted engines not closely coupled to the wing have been found acceptable with a ± 45° protection while more closely coupled installations and those with other unique design features have required ± 90° protection. The symmetry of the protection may also vary. Wing mounted engines usually have symmetrical protection while aft mounted engines may have non-symmetrical protection in order to cover more of the inboard area.

(B) Turbo-propellers,

APUs and other non-pod-mounted engines: Due to the wide variations in

installation configurations, each installation should be evaluated to

determine if not containing the effects of a fire would cause a serious hazard

such as the examples above. If so, the affected area of the fire zone skin

should be fireproof.

(C) For the

purpose of the demonstration:

—

No credit from external airflow on the

cowling/skin should be considered in conjunction with the assumption that the

aircraft may be static.

—

The engine/APU should be considered to be

operative for the first 5 minutes and stopped for the remaining 10 minutes.

—

Engine/APU operation — Requirements for ability of

cowling/skin in areas subject to flames if a fire starts in an engine or APU

fire zone to withstand the effects of fire in ground operating conditions

apply with either the engine operating or not operating, whichever is the more

critical. The Engine/APU operating conditions shall be justified by the

applicant.

(ii) Other areas: For the remaining portions of cowling/skin in areas subject to flames, if a fire starts in an engine or APU fire zone, the degree of fire resistance can be lower than ‘fireproof’ due to less serious or less probable hazard to the aircraft, crew, passengers and ground personnel under the critical operating conditions. Any burn through of the APU compartment external skin should consider hazards associated with combustion product and possible outgassing and re-ingestion of toxic air into cabin air system.

(A) Fire-resistant

cowlings/skins provide adequate fire protection for those areas as they

provide sufficient time to stop the aeroplane and evacuate it.

(B) A lower

than ‘fire-resistant’ degree of fire protection may be considered; the

following conditions should then be analysed and submitted to the Agency for

approval:

—

Cowling/skin should have the ability to withstand

fire at least equivalent to the ability of a 1 mm (0.040 inch) aluminium sheet

in the worst aircraft and engine/APU ground conditions anticipated;

—

Applicants must substantiate that this lower fire

protection level will not lead to hazardous effects including but not limited

to:

—

Upon burn through of the lower than

‘fire-resistant’ area, both the fire-resistant and/or fire-proof areas shall

not have their fire withstanding capability affected,

—

Liberation of parts that would affect the

aeroplane evacuation procedure or reduce the efficiency of fire protection

means,

—

Reduction in flammable fluid drainage capability

such that fire severity would be increased (magnitude, residual presence,

propagation to surrounding area),

—

Reduction in aeroplane evacuation capability due

to proximity to evacuation paths or due to the visibility of the fire

hindering the ability of the passengers to evacuate the aeroplane in a rapid

and orderly manner,

Note: There is some hazard involving aeroplane evacuation even in the

absence of burn through due to such concerns as smoke and flaming liquids

exiting from openings. Burn through of nacelle skin should not significantly

increase these hazards.

—

Reduction in fire detection capability such that

the flight crew would not be aware of the fire, especially in a situation

involving taxiing prior to take-off,

—

Reduction in fire extinguishing capability which

could cause or aggravate one of the potential hazards listed above.

—

Flammable fluid and/or fire spreading on the

aeroplane evacuation path

(f) SPECIFIC CONFIGURATION CONSIDERATIONS

(1) Multiple

skin layers: For some specific fire zones, a fire originating in that zone

will have to pass through several layers of cowling or skin before burning

through the external skin. This may be the case, for example, for the core

zone of some turbofan installations. In such cases, credit may be taken for

multiple layers, having regard to the location of the fire source and the

likely direction of propagation from that location, providing burn through of

the inner layer does not produce other

hazardous effects and it does not invalidate other certification

specifications such as fire extinguishing capability. The corresponding

compliance substantiation should take into account particular geometrical

configuration with respect to the risk of flame propagation, as well as

critical systems or structures.

(2) Inlet

skins: For external inlet skins, which enclose fire zones, the guidance

provided above for multiple skin layers applies. Inlet ducts should meet CS

25.1103/CS 25J1103 specifications.

(3) Openings:

The following considerations are applicable to openings in a fire zone skin

whether the openings are of fixed size, variable or controllable size, or

normally closed, such as access or inspection doors, or pressure relief doors.

(i) Openings

should be located such that flame exiting the opening would not enter any

other region where it could cause a hazard in flight or a serious hazard on

the ground as per subparagraph (e)(3). Exception is made for covered openings

which meet the same criteria for ability to withstand the effects of fire as

the surrounding cowl skin, and which are not expected to become open under

fire conditions. Since pressure relief doors may open during some fire

conditions, they should be located such that flames exiting the door will not

cause a hazard. However, doors that will remain closed during most fire

conditions, or will tend to re-close following initial opening, have

traditionally been assumed to be closed for the purposes of evaluating fire

detection and extinguishing.

(ii) Openings

should have the same ability to withstand the effects of fire as the adjacent

skin with respect to becoming enlarged under fire conditions. Some

enlargement, such as burning away of louvers or doublers surrounding the

opening or gapping of covered openings, is acceptable provided that the hazard

is not significantly increased by a reduction in fire extinguishing or

detection capability, increased airflow causing increase in fire size or

intensity, or increase in probability of a hazardous spread of fire to other

regions.

(4) Hinges,

Fittings and Latches: These attaching means maintaining the nacelle/cowlings

between them or to the aircraft/engine/APU structure may need to have a

greater ability to withstand the effect of fire than the surrounding skin.

Loss of attaching means may create more severe hazards such as cowling

liberation in comparison to a skin burn through. The applicant must justify

the required level of fire withstanding capability by test and/or analysis.

(5) Seals:

Where seals are used part of the external engine nacelle/cowling or APU

compartment boundaries, they should at least comply with the same fire

integrity standard as the surrounding cowling/skin.

(g) COMPLIANCE DEMONSTRATION

Compliance should be substantiated per CS 25.1207. Substantiation involving airflow patterns may include analytical methods such as Computational Fluid Dynamics, test methods or other flow visualisation methods or a combination of these methods. Fire testing should be accomplished according to the guidance of ISO 2685 with considerations of applications of representative conditions (airflow, loads, vibrations) and establishment of appropriate pass/fail criteria (burn through, elongation, dislocation).

[Amdt 25/13]