ED Decision 2015/009/R

(1) Definitions. The following are defined for the purpose of this AMC:

|

Vibration

Survey: |

A vibration survey is a test or series of tests which, either

alone or in conjunction with validated analysis, establishes the vibratory

characteristics of Engine components. |

|

Baseline Test: |

A baseline test is one which was performed for the purpose of

establishing experimentally the dynamic characteristics of Engine components

using hardware, and/or under conditions, different from those for which

approval is currently sought, and is an essential requirement for a

complementary validated analysis. |

|

Validated

Analysis: |

A validated analysis is one with demonstrated predictive

capability within a specified domain of applicability that encompasses one

or more complementary baseline tests. |

|

Module: |

A module is either a compressor or a turbine which may be single

or multi-stage, or a gear box. If multi-stage, the rotating elements are

mechanically joined and rotate at the same speed. The gas path entry and

exit points are clearly defined and are frequently nodal points in a

performance model. Note: A single stage or subset of stages isolated from a

multi-stage compressor or turbine does not constitute a module. |

|

Physical

Rotational Speed (Nr): |

The physical rotational speed of the rotating elements of a

module is the raw uncorrected rotational speed. It is rotational speed as

normally understood. The descriptor ‘physical’ is added in order to

differentiate it clearly from corrected speed. |

|

Minimum

Rotational Speed (Min Nr): |

The minimum rotational speed of the rotating elements of a

module is the lowest steady state rotational speed which can be obtained

within the limits imposed by the Engine Control System under Fault free

conditions throughout the declared flight envelope. |

|

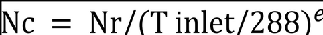

Corrected Speed

(Nc): |

The corrected speed of the rotating elements of a module is the

rotational speed normalised to a standard inlet temperature of 15°C in

accordance with the formula:

where T inlet is the module gas path inlet temperature in Kelvin

and the exponent e is determined empirically but has a typical value of 0.5.

Corrected speed is a parameter widely used in performance modelling. |

|

Declared Flight

Envelope: |

The declared flight envelope is the set of all airborne and

ground conditions of operation to be approved, including start-up, shutdown

and windmilling rotation in flight. |

|

Resonance: |

Resonance is a condition that occurs when an oscillatory force

applied to a component has a frequency that coincides with one of the

component’s natural frequencies, resulting in an elevated vibratory

response. A unique vibratory mode exists for each natural frequency. |

|

Flutter: |

Flutter is a self-excited vibration of a component in a gas

flow, caused by a continuous interaction between the gas flow and the

structure, in which energy from the flow is diverted to the structure such

that the vibratory response is sustained or increased. In turbomachinery, it

usually occurs at a natural frequency of the structure and in the associated

mode shape. |

|

Significant

Response: |

A significant response is one in which a vibratory stress

exceeds the level that has been previously agreed by the Agency as providing

acceptable margin under CS-E 70 and CS-E 100 for the type of feature

concerned. |

|

Endurance

Limit: |

The endurance limit of a component is the maximum value of

alternating stress that, when repeated for an essentially infinite number of

cycles, will not result in high cycle fatigue failure of the component. 107

cycles have generally been accepted as ‘essentially infinite’. The endurance

limit is a function of steady-state stress, temperature, geometry and

material properties. |

(2) Introduction

The intent of the rule is to ensure the acceptable dynamic behaviour of all components and assemblies in a gas turbine Engine. More specifically, the rule is aimed at the avoidance of damaging high cycle fatigue failures.

(3) Selection of Components

CS-E 650(a) requires that the survey covers all components that may be subject to mechanically or aerodynamically induced vibrations. Component selection for the survey should be based on an appropriate combination of experience, analysis, and component test. The selected components would normally include:

— the most critical blades and vanes, from a vibration point of view, in the fan and each compressor and turbine module;

— all blade rows adjacent to variable incidence vanes;

— all fan, compressor and turbine discs and spacers;

— all main rotor shaft systems (and gears, when included in such systems);

— any other component specifically identified as requiring Engine test to substantiate analysis and/or to supplement component tests.

(4) Test Conditions

A test or series of tests is an essential element of the survey. Whether the tests are new or baseline, the following conditions apply:

(a) Rig testing

Normally, a full Engine test is the preferred means to complete the survey. However, an applicant may elect to use rig tests for overcoming limitations associated with a full Engine test, such as the amount of instrumentation capable of being fitted or the range of inlet conditions that can be tested. Rig tests generally consist of testing full or part of Engine modules. If rig tests are employed, the applicant should demonstrate that all pertinent interface conditions and physical hardware closely replicate actual Engine conditions.

(b) Speed requirements

It should be the goal of the test programme to cover at least the ranges of conditions required under CS-E 650(b) and (c).

CS-E 650(b)(1) requires consideration of 103 % of the maximum rotational speed permitted for rating periods of two minutes or longer, but where it proves physically impracticable to achieve the appropriate extended test conditions, the Agency may accept an alternative that complies with the intent of the requirement. Historically, the 3 % margin has been imposed to account for transient overshoot. If it can be demonstrated that the characteristics of the Engine Control System are such that the maximum rated speed cannot be exceeded in fault-free operation, the required maximum tested speed may, with the agreement of the Agency, be adjusted downward, but may not be less than 100 %.

Where an extension to the range required by CS-E 650(b) is considered necessary for the identification of the effects of a rising vibratory stress peak, as required under CS-E 650(c), but it proves physically impracticable to achieve the appropriate extended test conditions, the Agency may accept an alternative that complies with the intent of the requirement. Historically, the requirement has been imposed to account for Engine-to-Engine variability. The Engine manufacturing and build tolerances can result in peak vibratory stresses occurring at slightly different rotor speeds for Engines and Engine parts (for example blades) of the same type design. If tested components are deliberately selected to cover an adverse range of manufacturing variability or any other effect normally captured by increasing the test maximum speed by a further 2 %, the required maximum tested speed may, with the agreement of the Agency, be adjusted downward, but may not be less than the maximum speed established for compliance with CS-E 650(b).

Any reduction in the speed range requirements of CS-E 650(b) and (c) proposed for the test programme should be justified by the applicant and agreed by the Agency. Normally, it would be expected that any test shortfall is covered by validated analysis.

Refer also to paragraph (5) ‘Altitude and Temperature Effects’ and (8) ‘Flutter’ for complementary guidance on affecting speeds.

(c) Instrumentation

To acquire the data required under CS-E 650 when conducting vibration surveys, the applicant should use suitable instrumentation, data acquisition, and analyser systems. Vibration-specific instrumentation may include dynamic strain gauges, accelerometers, dynamic pressure gauges and time-of-arrival sensors.

Vibratory stresses are most commonly calculated using dynamic strain gauges placed at predetermined locations and oriented to measure specific directional strains. These strain gauges should maintain their accuracy throughout the test conditions, particularly when repeatedly exposed to high temperatures for extended periods. The applicant should aim to take measurements at locations which are sensitive to the peak responses of interest but are also tolerant of a degree of mislocation/alignment variability. When these locations are not suitable or accessible for that purpose, stresses may be measured nearby provided that the relationships between the stresses at these locations and those at critical locations are known and predictable. To identify the accessible locations that best represent the critical stresses, knowledge of each natural mode and associated stress distributions is required, which may be gained from a combination of experience, analyses, or testing. This investigation is usually conducted before the certification test.

Time-of-arrival sensors, such as optical sensors or light probes, may prove convenient alternatives to strain gauges provided they are properly calibrated and their capabilities are clearly understood. The most common application for time-of-arrival sensors is to estimate blade tip displacements, which may then be converted to stresses at specific blade locations. Converting measured displacements or gauge strains to vibratory stresses requires a detailed knowledge of the blade normal mode frequencies, mode shapes, modal stress/strain distributions and associated tip displacements. This conversion should be shown to be sufficiently accurate or at least conservative. Time-of-arrival data for vibratory modes where measured displacements have low sensitivity in relation to stresses in critical areas should not be used in order to avoid excessive uncertainty in endurance limit calculations.

(d) Instrumentation survivability

Where the Engine operates at such high rotor speeds and gas path temperatures that test instrumentation can only survive the environment for short periods of time, validated analysis would be expected to complete the substantiation. The loss of instrumentation should be minimal and the associated analysis should be primarily based on the surviving instrumentation data.

(e) Engine modifications

During testing, the Engine may be modified or adjusted in an effort to achieve the desired physical and corrected speeds, or any other test conditions. Any alterations made to the Engine for these purposes should be evaluated to show that their effects are not detrimental or do not compromise the intent of the test and the test results.

(5) Altitude and Temperature Effects

CS-E 650(a) requires that conditions throughout the declared flight envelope are evaluated when establishing that the dynamic behaviour of components and systems is acceptable.

Changes in operating conditions associated with ambient temperature and altitude variations affect Engine performance and airflow characteristics. This can have a significant effect on aerodynamic forcing and damping, which, in turn, affects the vibratory response and behaviour of certain components. Appropriate justification should be provided by the applicant that the worst operating conditions in the declared flight envelope have been fully explored.

Engine tests may be conducted by means of flight test or in altitude facilities or in other facilities such that the effects of altitude and temperature are properly represented and can be evaluated. Suitable test equipment and instrumentation should be used for each situation. The dependency of certain vibratory phenomena on temperature and altitude can be characterised as a dependency on corrected speed, which enables such phenomena to be investigated by means of sea-level testing, provided that the entire required corrected speed range can be achieved. In general, a high corrected speed implies that the airflow over the blading has a high Mach number, which is associated with higher aerodynamic forcing and lower aerodynamic stability.

(6) Fault Conditions

A number of common Fault conditions can have the effect of introducing additional excitation sources or changes to those existing under Fault-free conditions. Any change in vibration response should be evaluated and shown not to result in a Hazardous Engine Effect.

CS-E 650(g) applies to those Fault conditions that would cause abnormal vibrations that are difficult to identify in a timely manner so that appropriate mitigating action can be taken. Notwithstanding the provisions of CS-E 60 and CS-E 510 with regard to instrumentation, certain low-level vibrations caused by Fault conditions may not be recognised as associated with an Engine Fault and may not prompt an immediate response. Subsequently, these Faults may escalate to Hazardous Engine Effects. For example, the loss of an airfoil tip would be likely to result in a change in vibration due to the increased out-of-balance. Even if indicated by the means required under CS-E 60 and CS-E 510, this vibration might not be immediately recognised as abnormal or may not prompt immediate action, and could cause further damage. Other Faults include incorrectly scheduled compressor variables, stator vanes blockages or enlargement, and blockages of fuel nozzles. These Faults could produce local airflow distortions and changes in the airflow or pressure distributions that in turn may affect component vibratory response and characteristics. To address these Fault conditions, the applicant may use prior experience with Faults that occurred on other similar Engines. Successful experience is such that, after exposure to a Fault condition, the Engine was able either to continue in safe operation or to be shut down without creating a Hazardous Engine Effect. Applicants may also use field experience or other means to show that certain Fault conditions are Extremely Remote because of specific Engine configurations, design features or operating conditions. The requirements of CS-E 650(g) apply to the same components that are considered under CS-E 650(a). When the effects of these Fault conditions extend to the rest of the Engine, they must be addressed under the requirements of CS-E 100 Strength and/or CS E 520 Strength (for example, the out-of-balance effects on the Engine structural components).

(7) Inlet Airflow Distortion

Fan and compressor vibration can be sensitive to inlet airflow distortion, and conditions consistent with the most adverse pattern declared by the applicant should be taken into account. Inlet airflow distortion may be associated with the air intake, crosswinds, or other operating and aircraft installation conditions. When an Engine test is performed, whether in a test cell or on a flight test bed, the inlet distortion may be achieved by various means, such as external crosswind devices, inlet distortion plates or suppression screens.

(8) Flutter

Testing required to demonstrate satisfactory vibratory clearance from flutter boundaries may be accomplished by rig and/or Engine sea-level or altitude test, subject to the following considerations:

(a) The presence of flutter may be acceptable in some circumstances, for example in a speed range encountered only briefly or infrequently, or where the flutter amplitude is limited to a safe level. However, the resulting vibration stresses must always satisfy the requirements of CS-E 650(f). A thorough investigation of the flutter response and its effects should be completed to show that the flutter does not result in a Hazardous Engine Effect. The investigation may include testing as required under paragraph (10) below for a significant response.

(b) In all cases, the test procedure needs to recognise that some systems’ susceptibilities to flutter will not be revealed during tests if the relevant operating conditions are not sustained long enough for the flutter to develop.

(c) As flutter is a phenomenon which can be sensitive to small variations in those factors which could influence the response of the system, due consideration should also be given to possible variations between the nominal and extreme values of, for example, tip clearances, mechanical damping, operating lines and bleed flows. Experience has also shown that there are differences in susceptibility to flutter from one blade set to another and that ‘tuned’ blade sets might be more sensitive.

(d) If tests will be conducted at sea level only, the applicant should propose a procedure acceptable to the Agency to account for altitude effects. For certain Engine modules, especially fans and compressors, it is expected that this will be achieved by testing throughout the range of corrected speed that the module will encounter in service, in which case the requirements of CS-E 650(b) and (c) with regard to physical rotational speed should be considered to apply also to corrected speed. The provisions of paragraph (4)(b) of this AMC are also applicable.

(e) For some turbines, the propensity to flutter is not increased at maximum corrected speed, and other methods of demonstrating the absence of damaging flutter throughout the declared flight envelope may be more appropriate. It is important to ensure that the maximum stage inlet pressure at each physical speed is achieved, or compensation is provided. The strength of aerodynamic forcing on many turbine blades is predominantly driven by the total pressure levels, and the highest pressures are expected at the highest mechanical speed. Where turbines operate in aerodynamically choked conditions and the mass flow through the turbine is dictated by the fixed geometry of the blading, the corrected speed is essentially constant. Higher corrected speed (at an aerodynamic work level) will lower the blading Mach numbers (Mn) and, conversely, a lower corrected speed will increase blading Mn. This means that, in such cases, running up to 100 % of maximum mechanical speed will cover the worst case (highest forcing) condition.

(f) In general, the methods used to verify the absence of damaging levels of flutter throughout the declared flight envelope should include consideration of applicable combinations of the following:

(i) the ranges of physical and corrected rotational speeds for each rotor module;

(ii) the simultaneous occurrence of maximum fan or compressor inlet air total temperature and maximum corrected rotational speed (i.e. maximum reduced velocity);

(iii) the range of fan or compressor operating lines within the flight envelope;

(iv) the most adverse of other fan or compressor inlet air conditions encountered within the flight envelope (e.g. applicable combinations of total air pressure, density, temperature, and inlet distortion); and

(v) the hardware standard, the intake conditions and margins to account for Engine deterioration.

(9) Variations in Material Properties and Natural Frequencies

Allowance should be made as follows for the permitted variations in material properties, critical dimensions and resulting natural frequencies of production components when interpreting test results or making analytical predictions:

(a) Material allowable stresses

The material property that is important in relation to the requirements of CS-E 650(f) is the endurance limit associated with specific combinations of mean stress and alternating stress, usually represented on a Goodman diagram. The influence on the endurance limit of manufacturing processes, the local geometrical features, and temperatures should also be taken into account.

(b) Stress margins

Section CS-E 650(f) requires suitable stress margins for each part evaluated, usually represented by the stress margins at the critical or limiting locations. The stress margin is the difference between the material allowable at a particular location and the measured vibratory stress at that location. The criteria for stress margin suitability should account for the variability in design, operation and other mitigating factors identified during the certification test.

(c) Modal response

The total vibratory stress at any given location is the sum of the resonant stresses associated with all active and concurrent normal modes, plus any other vibratory stresses that occur at that particular rotational speed. Due to variability in properties (material and geometry) the frequencies and separation of the modes may be different from blade to blade (or other component). The applicant should consider the stress amplitudes that occur within permitted blade-to-blade variations of natural frequency. For example, if for a particular blade design the natural frequency (fn) range is fn ± 2.5 %, then the combined amplitudes within this range should be considered.

Where there is potential for more than one mode to be excited at the same time/speed, the overall amplitude will be a combination of contributions from each individual response. The combined stress is typically calculated by breaking down the vibratory stress of each mode into its stress components and then combining the modal contributions in proportion to the individual measured responses to obtain the overall principal or equivalent vibratory stresses.

(10) Dwell Testing

The applicant should determine all significant responses within the operating conditions prescribed in CS-E 650 and allow sufficient time for any associated resonant modes to respond. This is usually accomplished during slow acceleration and deceleration speed sweeps covering the range of required speeds.

If any significant response is found, then the relevant components should be subjected to sufficient cycles of vibration close to, and/or on, the response peak to demonstrate compliance with CS-E 650(f). This dwell testing would normally be incorporated into the incremental periods of the CS-E 740 Endurance Test as required by CS-E 740(g)(1).Components subjected to such dwell testing should subsequently also meet the strip inspection requirements of CS-E 740(h).

(11) Transient Response

Consideration should also be given to the speed range from zero to minimum rotational speed, especially in the case of supercritical shafts. Some predicted potentially damaging transient responses may require an aggressive control input to provoke a representative response.

(12) Instrumentation Incompatibility

If the dimensions of the components to be tested are incompatible with the necessary instrumentation, instrumented Engine tests to substantiate the vibration characteristics of these components and the variation of the Endurance Test incremental running as prescribed in CS-E 740(g)(1) may be waived wholly or in part if the Agency is satisfied that the total hours of operation accumulated on test beds or in flight, under representative conditions, prior to certification are sufficient to demonstrate that the vibration stress levels are acceptable.

(13) Installation Compatibility

The intent of CS-E 650(h) is to ensure vibratory compatibility between the Engine and each intended installation configuration when the Engine is installed and operated in accordance with the manufacturer’s approved instructions. The applicant will normally be expected to provide sufficient information in the Engine instructions for installation to enable the aircraft manufacturer(s) to establish that the installation does not unacceptably affect the Engine’s vibration characteristics. In establishing vibratory compatibility between the Engine and the installation, consideration should be given to the need to declare operating limitations and procedures. Where appropriate, at least the following aspects and installation features should be considered:

— each Propeller approved for use on the Engine;

— each thrust reverser approved for use on the Engine;

— installation influences on inlet and exhaust conditions;

— mount stiffness; and

— rotor drive systems.

(14) Modelling and Analysis

Acceptable analytical methods are based on the complementary concepts of a baseline test and validated analysis. The general principle is that a baseline test in conjunction with validated analysis is equivalent to a new test.

(a) Baseline test

A baseline test is usually one of the following:

(i) An Engine or rig test run on the first model of an Engine type during the type certification programme. The validated analysis developed on the basis of this test may then be used for derivative models that are added to the same type certificate.

(ii) An Engine or rig test run on a previously certified Engine type. The validated analysis developed on the basis of this test may then be used for Engines whose design characteristics and operating conditions are shown to be sufficiently similar to those of the Engine in the baseline test.

(iii) An Engine or rig test specifically run to support the creation of the validated analysis.

The design characteristics and operating conditions run in the baseline test(s) should be shown to be sufficiently similar and inclusive of the domain of applicability for the Engine being certified, as defined in this AMC, paragraph (14)(b)(i), (ii) and (iii).

A test from which the results are used to calibrate an analysis is not in general eligible to be considered a baseline test in relation to the validation of that analysis. The same test results cannot be used both to calibrate and validate an analysis.

(b) Validated Analysis

(i) Development of the Validated Analysis.

The analytical model should be validated against one or more baseline tests.

For each baseline test on which the validation is based, it should be shown that the analysis consistently predicts the observed behaviour and vibratory responses of the components investigated to an acceptable precision and accuracy. Alternatively, it could be shown that predictions reliably overpredict the vibratory response.

The applicant should clearly define the domain of applicability of the analysis, comprising the ranges of design characteristics and operating conditions for which the analysis will be deemed to be validated. Typical design characteristics and operating conditions which may constitute a definition of the domain of applicability are as follows:

— Engine architecture:

— general configuration, for example 2- or 3-shaft design, turboshaft, turbofan, open rotor, geared fan;

— secondary air system;

— number, location and type of bearings, including installation (inner/outer race grounded, inter-shaft, damped, etc.), and associated support structures.

— Module type, for example high or low pressure turbine, axial or radial compressor.

— Component geometry, for example shrouded or unshrouded blades, aerofoil aerodynamic shapes (‘2D’ or ‘3D’).

— Structural dynamic characteristics:

— natural frequencies, which will influence the resonance speeds and aerodynamic stability (flutter);

— mode shape similarity, for example a measure of accuracy that is often employed is the Modal Assurance Criterion (MAC). Typically, a MAC value greater than 0.9 indicates there is close agreement between measured and calculated mode shapes. Close matching of mode shapes implies that response to the same forcing will be similar;

— mechanical damping levels; any difference will be directly reflected in the resonant response level or flutter suppression;

— mistuning levels; the degree of scatter in frequency between blades will strongly influence the vibration amplitudes variability in a bladed disc and will have a stabilising influence on flutter.

— All structural dynamic characteristics affected by:

— materials and construction technique, for example composites, anisotropic metals, joining methods

— restraints, for example blade or vane attachment design, snubbers or dampers, flanges.

Similarity of the structural dynamic characteristics is frequently demonstrated by a combination of comparative analysis and modal testing in a laboratory.

— Aeroelastic characteristics:

— The Strouhal number (k) or reduced frequency which characterises the variation of flow with time, where k = ω.c/U, ω = frequency, c = component length in flow direction and U = flow velocity, is relevant for flutter.

— Sources of vibratory excitations and forcing strength:

— upstream or downstream rotors, stators or struts, for example numbers off, aerodynamic style, axial gapping;

— gas stream characteristics, inlet or flow path asymmetry, main gas path and secondary flows;

— power or thrust levels, air density, Mach number and Reynolds number that can affect both flutter and forced response amplitudes,

— combustion system

— mechanical sources, for example gearbox and rotor out-of-balance.

— Operating conditions:

— rotational speeds, temperatures and gas pressures experienced by the subject components throughout the declared flight envelope.

The validated analysis and its domain of applicability should be acceptable to the Agency.

(ii) Use of the Validated Analysis

Similarity of the Engine, module or component(s) to be certified with previously tested and certified designs should be justified. For each new Engine certification programme, for which the use of validated analysis is proposed, the applicant should show that the design characteristics and operating conditions of the Engine fall within the domain of applicability of the analysis previously established and accepted by the Agency.

The demonstration of compliance will be considered to be the combination of the baseline test(s) used to create the validated analysis, and the analysis performed on the Engine for which approval is currently sought.

Examples where validated analysis may be used include but are not limited to the following:

— Where test speeds required by CS-E 650(b) and (c) are not achieved, by agreement with the Agency as described in paragraph (4)(b) of this AMC. The validated analysis would be expected to cover the speed range(s) or operating conditions not achieved during testing.

— Where instrumentation has been lost, for example due to the extreme test conditions. The validated analysis would be expected to cover the speed range(s) or operating conditions for which instrumentation was lost.

— Where stresses are not measured directly at critical locations. In that case, the peak stresses may be derived based on measurements taken at reference locations. This requires a detailed understanding of the modal composition of the response and the associated mode shapes to derive the relationship between each location.

— Where it proves necessary to justify the acceptability of any significant responses whether observed or predicted.

(iii) Update of the Validated Analysis

It is expected that the applicant may regularly update the validated analysis, for instance following new testing performed or service experience. The updated validated analysis and/or its domain of applicability should be reviewed and accepted by the Agency.

(15) Inspection Specifications

The pre-certification activity necessary for determining which Engine components require verification by Engine test and also for determining the proper location of Engine test instrumentation will typically include substantive tests and analyses for determining component (or system) natural frequencies, mode shapes, steady-state mean stress and vibratory stress distributions. These development activities will generate engineering data essential to supporting the certification test and should be exempt from formal Agency approval of test plans and reports. Inspection of type design hardware in accordance with the requirements of 21.A.33 of Part-21 should be limited to only those pertinent Engine components and associated instrumentation that constitute the certification Engine test or the baseline tests supporting the validated analysis.

[Amdt. No.: E/1]

[Amdt. No. E/4]