AMC 25-19 Certification Maintenance Requirements

ED

Decision 2018/005/R

1 PURPOSE

This

Acceptable Means of Compliance (AMC) provides guidance on the selection,

documentation and control of Certification Maintenance Requirements (CMRs).

This AMC also provides a rational basis for coordinating the CMR selection

process and the Maintenance Review Board (MRB) process if the latter is used.

The applicant should ensure that the maintenance tasks and intervals

identified in the system safety analyses to support compliance with CS 25.1309

and other system safety requirements (such as CS 25.671, CS 25.783, CS 25.901,

and CS 25.933) are protected in service. For those

aeroplanes whose initial maintenance programme is developed under a different

process than the MRB process, the coordination and document aspects have to be

adapted to the particular case. This AMC describes an acceptable means, but

not the only means, for selecting, documenting and managing CMRs. Terms such

as ‘shall’ and ‘must’ are used only in the sense of ensuring applicability of

this acceptable means of compliance.

2 RELATED CERTIFICATION

SPECIFICATIONS

a. CS 25.671 Control Systems — General

b. CS 25.783 Fuselage Doors

c. CS 25.901 Powerplant — Installation

d. CS 25.933 Reversing systems

e. CS 25.1309 Equipment, systems and installations

f. CS 25.1529 Instructions for Continued Airworthiness

3 RELATED DOCUMENTS

a. Airlines for America (A4A), MSG–3,

Operator/Manufacturer Scheduled Maintenance Development Document.

b. International Maintenance Review

Board/Maintenance Type Board Process Standard (IMPS)

4 NOT USED

5 CERTIFICATION MAINTENANCE REQUIREMENTS (CMR) DEFINITION

A CMR is a

required scheduled maintenance task, established during the design

certification of the aeroplane systems as an airworthiness limitation of the

type certificate (TC) or supplemental type certificate (STC). The CMRs are a

subset of the Instructions for Continued Airworthiness (ICA) identified during

the certification process. A CMR usually result from a formal, numerical

analysis conducted to show compliance with the requirements applicable to

catastrophic and hazardous failure conditions as defined in paragraph 6e,

below. A CMR may also result from a qualitative, engineering judgment-based

analysis.

a. The CMRs are required tasks, and

associated intervals, developed to achieve compliance with CS 25.1309

and other requirements requiring safety analyses (such as CS 25.671, 25.783, 25.901, and

25.933). A

CMR is usually intended to detect latent failures that would, in combination

with one or more other specific failures or events, result in a Hazardous or

Catastrophic Failure Condition. A CMR can also be used to establish a required

task to detect an impending wear out of an item whose failure is associated

with a hazardous or catastrophic failure condition. A CMR may also be used to

detect a latent failure that would, in combination with one specific failure

or event, result in a major failure condition, where the SSA identifies the

need for a scheduled maintenance task.

b. CMRs are derived from a fundamentally

different analysis process than the maintenance tasks and intervals that

result from MSG–3 analysis associated with MRB activities (if the MRB process

is used). Although both types of analysis may produce equivalent maintenance

tasks and intervals, it is not always appropriate to address a Candidate

Certification Maintenance Requirement (CCMR) with a Maintenance Review Board

Report (MRBR) task.

c. CMRs verify that a certain failure has

or has not occurred, indicate that corrective maintenance or repair is

necessary if the item has failed, or identify the need to inspect for

impending failures (e.g. wear out or leakage). Because the exposure time to a

latent failure is a key element in the calculations used in a safety analysis,

limiting the exposure time will have a significant effect on the resultant

overall failure probability of the system. The intervals for CMR tasks

interval should be designated in terms of flight hours, cycles, or calendar

time, as appropriate.

d. The type certification process assumes

that the aeroplane will be maintained in a condition or airworthiness equal to

its certified condition. The process described in this AMC is not intended to

establish routine maintenance tasks (e.g. greasing, fluid-level checks, etc.)

that should be defined through the MSG–3 analysis process. Also, this process

is not intended to establish CMRs for the purpose of providing supplemental

margins of safety for concerns arising late in the type design approval

process. Such concerns should be resolved by appropriate means, which are unlikely

to include CMRs not established via normal safety analyses.

e. CMRs should not be confused with

required structural inspection programmes, that are developed by the TC applicant

to meet the inspection requirements for damage tolerance, as required by CS 25.571 or CS 25.1529, and Appendix H25.4

(Airworthiness Limitations Section). CMRs are to be developed and managed

separately from any structural inspection programs.

6 OTHER DEFINITIONS

The

following terms apply to the system design and analysis requirements of CS

25.1309(b) and (c), and to the guidance material provided in this AMC. (for a

complete definition of these terms, refer to the applicable specifications and

acceptable means of compliance, (e.g. CS and AMC 25.1309)).

a. Catastrophic. Refer to AMC 25.1309.

b. Compatible MRBR task. An MRBR task whose

intent addresses the CCMR task intent and whose interval is equal to or lower

than the interval that would otherwise be required by a CMR.

c. Crew. The cabin crew, or flight crew, as

applicable.

d. Failure. Refer to AMC 25.1309.

e. Failure Condition. Refer to AMC 25.1309.

f. Failure Effect Category 5 task (FEC5).

Refer to MSG-3, Operator/Manufacturer Scheduled Maintenance Development.

g. Failure Effect Category 8 task (FEC8).

Refer to MSG-3, Operator/Manufacturer Scheduled Maintenance Development.

h. Hazardous. Refer to AMC 25.1309.

i. Latent Failure. Refer to AMC 25.1309.

j. Major. Refer to AMC 25.1309.

k. Qualitative. Refer to AMC 25.1309.

l. Quantitative. Refer to AMC 25.1309.

m. Significant Latent Failure. A latent

failure that would, in combination with one or more other specific failures or

events, result in a hazardous or catastrophic failure condition.

n. Task. Short description (e.g. descriptive

title) of what is to be accomplished by a procedure. Example: ‘Operational

check of the static inverter’.

o. Wear out. A condition where a component

is worn beyond a predetermined limit.

7 SYSTEM SAFETY

ASSESSMENTS (SSA)

a. CS 25.1309(b) specifies required safety levels

in qualitative terms, and a safety assessment must be conducted to show

compliance. Various assessment techniques have been developed to help

applicants and EASA in determining that a logical and acceptable inverse relationship

exists between the probability and the severity of each Failure Condition.

These techniques include the use of service experience data of similar,

previously approved systems, and thorough qualitative and quantitative

analyses.

b. In addition, difficulties have been

experienced in assessing the acceptability of some designs, especially those

of systems, or parts of systems, that are complex, that have a high degree of

integration, that use new technology, or that perform safety-critical

functions. These difficulties led to the selective use of rational analyses to

estimate quantitative probabilities, and the development of related criteria

based on historical data of accidents and hazardous incidents caused or

contributed to by failures. These criteria, expressed as numerical probability

ranges associated with the terms used in CS 25.1309(b), became commonly

accepted for evaluating the quantitative analyses that are often used in such

cases to support experienced engineering and operational judgement and to

supplement qualitative analyses and tests.

NOTE: See

AMC 25.1309 for a complete description of the inverse relationship between the

probability and severity of Failure Conditions, and the various methods of

showing compliance with CS 25.1309.

8 DESIGN CONSIDERATIONS

RELATED TO SIGNIFICANT LATENT FAILURES

a. The applicant should implement practical

and reliable failure monitoring and flight crew indication systems to detect

failures that would otherwise be significant latent failures. A reliable

failure monitoring and flight crew indication system should utilise current

state-of-the-art technology to minimise the probability of falsely detecting

and indicating non-existent failures. Experience and judgement should be

applied when determining whether or not a failure monitoring and flight crew

indication system would be practical and reliable. Comparison with similar,

previously approved systems is sometimes helpful.

b. Supplemental design considerations are

provided in Appendix 1 to this AMC.

9 OVERVIEW OF THE CERTIFICATION

MAINTENANCE REQUIREMENTS DEVELOPMENT PROCESS

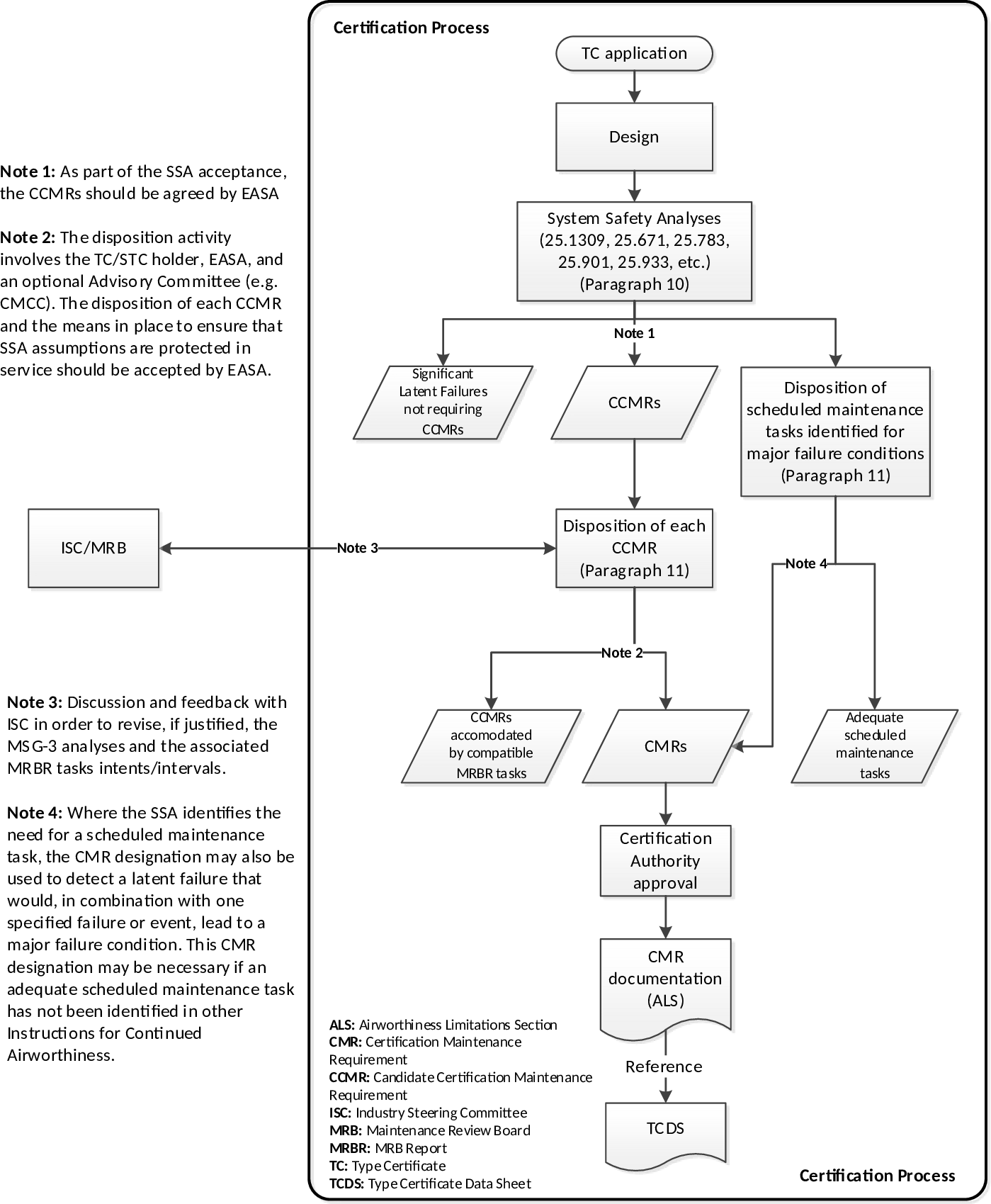

a. Figure 1 shows the development process

of CMRs. The details of the process to be followed in defining, documenting,

and handling CMRs are given in paragraphs 10 through 13.

Figure 1 — CMR development process

10 IDENTIFICATION OF CANDIDATE CMRs (CCMRs)

a. The SSA should address all significant

latent failures.

b. Credit may be taken for correct flight

crew performance of the periodic checks required to demonstrate compliance

with CS 25.1309(b). Unless these flight crew actions are

accepted as normal airmanship, they should be included in the approved

Aeroplane Flight Manual procedures. Similarly, credit may be taken from

self-initiated checks (e.g. power-up built-in tests). In both cases, these

significant latent failures do not need a CCMR.

c. Tasks that are candidates for selection

as CMRs come from safety analyses (e.g. SSAs), which establish whether there

is a need for tasks to be carried out periodically to comply with

CS 25.1309, and other requirements (such as CS 25.671, CS 25.783, CS 25.901,

and CS 25.933) requiring this type of analysis. The SSA

should identify as CCMRs the maintenance tasks intended to detect significant

latent failures. Tasks may also be selected from those intended to inspect for

impending failures due to wear out.

d. As the safety analysis may be qualitative

or quantitative, some task intervals may be derived in a qualitative manner

(e.g. engineering judgment and service experience). As per AMC 25.1309,

numerical analysis supplements, but does not replace, qualitative engineering

and operational judgment. Therefore, other tasks that are not derived from

numerical analysis of significant latent failures, but are based on properly

justified engineering judgment, can also be candidates for CMRs. The

justification should include the logic leading to identification of CCMRs, and

the data and experience base supporting the logic.

e. In some situations, a Catastrophic or

Hazardous Failure Condition might meet the quantitative probability objective,

yet it might contain one or more components that, as per the quantitative

analysis, do not require a periodic maintenance task to meet that

objective (i.e. could be failed latent for the life of the aeroplane). In such

cases, the SSA should include a qualitative assessment to determine whether a

periodic maintenance task is needed.

Unless otherwise substantiated, a CCMR

should be identified to:

—

reduce

exposure to a single failure or event that would cause the failure condition,

—

ensure

the availability of backup or emergency systems, and

—

ensure

the availability of equipment/systems required to be installed as per CS-25.

f. For failure conditions involving

multiple significant latent failures, the SSA should identify a CCMR for each

significant latent failure unless otherwise justified (e.g. one CCMR may cover

multiple significant latent failures, or the significant latent failure could

exist for the life of the aeroplane without compromising compliance with the

safety objectives and paragraph 10.e considerations).

g. For each identified CCMR, the applicant

should indicate:

—

the

failure mode to be detected,

—

the

failure condition of concern,

—

the

intended maintenance task, and

—

the

task interval (the allowable value coming from the SSA or other relevant

analysis).

11 SELECTION OF CMRs

a. Each CCMR should be reviewed and a

determination made as to whether or not it should be a CMR.

Criteria and guidance are

provided below for CMR selection or non-selection. The applicant may seek

additional input from an advisory committee, as described in Appendix 2,

before proposing CMRs to EASA for final review and approval.

b. The applicant should provide sufficient

information to enable an understanding of the Failure Conditions and the

failure or event combinations that result in the CCMRs. CCMRs are evaluated in

the context of the Failure Conditions in which they are involved, e.g. whether

the significant latent failure is part of a dual failure, a triple failure, or

more.

c. The CMR designation should be applied in

the case of catastrophic dual failures where one failure is latent. The CMR

designation should also be applied to tasks that address wear out of a

component involved in a Catastrophic Failure Condition that results from two

failures.

d. In all other cases, the CMR designation

may not be necessary if there is a compatible MRBR task to accommodate the

CCMR, provided that the applicant has the means in place to ensure that the

CCMRs are protected in service. Appendix 3 provides examples of acceptable

means of protection. Any means should be presented to EASA for acceptance.

These means

of protection should address future evolutions of the compatible MRBR task

proposed by the applicant or by the operator. In this respect, these means

should ensure that in service:

—

the

compatible MRBR task would not be changed to the extent that the CCMR task

intent is adversely affected, and

—

the

compatible MRBR task would not be escalated beyond the interval that would

otherwise be required by a CMR.

The TC

applicant should adequately describe the selected means of protection in the

associated technical publication in order for the operator to be aware of the

process to be followed if there are modifications to any compatible MRBR tasks

that are included in the operator’s aeroplane maintenance program (AMP).

e. The rationale for the disposition of each

CCMR should be presented to EASA for acceptance.

f. Since the MSG-3 logic may not consider a

Failure Condition containing three or more failures, it is possible that a

CCMR might not have any identified MRBR tasks. In this case, a CMR will be

required.

g. Where the SSA identifies the need for a

scheduled maintenance task, the CMR designation may also be used to detect a

latent failure that would, in combination with one specified failure or event,

lead to a Major Failure Condition. This CMR designation may be necessary if no

adequate scheduled maintenance task has been identified in any other

Instructions for Continued Airworthiness.

h. If the SSA does not specify an interval

shorter than the life of the aeroplane, an interval may be established by

considering the factors that influence the outcome of the Failure Condition,

such as the nature of the fault, the system(s) affected, field experience, or

task characteristics.

12 DOCUMENTATION AND

HANDLING OF CMRs

a. CMRs are considered functionally equal to

airworthiness limitations, therefore they should be included in the

Airworthiness Limitations Section of the Instructions for Continued

Airworthiness.

b. The CMR data location should be

referenced in the type certificate data sheet (TCDS). The latest version of

the applicant’s CMR documentation should be controlled by a log of pages

approved by EASA. In this way, changes to CMRs following certification will

not require an amendment to the TCDS.

c. Since CMRs are based on statistical

averages and reliability rates, an ‘exceptional short-term extension’ for CMR

intervals may be made on one aeroplane for a specific period of time without

jeopardising safety. Any exceptional short-term extensions to CMR intervals

must be defined and fully explained in the applicant’s CMR documentation. The

competent authority must concur with any exceptional short-term extension

allowed by the applicant’s CMR documentation before it takes place, using

procedures established with the competent authority in the operators’ manuals.

The exceptional short-term extension process is applicable to CMR intervals.

It should not be confused with the operator’s ‘short-term escalation’ program

for normal maintenance tasks described in the operators’ manuals.

(1) The term ‘exceptional short-term

extension’ is defined as an increase in a CMR interval that may be needed to

cover an uncontrollable or unexpected situation. Any allowable increase must

be defined either as a percent of the normal interval, or a stated number of

flight hours, flight cycles, or calendar days. If no exceptional short-term

extension is to be allowed for a given CMR, this restriction should be stated

in the applicant’s CMR documentation.

(2) Repeated use of exceptional short-term

extensions, either on the same aeroplane or on similar aeroplanes in an

operator’s fleet, should not be used as a substitute for good management

practices. Exceptional short-term extensions must not be used for the systematic

escalation of CMR intervals.

(3) The applicant’s CMR documentation should

state that the competent authority must approve, prior to its use, any desired

exceptional short-term extension not explicitly listed in the CMR document.

13 POST-CERTIFICATION

CHANGES TO CMRs (New, revised or deleted)

a. The introduction of a new CMR or any

change to an existing CMR should be reviewed by the same entities that were

involved in the process of CCMR/CMR determination (refer to paragraphs 10 and

11 of this AMC) at the time of initial certification. To allow operators to

manage their own maintenance programs, it is important that they be afforded

the same opportunity for participation that they were afforded during the

initial certification of the aeroplane.

b. Any post-certification changes to CMRs

must be approved by EASA which approved the type design.

c. Since the purpose of a CMR is to limit

the time of exposure to a given significant latent failure, or a given wear

out, as part of an engineering analysis of the overall system safety,

instances of a CMR task repeatedly finding that no failure has occurred may

not be sufficient justification for deleting the task or increasing the time

between repetitive performances of the CMR task. In general, a CMR task change

or interval escalation should only be made if experience with the aeroplane

fleet in service worldwide indicates that certain assumptions regarding

component failure rates made early during the engineering analysis were too

conservative, and a re-calculation of the system’s reliability with revised

failure rates of certain components reveals that the task or interval may be

changed.

d. If later data provides a sufficient

basis for the relaxation of a CMR (less restrictive actions to be performed),

the change may be documented by a revision to the applicant’s CMR

documentation and approved by EASA.

e. To address an unsafe condition, EASA may

determine that the requirements of an existing CMR must be modified (more

restrictive actions to be required) or a new CMR must be created. These

modified requirements will be mandated by an Airworthiness Directive (AD) and

the applicant’s CMR documentation will be revised to include the change.

f. New CMRs that are unrelated to

in-service occurrences may be created and they should be documented and

approved by EASA. New CMRs can arise in situations such as:

(1) the certification of design changes, or

(2) updates of the applicant’s certification

compliance documentation. These may result from regulatory changes, actions

required by an AD on similar systems or aeroplanes, awareness of additional

Hazardous or Catastrophic Failure Conditions, revised failure rates,

consideration of extended service goals, etc.

APPENDIX 1 SUPPLEMENTAL GUIDANCE FOR THE USE OF CMRs

1. The TC/STC applicant should choose a

system design that minimises the number of significant latent failures, with

the ultimate goal that no such failures should exist, if this is practical. A

practical and reliable failure monitoring and flight crew indication system

should be considered as the first means to detect a significant latent

failure. If the cost of adding practical and reliable failure monitoring and

flight crew indication system is high, and the added maintenance cost of a CMR

is low, the addition of a CMR may be the solution of choice for both the type

certificate applicant and the operator, provided all applicable regulations

are met. Substituting a CMR with an MRBR task does not necessarily reduce

maintenance costs.

2. The decision to create a CMR may include

a trade-off of the cost, weight, or complexity of providing mechanism or

device that will expose the latent failure, versus the requirement for the

operator to conduct a maintenance or inspection task at fixed intervals.

3. The following points should be

considered in any decision to create a CMR in lieu of a design change.

a. What is the magnitude of the changes to

the system and/or aeroplane needed to add a reliable failure monitoring and

flight crew indication system that would expose the latent failure? What is

the cost in added system complexity?

b. Is it possible to introduce a self-test

on power-up?

c. Is the monitoring and flight crew

indication system reliable? False warnings must be considered, as well as a

lack of warnings.

d. Does the failure monitoring or flight

crew indication system itself need a CMR due to its latent failure potential?

e. Is the CMR task reasonable, considering

all aspects of the failure condition that the task is intended to address?

f. How long (or short) is the CMR task

interval?

g. Is the proposed CMR task labour

intensive or time consuming? Can it be done without having to ‘gain access’

and/or without workstands? Without test equipment? Can the CMR task be done

without removing equipment from the aeroplane? Without having to re-adjust

equipment? Without leak checks and/or engine runs?

h. Can a simple visual inspection be used

instead of a complex one? Can a simple operational check suffice in lieu of a

formal functional check against measured requirements?

i. Is there ‘added value’ to the proposed

task (i.e. will the proposed task do more harm than good if the aeroplane must

be continually inspected)?

j. Have all alternatives been evaluated?

APPENDIX 2 ROLE OF THE CERTIFICATION MAINTENANCE COORDINATION COMMITTEE

(CMCC)

1. The CMCC functions as an advisory

committee for the applicant and proposes the disposition of each presented

CCMR. EASA is the authority that ultimately approves CMRs as airworthiness

limitations of the type certificate as per Part-21.

2. In order to grant aeroplane operators

the opportunity to participate in the selection of CMRs, and to assess the

CCMRs and the proposed MRBR tasks and intervals in an integrated process, the

applicant should convene a CMCC as early as possible in the design phase of

the aeroplane program, and at intervals as necessary. This CMCC should

comprise TC/STC holder representatives (typically maintenance, design, and

safety engineering personnel), operator representatives designated by the

Industry Steering Committee (ISC) chairperson, EASA certification

specialist(s), and the MRB chairperson(s). EASA certification specialist

participation in the CMCC is necessary to provide regulatory guidance on the

disposition of CCMRs.

3. The CMCC should review CCMRs and their

purposes, the Failure Conditions and their classifications, the intended tasks

and their intervals, and other relevant factors. In addition, where multiple

tasks result from a quantitative analysis, it may be possible to extend a

given interval at the expense of one or more other intervals, in order to

optimise the required maintenance activity. However, once a decision is made

to create a CMR, then the CMR interval should be based solely on the results

of the SSA or other relevant analysis. If the SSA does not specify an interval

shorter than the life of the aeroplane, then the CMR interval may be proposed

by the CMCC considering factors that influence the outcome of the failure

condition, such as the failure mode(s) to be detected, the system(s) affected,

field experience, or task characteristics.

4. The CMCC should address all CCMRs.

Alternatively, the applicant may coordinate with EASA to define a subset of

CCMRs to be presented to the CMCC.

5. The CMCC discusses compatible tasks (if

any) that the MRB generates. The CMCC may select an MRBR task in lieu of a CMR

in accordance with paragraph 11 of this AMC.

6. The CMCC may request the ISC to review

selected CMCC results (e.g. proposed revised MRBR tasks and/or intervals).

Upon ISC review, the proposed revised MRBR tasks and/or intervals accepted by

the ISC are reflected in the MRBR proposal, and the proposed revised MRBR

tasks and/or intervals rejected by the ISC result in CMRs. Following

consideration by the ISC, the applicant submits the CMRs to EASA for final

review and approval.

APPENDIX 3 MEANS OF PROTECTION PROPOSED BY THE DESIGN APPROVAL HOLDER

(DAH) AGAINST FUTURE EVOLUTIONS OF THE COMPATIBLE MRBR TASKS AND DERIVED TASKS

OF THE OPERATOR’S AEROPLANE MAINTENANCE PROGRAM — EXAMPLES

1. With reference to paragraph 11.c of this

AMC, this Appendix provides examples to facilitate the implementation of the

means to ensure that the CCMRs are protected in service.

2. These examples describe acceptable means,

but not the only means. Any means should be presented to EASA for acceptance.

EXAMPLE 1 — Traceability of CCMRs and MRBR tasks in the Airworthiness

Limitations Section

a. The CMR designation may not be necessary

if there is a compatible MRBR task to accommodate the CCMR, provided that the

design approval holder (DAH) shows direct traceability between the MRBR task

and the accommodated CCMR in the airworthiness limitations section (ALS).

b. The compatible MRBR task and its interval

are not airworthiness limitations. The status of the compatible MRBR task with

regard to the MRB process remains unchanged.

c. Traceability between the CCMR and the

compatible MRBR task should be provided in the ALS of the instructions for

continued airworthiness to ensure that the CCMR is respected during in-service

operation of the aeroplane and any future evolution of the maintenance

program.

Table 1

illustrates one possible means for traceability.

|

CCMR task reference |

CCMR interval |

Compatible MRBR task reference |

|

CCMR task #NN |

60 months |

MRBR task #XX |

|

CCMR task #MM |

10 000 flight hours |

MRBR task #YY |

|

… |

… |

… |

Appendix 3 — Table 1

d. If

the DAH changes the compatible MRBR task to the extent that the intent of the

corresponding CCMR task is adversely affected, this corresponding CCMR task is

no longer accommodated. Therefore, the DAH could either propose a new

compatible MRBR task, if one exists, or create a new CMR in line with the

intent of the previously referenced CCMR limitation. These changes to the ALS

require EASA approval.

e. If the DAH escalates the interval of the

compatible MRBR task beyond the corresponding CCMR limitation, this

corresponding CCMR is no longer accommodated and the DAH needs to create a CMR

in order to satisfy the corresponding CCMR limitation. Alternatively, the DAH

could assess the feasibility of escalating the interval of the corresponding

CCMR by re‑evaluating the system safety assumptions that lead to the CCMR at

the time of initial certification. These changes to the ALS require EASA

approval.

f. Furthermore, the DAH shall describe in

the ALS what the operator needs to observe when changing the operator’s

aeroplane maintenance program (AMP). For tasks included in an AMP, which are

based on compatible MRBR tasks, the following applies:

i. Should the operator propose to change

the intent of a task, the operator should ask for the DAH’s confirmation that

this change does not adversely affect the intent of the corresponding CCMR

task. If the corresponding CCMR task is no longer accommodated, the operator

needs to propose to include a mandatory task in the AMP in order to satisfy

the intent of the referenced CCMR limitation. These changes to the AMP require

the approval of the competent authority responsible for the oversight of the

operator.

ii. If the operator proposes to escalate the

interval of a task, the corresponding CCMR limitation must not be exceeded.

EXAMPLE 2 — Uniquely identifying the compatible MRBR tasks

a. The CMR designation may not be necessary

if there is a compatible MRBR task to accommodate the CCMR, provided that the

DAH uniquely identified each compatible MRBR task in the existing MRBR task

listing. Table 2 illustrates one possible means for marking.

|

MRBR task

reference |

MRBR task

description |

Failure effect category

(FEC) |

Interval |

Tracking |

|

MRBR task #XX |

Functional check of […] |

FEC 8 |

60 months |

|

|

MRBR task #YY |

Detailed inspection of […] |

- |

72 months |

EWIS |

|

MRBR task #ZZ |

Operational check of […] |

FEC 8 |

10 000 flight hours |

CCMR |

|

… |

… |

… |

… |

… |

Appendix 3 — Table 2

b. The purpose of the marking and the

policies to be observed for appropriate change control of the marked MRBR

tasks should be stated in the MRB report.

c. The status of the compatible MRBR task

with regard to the MRB process remains unchanged.

d. If the DAH changes the marked MRBR task

to the extent that the intent of the corresponding CCMR task is adversely

affected, the DAH needs to create a CMR to satisfy the intent of the initial

CCMR task. This change to the ALS requires EASA approval.

e. For future escalations of MRBR tasks, the

DAH should have procedures in place to ensure that these escalations do not

increase the interval of the marked MRBR task beyond the corresponding CCMR

interval.

f. However, should the DAH escalate the

marked MRBR task beyond the CCMR interval, the DAH needs to create a CMR in

order to satisfy the corresponding CCMR. This change to the ALS requires EASA

approval. Alternatively, the DAH could assess the feasibility of escalation of

the interval of the corresponding CCMR by re-evaluating the system safety

assumptions that lead to the CCMR at the time of initial certification. This

change to the CCMR interval requires EASA involvement in accordance with the

process described in paragraph 11 of this AMC.

g. Furthermore, the DAH shall describe in

the MRBR what the operator needs to observe when changing the operator’s

aeroplane maintenance program (AMP). For tasks included in the AMP, which are

based on marked MRBR tasks, the following applies:

i. If the operator proposes to change the

intent of a task, the operator should ask for the DAH’s confirmation that this

change does not adversely affect the intent of the corresponding CCMR task.

ii. If the operator proposes to escalate the

interval of a task, the operator should ask for the DAH’s confirmation that

this escalation does not increase the interval beyond the corresponding CCMR

interval. These changes to the AMP require the approval of the competent

authority responsible for the oversight of the operator.

[Amdt

25/20]

[Amdt

25/21]