AMC

25.571 Damage tolerance and fatigue evaluation of structure

ED Decision 2017/017/R

1. PURPOSE

This AMC provides guidance for compliance with the provisions of CS 25.571 pertaining to the damage tolerance and fatigue evaluation requirements for aeroplane metallic and non-metallic structure. It also provides rational guidelines for the evaluation of scatter factors for the determination of life limits for parts categorised as safe-life. Additional guidance material for certification of non-metallic structures that must also comply with CS 25.571 is contained in AMC 20‑29.

2. (RESERVED)

3. REFERENCES

CS 25.571 Damage tolerance and fatigue evaluation of structure,

CS 25.1529 Instructions for Continued Airworthiness,

AMC 20-20 Continued Structural Integrity Programme,

AMC 20-29 Composite Structure.

4. DEFINITIONS OF TERMS USED IN THIS AMC

‘Damage tolerance’ is the attribute of the structure that permits it to retain its required residual strength without detrimental structural deformation for a period of use after the structure has sustained a given level of fatigue, environmental, accidental, or discrete source damage.

‘Fatigue critical structure (FCS)’ is structure that is susceptible to fatigue cracking that could lead to a catastrophic failure of an aircraft.

‘Safe-life’ of a structure is that number of events such as flights, landings, or flight hours, during which there is a low probability that the strength will degrade below its design ultimate value due to fatigue cracking.

‘Design service goal (DSG)’ is the period of time (in flight cycles or flight hours, or both) established at design and/or certification during which the aircraft structure is reasonably free from significant cracking.

‘Principal structure element (PSE)’ is an element that contributes significantly to the carrying of flight, ground, or pressurisation loads, and whose integrity is essential in maintaining the overall structural integrity of the aeroplane.

‘Detail design point (DDP)’ is an area of structure that contributes to the susceptibility of the structure to fatigue cracking or degradation such that the structure cannot maintain its load carrying capability, which could lead to a catastrophic failure.

In ‘single load path structure’ the applied loads are carried through a single structural member, the failure of which would result in the loss of the structural capability to carry the applied loads.

In ‘multiple load path structure’ the applied loads are distributed through redundant structural members so that the failure of a single structural member does not result in the loss of structural capability to carry the applied loads.

‘Widespread fatigue damage (WFD)’ in a structure is characterised by the simultaneous presence of cracks at multiple structural details that are of sufficient size and density whereby the structure will no longer meet the residual strength requirement of CS 25.571(b).

(1) ‘Multiple site damage (MSD)’ is a source of widespread fatigue damage characterised by the simultaneous presence of fatigue cracks in the same structural element.

(2) ‘Multiple element damage (MED)’ is a source of widespread fatigue damage characterised by the simultaneous presence of fatigue cracks in adjacent structural elements.

(3) ‘Structural modification point (SMP)’ is the point in time when a structural area must be modified to preclude WFD.

(4) ‘Inspection start point (ISP)’ is the point in time when special inspections of the fleet are initiated due to a specific probability of having an MSD/MED condition.

‘Scatter factor’ is a life reduction factor used in the interpretation of fatigue analysis and fatigue test results.

‘Limit of validity’ (LOV) of the engineering data that supports the structural maintenance programme is not more than the period of time, stated as a number of total accumulated flight cycles or flight hours or both, during which it is demonstrated by test evidence, analysis and, if available, service experience and teardown inspection results of high-time aeroplanes, that widespread fatigue damage will not occur in the aeroplane structure

‘Normal maintenance’ is understood to be those scheduled maintenance checks during minor or base maintenance inputs requiring general visual inspections and is normally associated with a zonal programme. The zonal programme is a collective term comprising selected general visual inspections and visual checks that are applied to each zone, defined by access and area, to check system and power plant installations and structure for security and general condition. A general visual inspection is a visual examination of an interior or exterior area, installation, or assembly to detect obvious damage, failure, or irregularity. This level of inspection is made from within touching distance unless otherwise specified. A mirror may be necessary to enhance visual access to all exposed surfaces in the inspection area. This level of inspection is made under normally available lighting conditions such as daylight, hangar lighting, flashlight, or droplight and may require removal or opening of access panels or doors. Stands, ladders, or platforms may be required to gain access.

‘Teardown inspection’ is the process of disassembling structure and using destructive inspection techniques or visual (magnified glass and dye penetrant) or other, and non-destructive inspection methods (eddy current, ultrasonic) to identify the extent of damage, within a structure, caused by fatigue, environmental and accidental damage.

‘Fail-safe’ is the attribute of the structure that permits it to retain its required residual strength for a period of unrepaired use after the failure or partial failure of a principal structural element.

‘WFD(average behaviour)’ is the point in time when, without intervention, 50 % of the fleet is expected to develop WFD for a particular structure.

‘Level 1 corrosion’ is:

damage occurring between successive inspections that is within allowable damage limits; or

damage occurring between successive inspections that does not require structural reinforcement, replacement or new damage tolerance based inspections; or

corrosion occurring between successive inspections that exceeds allowable limits but can be attributed to an event not typical of operator usage of other aircraft in the same fleet; or

light corrosion occurring repeatedly between inspections that eventually requires structural reinforcement, replacement, or new damage-tolerance-based inspections.

5. BACKGROUND

(a) Since the early 1970s, there have been significant state-of-the-art and industry-practice developments in the area of structural fatigue and fail-safe strength evaluation of transport category aeroplanes. Recognising that these developments could warrant some revision of the existing fatigue requirements of § 25.571 and 25.573 of 14 CFR Part 25, the Federal Aviation Administration (FAA), on 18 November 1976 (41 FR 50956), gave notice of the Transport Category Aeroplane Fatigue Regulatory Review Programme and invited interested persons to submit proposals to amend those requirements. The proposals and related discussions formed the basis for the revision of the structural fatigue evaluation standards of § 25.571 and § 25.573 of 14 CFR Part 25 and the development of guidance material. To that end, § 25.571 was revised, § 25.573 was deleted (the scope of § 25.571 was expanded to cover the substance of the deleted section), and guidance material (FAA AC 25.571-1) was provided which contained compliance provisions related to the proposed changes.

(b) Since the issuance of FAA AC 25.571-1 on 28 September 1978, additional guidance material, including information regarding discrete source damage, was developed and incorporated in revision 1A on 5 March 1986. The AC was further revised on 18.2.1997 (revision 1B) to add guidance on the elements to be considered in developing safe-life scatter factors for certification. Although FAR, JAR, and CS 25.571 have, since 1978, required consideration of fatigue damage originating at multiple sites, the FAA AC was further revised on 29 April 1998 (revision 1C) to add guidance material whose objective was to preclude widespread fatigue damage (resulting from MSD or MED) from occurring within the design service goal of the aeroplane, and to aid in the determination of thresholds for fatigue inspection and/or other special fleet actions. JAR/CS 25.571 were not harmonised with the 1998 amendment of 14 CFR 25.571. Under the auspices of the Aviation Rulemaking Advisory Committee (ARAC), the General Structure Harmonization Working Group (GSHWG) drafted NPA 25C-292 proposing the Limit of Validity (LOV), greater emphasis on testing, corrosion and manufacturing, and accidental damage in the 25.571 requirements and corresponding AC material to support this. EASA AMC 20-20 ‘Continuing Structural Integrity Programme’ introduced the LOV-concept in 2007. AC 25.571-1D, issued on 13 January 2011, provides guidance in support of 14 CFR 25 Amdt 132 which introduced the LOV requirement. Thus, AMC 25.571 has been revised to provide guidance for establishing an LOV for the structural maintenance programme as will now be required by CS 25.571. In conclusion, this AMC revision based on the GSHWG work and recently developed FAA guidance, now better harmonises with the EASA guidance, AC 25.571-1D, and industry practice.

6. INTRODUCTION

(a) General

The content of this AMC is considered by EASA in determining compliance with the requirements of CS 25.571. The objective is to prevent catastrophic structural failures caused by fatigue damage (FD) (including e.g. widespread fatigue damage (WFD)), environmental deterioration (ED) (e.g. corrosion damage), or accidental damage (AD).

Compliance involves good design practice to ensure that damage tolerance can be achieved and the establishment of maintenance actions developed in compliance with CS 25.1529. Taken together, they result in a structure where the combination of design characteristics and maintenance actions will serve to preclude any failure due to FD, ED, or AD.

CS 25.571(a)(3) requires the applicant to establish inspections or other procedures (herein also referred to as maintenance actions) as necessary to avoid catastrophic failure during the operational life of the aeroplane based on the results of the prescribed fatigue and damage tolerance evaluations.

CS 25.571(a)(5) requires development of inspections for ED and AD. CS 25.571(b) requires the applicant to establish an LOV. Furthermore, CS 25.571(b) and (c) require establishment of inspections and replacement times respectively based on the damage tolerance and fatigue characteristics of the structure. The LOV is, in effect, the operational life of the aeroplane consistent with the evaluations accomplished and maintenance actions established to prevent WFD. The LOV is established based on WFD considerations and it is intended that all maintenance actions required to address fatigue damage, environmental deterioration (e.g. corrosion damage for metallics, moisture for composites), and accidental damage (e.g. impact, lightning), up to the LOV, are identified in the structural maintenance programme. All inspections and other procedures (e.g. modification times, replacement times) that are necessary to prevent a catastrophic failure due to fatigue, up to the LOV, must be included in the Airworthiness Limitations Section (ALS) of the Instructions for Continued Airworthiness (ICA), as required by CS 25.1529, along with the LOV.

CS 25.571(d) requires the structure to be designed such that sonic fatigue cracking is not probable or, if it arises, it will not result in a catastrophic failure. CS 25.571(e) requires the structure to be designed to withstand damage caused by specified threats such that the flight during which the damage is sustained can be completed.

(1) CS 25.571(a)(5) — Environmental and accidental damage inspections and associated procedures

Inspections for ED and AD must be defined. Special consideration should be given to those areas where past service experience indicates a particular susceptibility to attack by the environment or vulnerability to impact and/or abuse. It is intended that these inspections will be effective in discovering ED or AD before it interacts with fatigue related phenomena, and that the ED or AD will, therefore, be removed/repaired before it presents a significant risk. Typically these inspections are largely defined based on past service experience using a qualitative or quantitative process in combination with the Airline Transportation Association (ATA) Maintenance Steering Group (MSG)-3 process. For new structure and materials, testing may be required to evaluate likely AD and the subsequent tolerance of the design to it. For ED prevention, an effective CPCP is necessary, which will contain tasks and procedures in addition to inspections that will help prevent initiation and, when necessary, the recurrence of corrosion (see AMC 20-20). Furthermore, CS 25.571 requires that the ALS must include a statement that requires the operator to include a CPCP in their maintenance programme that will control the corrosion to Level 1 or better.

Any special inspections required for AD and ED, i.e. ones in addition to those that would be generated through the use of the MSG-3 process for AD and ED, or the baseline CPCP development, and which are necessary to prevent catastrophic failure of the aeroplane, must be included in the ALS of the ICA required by CS 25.1529. If a location is prone to accidental or environmental damage and the only means for detection is one that relies on the subsequent development of a fatigue crack from the original damage, then that inspection must be placed in the ALS of the ICA.

Note: The AD and ED inspection programme including the baseline CPCP are equally applicable to structures showing compliance with CS 25.571(b) and (c) respectively.

(2) CS 25.571(b) and (c) — Fatigue damage inspections or replacement times

Inspections for fatigue damage or replacement times must be established as necessary. These actions must be based on quantitative evaluations of the fatigue characteristics of the structure. In general, analysis and testing will be required to generate the information needed. The applicant should perform crack growth and residual strength testing to produce the design data needed to support crack growth and residual strength analyses. Full-scale fatigue test evidence is required to support the evaluation of structure that is susceptible to WFD. Test evidence is needed to support analysis used to establish safe-life replacement times.

(i) Inspection or replacement

Compliance with CS 25.571(b) is required unless it can be demonstrated to the satisfaction of the authority that compliance cannot be shown due to practical constraints. Under these circumstances, compliance with CS 25.571(c) is required. The only common example of structure where compliance with the requirements of CS 25.571(c), in lieu of CS 25.571(b), might be accepted, would be the landing gear and its local attachments.

(ii) ALS of the ICA

All inspections and replacement times necessary to detect or preclude fatigue cracking scenarios, before they become critical, must be included in the ALS of the ICA required by CS 25.1529.

(iii) Limit of Validity (LOV)

An LOV for the structural maintenance programme must also be determined and included in the ALS of the ICA. See section 11 of this AMC for additional guidance on the LOV.

(b) Typical loading spectrum expected in service

The loading spectrum should be based on measured statistical data of the type derived from government and industry load history studies, and where insufficient data are available on a conservative estimate of the anticipated use of the aeroplane. The development of the loading spectrum includes the definition of the expected flight plan, which involves ground manoeuvres, climb, cruise, descent, flight times, operating speeds, weights and altitudes, and the approximate time to be spent in each of the operating regimes. The principal loads that should be considered in establishing a loading spectrum are flight loads (gust and manoeuvre), ground loads (taxiing, landing impact, turning, engine run-up, braking, thrust reversing and towing), and pressurisation loads. Operations for crew training and other pertinent factors, such as the dynamic stress characteristics of any flexible structure excited by turbulence or buffeting, should also be considered. For pressurised cabins, the loading spectrum should include the repeated application of the normal operating differential pressure and the superimposed effects of flight loads and aerodynamic pressures.

(c) Areas to be evaluated

When assessing the possibility of serious fatigue failures, the design should be examined to determine probable points of failure in service. In this examination consideration should be given, as necessary, to the results of stress analyses, static tests, fatigue tests, strain gauge surveys, tests of similar structural configurations, and service experience. Service experience has shown that special attention should be focused on the design details of important discontinuities, main attach fittings, tension joints, splices, and cut-outs such as windows, doors, and other openings. Locations prone to accidental damage (such as that due to the impact with ground servicing equipment near aeroplane doors) or to corrosion should be identified for analysis.

(d) Analyses and tests

Fatigue and damage tolerance analyses should be conducted unless it is determined that the normal operating stresses are of such a low order that crack initiation and, where applicable, significant damage growth is extremely improbable. Any method used in the analyses should be supported by test or service experience. Typical (average) values of fatigue respectively fracture mechanics material properties may be used in fatigue analysis respectively residual strength and crack growth analyses. The effects of environment on these properties should be accounted for if significant.

Generally, testing will also be necessary to support compliance with CS 25.571(b) or (c). The nature and extent of testing of complete structures or portions will depend on applicable previous design and structural tests and service experience with similar structures. Structural areas such as attachment fittings, major joints, changes in section, cut-outs, and discontinuities almost always require some level of testing in addition to analysis. When less than the complete structure is tested, care should be taken to ensure that the internal loads and boundary conditions are valid. When tests are conducted to support the identification of areas susceptible to fatigue, the duration of the test should take into account factors such as material and loading spectrum variability, together with the expected operational life. Refer to Appendix 2 for specific guidance regarding testing required to establish the LOV.

(e) Discrete source damage

It must be shown that the aeroplane is capable of successfully completing a flight during which specified incidents occur and result in immediately obvious damage. The maximum extent of the damage must be quantified and the structure must be shown to be capable of sustaining the maximum load (considered as ultimate) expected during the completion of the flight. There are no maintenance actions that result from this evaluation.

7. DAMAGE TOLERANCE EVALUATION

(a) General

The damage tolerance requirements of CS 25.571(b) are intended to ensure that, should fatigue, corrosion, or accidental damage occur within the LOV, the structure will be capable of withstanding the loading conditions specified in CS 25.571(b)(1) through (b)(6) without failure or detrimental structural deformation until the damage is detected. The evaluation should include identifying the PSEs, defining the loading conditions and conducting sufficiently representative structural tests or analyses, or both, to provide sufficient data for the establishment of the inspection programme. Although this process applies to either single or multiple load path structure, the use of multiple load path structures should be given priority in achieving a damage-tolerant design. The principle analytical tool used for metallic materials to perform a damage tolerance evaluation is based on fracture mechanics. A discussion of this approach is presented in Appendix 1 of this guidance material. The means of establishing the LOV and maintenance actions specifically associated to WFD is addressed in detail in Section 11 of this AMC.

(b) Damage-tolerant characteristics

A damage-tolerant structure has two notable attributes:

(1) The structure can tolerate a significant amount of damage, due to fatigue, environmental or accidental deterioration without compromising the continued airworthiness of the aeroplane (residual strength and rigidity).

(2) The structure can sustain that damage long enough to be found and repaired during scheduled or unscheduled maintenance (inspectability).

(c) Design considerations

To achieve a damage-tolerant structure, criteria should be established to guide the design process so that this design objective is achieved. The design process should include a damage tolerance evaluation (test and analysis) to demonstrate that the damage-tolerant design objectives are achieved, and to identify inspections or other procedures necessary to prevent catastrophic failure. Reliance on special inspections should be minimised by designing structure with easily detectable (e.g. visual) cracking modes. Since the occurrence of WFD can complicate a damage-tolerant evaluation to the point that reliable inspections programmes cannot be developed even with extremely intensive inspection methods, it must be demonstrated, with sufficient full-scale fatigue test evidence, that adequate maintenance procedures are contained in the ALS of the ICA, such that WFD will not occur within the LOV. A discussion on several issues that an applicant might face in demonstrating freedom from WFD is contained in Appendix 2 to this AMC.

(d) Design features

Design features which should be considered in attaining a damage-tolerant structure include the following:

(1) multiple load path construction and/or the use of damage containment features to arrest fast fracture or reduce the crack growth rate, and to provide adequate residual strength;

(2) materials and stress levels that provide a slow rate of crack propagation combined with high residual strength; and

(3) arrangement of design details to ensure a sufficiently high probability that a failure in any critical structural element will be detected before the strength has been reduced below the level necessary to withstand the loading conditions specified in CS 25.571(b).

(e) Probabilistic evaluations

No guidance is provided in this AMC on probabilistic evaluation. Normally, damage tolerance assessments consist of a deterministic evaluation of design features described in paragraphs 7(d)(1), (2) and (3). Paragraphs (f) to (i) below provide guidelines for this approach.

(f) PSEs, detail design points, and locations to be evaluated

In accordance with CS 25.571(a), a damage tolerance and fatigue evaluation should be conducted for each part of the structure which could contribute to a catastrophic failure. PSEs such as wing, empennage, control surfaces and their systems, the fuselage, engine mountings, landing gears, and their related primary attachments, and all DDPs susceptible to fatigue that could contribute to a catastrophic failure should be evaluated.

In accordance with CS 25.571(a)(1)(ii), this evaluation must include the identification of PSEs and DDPs, the failure of which could contribute to catastrophic failure of the aeroplane. As defined in this AMC, a principal structural element is an element of structure that contributes significantly to the carrying of flight, ground, or pressurisation loads and whose integrity is essential in maintaining the overall structural integrity of the aeroplane. When identifying PSEs, consideration should be given to the effect caused by partial or complete loss or failure of structure with respect to continued safe flight and landing, considering all flight phases including stability, control and aeroelasticity.

A DDP is an area at higher risk of fatigue cracking than other areas, and may warrant specific actions such as special inspections or other procedures to ensure continued airworthiness.

(1) Locations requiring evaluation can be determined by analysis or by fatigue tests on complete structures or subcomponents. However, tests may be necessary when the basis for analytical prediction is not reliable, such as for complex components. If less than the complete structure is tested, care should be taken to ensure that the internal loads and boundary conditions are valid.

The selection criteria for DDPs should also include the following considerations:

(a) any evidence of cracking encountered in service on a comparable structure;

(b) any evidence of cracking found during fatigue testing on a comparable structure;

(c) available strain gauge data;

(d) locations where permanent deformation occurred on static test articles;

(e) areas analytically shown to have a relatively low crack initiation life;

(f) susceptibility to corrosion or other environmental deterioration (e.g. disbonding);

(g) potential for manufacturing anomalies (e.g. new or novel manufacturing processes where the potential for damage may not be well understood);

(h) vulnerability to in-service induced accidental damage;

(i) areas whose failure would create high stresses in the remaining structure;

(j) elements in high tension or shear;

(k) low static margin;

(l) high stress concentrations;

(m) high load transfer;

(n) materials with high crack growth rates;

(o) some DDPs may exist outside of PSEs and may also have been classified as fatigue critical structure, e.g. undercarriage door attachments (see Appendix 5 for discussion on PSEs, FCS and DDP);

(p) areas where detection of damage would be difficult;

(q) locations subject to vibrations or other mechanisms that may lead to premature wear fastener holes; and

(r) locations vulnerable to moisture ingress or retention.

(2) Examples of principal structural elements (PSEs)

Typical examples of structure which are usually considered to be PSEs are:

(i) Wing and empennage

(a) control surfaces, slats, flaps, and their mechanical systems and attachments (hinges, tracks, and fittings);

(b) primary fittings;

(c) principal splices;

(d) skin or reinforcement around cut-outs or discontinuities;

(e) skin-stringer combinations or integrally stiffened plates;

(f) spar caps;

(g) spar webs; and

(h) ribs and bulkheads.

(ii) Fuselage

(a) circumferential frames and adjacent skin;

(b) pilot window posts;

(c) pressure bulkheads;

(d) skin and any single frame or stiffener element around a cut-out;

(e) skin or skin splices, or both, under circumferential loads;

(f) skin or skin splices, or both, under fore and aft loads;

(g) skin and stiffener combinations under fore and aft loads;

(h) door skins, frames, stops and latches;

(i) window frames; and

(j) floor beams[3].

(iii) Landing gear and their attachments

(iv) Engine mounts and struts

(v) Thrust reverser components, whose failure could result in inadvertent deployment

(3) Extent of Damage.

Each particular design should be assessed to establish appropriate damage criteria in relation to inspectability and damage-extension characteristics. In any damage determination, including those involving multiple cracks, it is possible to establish the extent of damage in terms of detectability with the inspection techniques to be used, the associated initially detectable crack size, the residual strength capabilities of the structure, and the likely damage-extension rate considering the expected stress redistribution under the repeated loads expected in service and with the expected inspection frequency. Thus, an obvious partial failure could be considered to be the extent of the damage or residual strength assessment, provided a positive determination is made that the fatigue cracks will be detectable by the available inspection techniques at a sufficiently early stage of the crack development. The following are typical examples of partial failures which should be considered in the evaluation:

(i) Detectable skin cracks emanating from the edge of structural openings or cutouts;

(ii) A detectable circumferential or longitudinal skin crack in the basic fuselage structure;

(iii) Complete severance of interior frame elements or stiffeners in addition to a detectable crack in the adjacent skin;

(iv) A detectable failure of one element where dual construction is utilised in components such as spar caps, window posts, window or door frames, and skin structure;

(v) The presence of a detectable fatigue failure in at least the tension portion of the spar web or similar element; and

(vi) The detectable failure of a primary attachment, including a control surface hinge and fitting.

(g) Inaccessible areas

Every reasonable effort should be made to ensure inspectability (reference CS 25.611) of all structural parts. In those cases where inaccessible and uninspectable blind areas exist, the damage tolerance evaluation should allow for extension of damage into detectable areas or demonstrate sufficient residual strength up to the LOV without inspection.

(h) Residual strength testing of principal structural elements

Analytical prediction of the residual strength of structures can be very complex due to non-linear behaviour, load redistribution and the potential for a multiplicity of failure modes. The nature and extent of residual strength tests will depend on previous experience with similar structures. Simulated cracks should be as representative as possible of actual fatigue damage. Where it is not practical to produce actual fatigue cracks, damage can be simulated by cuts made with a fine saw, sharp blade, guillotine, or other suitable means. Whatever artificial means are used to simulate sharp fatigue cracks, sufficient evidence should be available from tests to indicate equivalent residual strength. If equivalency cannot be shown, every attempt should be made to apply enough cyclic loading to generate fatigue cracks from the artificial damage prior to applying residual strength loads. Special consideration should be given to the procedure for pre-cracking so that subsequent test results are representative. This can be an issue when slow stable tearing in ductile sheet or plate material is part of the failure mechanism. Inappropriate pre-cracking loads can lead to non-conservative results. In those cases where bolt failure, or its equivalent, is to be simulated as part of a possible damage configuration in joints or fittings, bolts can be removed to provide that part of the simulation.

(i) Damage tolerance analysis and tests

(1) It should be determined by analysis, supported by test evidence, that:

(i) the structure, with the extent of damage established for residual strength evaluation, can withstand the specified residual strength loads (considered as ultimate loads); and

(ii) the crack growth life under the repeated loads expected in service (between the time the damage becomes initially detectable and the time the extent of damage reaches the value for residual strength evaluation) provides a practical basis for development of the inspection programme and procedures described in Section 8 of this AMC.

(2) The repeated loads should be as defined in the loading, temperature, and humidity spectra. The loading conditions should take into account the effects of structural flexibility and rate of loading where they are significant.

(3) The damage tolerance characteristics can be shown analytically by reliable or conservative methods such as the following:

(i) By demonstrating quantitative relationships with structure already verified as damage-tolerant; or

(ii) By demonstrating that the repeated loads and residual strength load stresses do not exceed those of previously verified designs of similar configuration, materials, and inspectability.

8. INSPECTION REQUIREMENTS

(a) Damage detection

Detection and repair of damage before it becomes critical is the most important factor in ensuring that the damage tolerance characteristics of the structure are maintained. For this reason, CS 25.571 requires that the applicant establish inspections or other procedures, as necessary, to prevent catastrophic failure from accidental, environmental, or fatigue damage, and include those inspections and procedures in the ALS of the Instructions for Continued Airworthiness required by CS 25.1529 (see also Appendix H to Part-25).

Due to the complex interactions of the many parameters that affect the damage tolerance evaluation, such as operating practices, environmental effects, load sequence effects on crack growth, and variations in inspection methods, operational experience should be taken into account in establishing inspection thresholds, repeat intervals, and inspection procedures.

(b) Environmental and accidental damage inspection programmes

The inspections developed under CS 25.571(b) are primarily for the detection of cracks developing from fatigue, accidental damage, and corrosion. As required by CS 25.571(a)(5), a separate programme needs to be implemented for the early detection of environmental and accidental damage. This is intended to minimise the risk of:

(1) interaction between corrosion and fatigue cracking;

(2) accidental damage developing into fatigue cracks; or

(3) corrosion developing due to accidental damage.

In many cases this can be accomplished through the Maintenance Review Board (MRB) activity or equivalent process agreed by EASA, for a new large aeroplane model using MSG-3 procedures. These procedures also require that a CPCP be developed.

For ED and AD programmes developed under the auspices of the MRB, the minimum ALS content associated with AD and ED may generally be limited to:

— a reference to the documents that contain the MRB report (MRBR) derived maintenance tasks for AD and ED; and

— the need to incorporate and maintain an effective CPCP in the operators’ programme; and

— a statement requiring operators to control corrosion to Level 1 or better.

It is also important to explain to operators the link between the AD and ED inspection programmes and CS 25.571 and CS 25.1529 compliance.

Inspections that are designed to detect fatigue cracking resulting from AD or ED, where the originating damage cannot otherwise be demonstrated to be detected prior to the development of the fatigue cracks, must also be directly included in the ALS. For new structure where there is limited supporting data from service experience, the MRB will depend heavily on input from the analyses and test programmes conducted by the applicant during certification, and for this reason significant cooperation is required between those involved directly in certification and those participating in the MRBR development. Care should also be taken to ensure that the damage assumptions made remain conservative after entry into service. A check of the continued validity of the certification assumptions can be achieved through fleet leader programmes and robust reporting requirements. If there is any doubt about the likely performance of a completely new structure with respect to AD and ED, certain specific inspections in vulnerable areas may be better placed in the ALS.

The baseline CPCP may be established through the MRB Industry Steering Committee (ISC) using existing procedures for MRBR development or developed by the applicant and submitted directly to EASA. (Note: Provided the operator has an NAA-approved maintenance programme that controls corrosion to Level 1 or better, it does not need to follow exactly the baseline CPCP offered by the type certificate holder (TCH). However, all revisions to the TCH’s programme for ED and AD must be considered by the operator for incorporation in the operators MP under the Part-M requirements.)

Reporting requirements for these programmes should extend to overhaul procedures where the condition of the part should be assessed and reported if outside of approved limits, whether or not it is to remain on the component being overhauled.

Changes and supplemental type certificates (STC) must also be provided with inspection programmes that address ED and AD.

(c) Inspection threshold for fatigue cracking

The inspection threshold is the point in time at which the first planned structural inspection is performed following entry into service. The threshold may be as low as the repeat interval, or may allow for a longer period of operation, provided certain conditions are met.

The concept of delaying an inspection threshold beyond the repeat interval is based on the premise that it will take a certain amount of time before fatigue cracks would develop to a size that would be detectable during a structural inspection. Consequently, it may be acceptable to wait some period of time before starting to inspect for fatigue cracks.

CS 25.571(a)(4) requires inspection thresholds for certain structure to be derived assuming that the structure contains an initial flaw of the maximum probable size that could exist as a result of manufacturing processes or manufacturing or service-induced damage. For metallic structure this would typically be achieved using crack growth analysis supported by tests. This approach applies to:

(1) single load path structure, and

(2) multiple load path ‘fail-safe’ structure and crack arrest ‘fail-safe’ structure, where it cannot be demonstrated that the resulting load path failure or partial failure (including arrested cracks) will be detected and repaired during normal maintenance, inspection, or operation of an aeroplane prior to failure of the remaining structure.

In this context, normal maintenance includes general visual structural inspections for accidental and environmental damage derived from processes such as the MRB application of MSG-3. Inspections should begin early enough to ensure that there is a high confidence of detecting cracks before they could lead to a catastrophic structural failure.

For the locations addressed by CS 25.571(a)(4) that are also susceptible to accidental (manufacturing or service induced) damage, the assumed initial flaw size for crack growth determination of the threshold should not be less than that which can be supported by service experience or test evidence. For example, if the type of damage expected is well defined, e.g. it is limited to dents, then there may be data that supports a longer threshold than would be derived by the assumption of a crack that is similar in size to the dent. However, in this case, the worst case manufacturing flaw should still be considered as a crack and the most conservative resulting threshold adopted. If supporting data is not available (e.g. for a completely new design where no specific investigation of the accidental damage threats or their influence on fatigue has been made), then the fatigue cracking inspection threshold should be set equal to the repeat interval derived for a crack detectable by general visual inspection means, since the initial damage and its growth is not well defined and could occur at any time.

The remaining areas of the structure evaluated under CS 25.571(b), i.e. multiple load path ‘fail-safe’ structure and crack arrest ‘fail-safe’ structure, where it can be demonstrated that the resulting load path failure, partial failure, or crack arrest will be detected and repaired during normal maintenance, inspection, or operation of an aeroplane prior to failure of the remaining structure must also have thresholds established for fatigue cracking. For these locations, methods that do not account for worst-case damage may be used in lieu of crack growth analysis if desired. For example, fatigue SN analysis and tests with an appropriate scatter factor or slow crack growth analysis based on appropriate initial manufacturing damage, i.e. typical manufacturing flaws as opposed to the maximum probable flaw (e.g. a 0.127 mm corner crack representing a typical manufacturing flaw in a fastener hole versus a 1.27 mm crack representing the maximum probable flaw).

The means of establishing the LOV and maintenance actions (including inspections) specifically associated to WFD is addressed in detail in Section 11 of this AMC.

All inspections necessary to detect fatigue cracking that have thresholds less than the approved operating limitation (LOV or interim limitations) of the maintenance programme must be included in the ALS.

Appendix 3 provides further details on threshold determination.

(d) Inspection

The basis for setting inspection intervals is the period of time during which damage is detectable and the residual strength remains above the required levels. The reliability of the repeat inspection programme (i.e. frequency of inspections and probability of detection) should assure damage detection before the residual strength of the aircraft is compromised. Inspection intervals must be established by applying appropriate reduction factors to this period to ensure that the crack or other damage or failed load path will typically be found well before the residual strength of the structure drops below the required level. Long periods of exposure to residual strength levels only just above the load limit should be avoided. This applies in particular to crack-arrest structure. It should be borne in mind that CS 25.305 is the principle requirement for strength of the airframe, and that CS 25.571 is primarily intended to provide an inspection programme that will ensure the timely detection and repair of damage in order to restore the aircraft to the required (CS 25.305) strength capability and preserve this capability throughout the majority of the aircraft’s operational life.

Detectable crack sizes and shapes assumed to determine inspection intervals should be consistent with the inspection method capabilities and the cracking characteristics of the structure being evaluated. If concurrent cracking in adjacent areas or surrounding structure is expected within the operational life of the aeroplane, then this should be accounted for in the cracking scenario assumed.

9. FATIGUE (SAFE-LIFE) EVALUATION

9.1. Reserved

9.2. Fatigue (safe-life) evaluation

9.2.1. General

The evaluation of structure under the following fatigue (safe-life) strength evaluation methods is intended to ensure that catastrophic fatigue failure, as a result of the repeated loads of variable magnitude expected in service, will be avoided throughout the structure’s operational life. Under these methods the fatigue life of the structure should be determined. The evaluation should include the following:

(a) estimating or measuring the expected loading spectra of the structure;

(b) conducting a structural analysis, including consideration of the stress concentration effects;

(c) performing fatigue testing of structure which cannot be related to a test background to establish response to the typical loading spectrum expected in service;

(d) determining reliable replacement times by interpreting the loading history, variable load analyses, fatigue test data, service experience, and fatigue analysis;

(e) evaluating the possibility of fatigue initiation from sources such as corrosion, stress corrosion, disbonding, accidental damage, and manufacturing defects based on a review of the design, quality control, and past service experience; and

(f) providing necessary maintenance instructions including replacement times in the ICA in accordance with CS 25.1529.

9.2.2. Scatter factor for safe-life determination

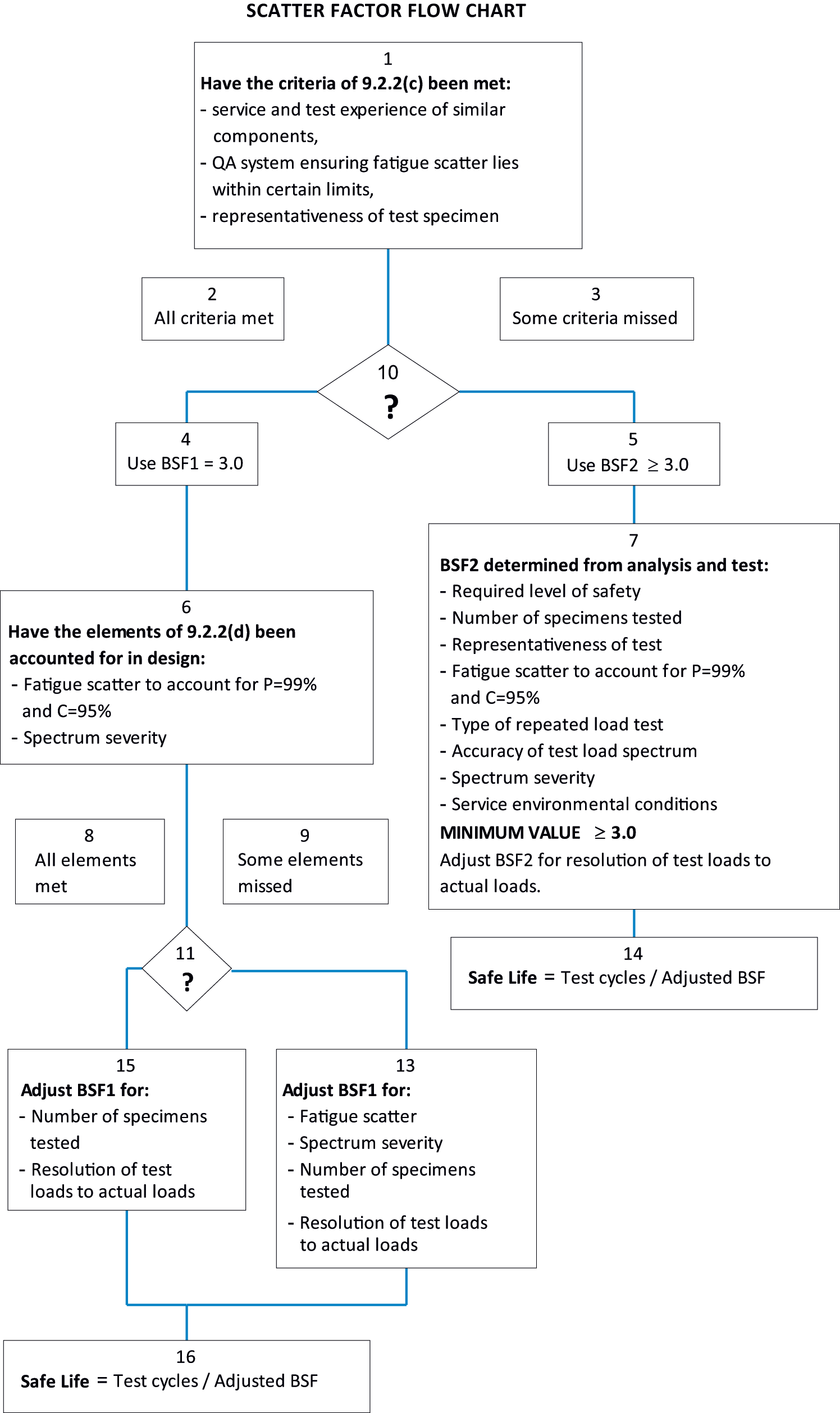

In the interpretation of fatigue analyses and test data the effect of variability should, under CS 25.571(c), be accounted for by an appropriate scatter factor. In this process it is appropriate that the applicant justifies the scatter factor chosen for any safe-life part. The following guidance is provided (see Figure 1):

(a) The base scatter factors (BSF) applicable to test results are: BSF1 = 3.0, and BSF2 = (see paragraph 9.2.2(e) of this AMC). If the applicant can meet the requirements of 9.2.2(c) of this AMC, he/she may use BSF1 or, at his/her option, BSF2.

(b) The base scatter factor, BSF1, is associated with test results of one representative test specimen.

(c) Justification for use of BSF1. BSF1 may only be used if the following criteria are met:

(i) Understanding of load paths and failure modes

Service and test experience of similar in-service components that were designed using similar design criteria and methods should demonstrate that the load paths and potential failure modes of the components are well understood.

(ii) Control of design, material, and manufacturing process quality

The applicant should demonstrate that his/her quality system (e.g. design, process control, and material standards) ensures the scatter in fatigue properties is controlled, and that the design of the fatigue-critical areas of the part account for the material scatter.

(iii) Representativeness of the test specimen

(A) The test article should be full scale (component or subcomponent) and represent that portion of the production aircraft requiring test. All differences between the test article and the production article should be accounted for either by analysis supported by test evidence, or by testing itself.

(B) Construction details, such as bracket attachments, clips, etc., should be accounted for, even though the items themselves may be non-loadbearing.

(C) Points of load application and reaction should accurately reflect those of the aircraft, ensure correct behaviour of the test article, and guard against uncharacteristic failures.

(D) Systems used to protect the structure against environmental degradation can have a negative effect on fatigue life, and therefore, should be included as part of the test article.

(d) Adjustments to base scatter factor BSF1. Having satisfied the criteria of paragraph 9.2.2(c), justifying the use of BSF1, the base value of 3.0 should be adjusted to account for the following considerations, as necessary, where not wholly taken into account by design analysis. As a result of the adjustments, the final scatter factor may be less than, equal to, or greater than 3.0.

(i) Material fatigue scatter. Material properties should be investigated up to a 99 % probability of survival and a 95 % level of confidence.

(ii) Spectrum severity. Test load spectrum should be derived based on a spectrum sensitive analysis accounting for variations in both utilisation (i.e. aircraft weight, cg, etc.) and occurrences/size of loads. The test load spectrum applied to the structure should be demonstrated to be conservative when compared to the expected usage in-service.

(iii) Number of representative test specimens. Well established statistical methods should be used that associate the number of items tested with the distribution chosen to obtain an adjustment to the base scatter factor.

(e) If the applicant cannot satisfy the intent of all of paragraph 9.2.2(c) of this AMC, BSF2 should be used.

(i) The applicant should propose scatter factor BSF2 based on careful consideration of the following issues: the required level of safety, the number of representative test specimens, how representative the test is, expected fatigue scatter, type of repeated load test, the accuracy of the test loads spectrum, spectrum severity, and the expected service environmental conditions.

(ii) In no case should the value of BSF2 be less than 3.0.

(f) Resolution of test loadings to actual loadings. The applicant may use a number of different approaches to reduce both the number of load cycles and the number of test set-ups required.

These include the following:

— spectrum blocking (i.e., a change in the spectrum load sequence to reduce the total number of test set-ups);

— high-load clipping (i.e., reduction of the highest spectrum loads to a level at which the beneficial effects of compression yield are reduced or eliminated); and

— low-load truncation (i.e., the removal of non-damaging load cycles to simplify the spectrum).

Due to the modifications to the flight-by-flight loading sequence, the applicant should propose either analytical or empirical approaches to quantify an adjustment to the number of test cycles which represents the difference between the test spectrum and the assumed flight-by-flight spectrum. In addition, an adjustment to the number of test cycles may be justified by raising or lowering the test load levels as long as appropriate data supports the applicant’s position. Other effects to be considered are different failure locations, different response to fretting conditions, temperature effects, etc. The analytical approach should use well-established methods or be supported by test evidence.

9.3. Replacement times

Replacement times should be established for parts with established safe-lives and should, under CS 25.571(a)(3), be included in the information prepared under CS 25.1529. These replacement times can be extended if additional data indicates an extension is warranted. Important factors which should be considered for such extensions include, but are not limited to, the following:

9.3.1. Comparison of original evaluation with service

experience

9.3.2. Recorded load and stress data

Recorded load and

stress data entails instrumenting aeroplanes in service to obtain a

representative sampling of actual loads and stresses experienced.

The data to be

measured includes airspeed, altitude and load factor versus time ; or

airspeed, altitude and strain ranges versus time ; or similar data. This data,

obtained by instrumenting aeroplanes in service, provides a basis for

correlating the estimated loading spectrum with the actual service experience.

9.3.3. Additional analyses and tests

If additional test

data and analyses based on repeated load tests of additional or surviving

specimens are obtained, a re-evaluation of the established safe-life can be

made.

9.3.4. Tests of parts removed from service

Repeated load tests

of replaced parts can be utilised to re-evaluate the established safe-life.

The tests should closely simulate service loading conditions.

Repeated load

testing of parts removed from service is especially useful where recorded load

data obtained in service are available since the actual loading experienced by

the part prior to replacement is known.

9.3.5. Repair or rework of the structure

In some cases,

repair or rework of the structure can gain further life.

9.4. Type design developments and changes

For design

developments, or design changes, involving structural configurations similar

to those of a design already shown to comply with the applicable provisions of

CS 25.571(c), it might be possible to evaluate the variations in critical

portions of the structure on a comparative basis. A typical example would be

redesign of the landing gear structure for increased loads. This evaluation

should involve analysis of the predicted stresses of the redesigned primary

structure and correlation of the analysis with the analytical and test results

used in showing compliance of the original design with CS 25.571(c).

10. DISCRETE

SOURCE DAMAGE

(a) General

The purpose of this section is to establish EASA guidelines for the consistent selection of load conditions for residual strength substantiation in showing compliance with CS 25.571(e) and CS 25.903(d). The intent of these guidelines is to define, with a satisfactory level of confidence, the load conditions that will not be exceeded on the flight during which the specified incident of CS 25.571(e) or CS 25.903(d) occurs. In defining these load conditions, consideration has been given to the expected damage to the aeroplane, the anticipated response of the pilot at the time of the incident, and the actions of the pilot to avoid severe load environments for the remainder of the flight consistent with his/her knowledge that the aeroplane may be in a damaged state. Under CS 25.631 continued safe flight and landing is required following the bird impact. Following the guidance of this paragraph for assessing structural damage to any part whose failure or partial failure may prevent continued safe flight and landing is an acceptable means of compliance to CS 25.631.

(b) The maximum extent of immediately obvious damage from discrete sources (CS 25.571(e)) should be determined and the remaining structure shown, with an acceptable level of confidence, to have static strength for the maximum load (considered as ultimate load) expected during completion of the flight. For uncontained rotor failure addressed under the CS 25.903(d) requirements and for applicants following AMC 20-128A, likely structural damage may be assumed to be equivalent to that obtained by using the rotor burst model and associated trajectories defined in AMC 20-128A, paragraph 9.0 ‘Engine and APU Failure Model’. This assessment should also include an evaluation of the controllability of the aircraft in the event of damage to the flight control system.

(c) The loads considered as ultimate should not be less than those developed from the following:

(1) At the time of the occurrence:

(i) the maximum normal operating differential pressure including the external aerodynamic pressures during 1.0 g level flight, multiplied by a 1.1 factor, combined with 1.0 g flight loads;

(ii) starting from 1.0 g level flight at speeds up to Vc, any manoeuvre or any other flight path deviation caused by the specified incident of CS 25.571(e), taking into account any likely damage to the flight controls and pilot normal corrective action.

(2) For the continuation of the flight, the maximum appropriate cabin differential pressure (including the external aerodynamic pressure), combined with:

(i) 70 % of the limit flight manoeuvre loads as specified in CS 25.571(b) and, separately;

(ii) at the maximum operational speed, taking into account any appropriate reconfiguration and flight limitations, the 1.0 g loads plus incremental loads arising from application of 40 % of the limit gust velocity and turbulence intensities as specified in CS 25.341 at Vc.

(d) At any time, the aeroplane must be shown, by analysis, to be free from flutter and other aeroelastic instabilities up to the boundary of the aeroelastic stability envelope described in CS 25.629(b)(2) with any change in structural stiffness resulting from the incident, consistent with CS 25.629(d)(8), CS 25.571(e), and CS 25.903(d).

11. ESTABLISHING THE LOV AND MAINTENANCE ACTIONS TO PREVENT WFD

(a) Structural maintenance programme

Theoretically, if an aircraft is properly maintained it could be operated indefinitely. However, it should be noted that structural maintenance tasks for an aircraft are not constant with time. Typically, tasks are added to the maintenance programme as the aircraft ages. It is reasonable to expect then that confidence in the effectiveness of the current structural maintenance tasks may not, at some future point, be sufficient for continued operation.

Maintenance tasks for a particular aircraft can only be determined based on what is known about that aircraft model at any given time: from analyses, tests, service experience, and teardown inspections. Widespread fatigue damage is of particular concern because inspection methods cannot be relied on solely to ensure the continued airworthiness of aircraft indefinitely. When inspections are focused on details in small areas and have a high probability of detection, they may be used by themselves to ensure continued airworthiness, unless or until there are in-service findings. Based on findings, these inspections may need to be modified, and it may be necessary to modify or replace the structure rather than continue with the inspection alone.

When inspections examine multiple details over large areas for relatively small cracks, they should not be used by themselves. Instead, they should be used to supplement the modification or replacement of the structure. This is because it would be difficult to achieve the probability of detection required to allow inspection to be used indefinitely as a means to ensure continued operational safety.

To prevent WFD from occurring, the structure must, therefore, occasionally be modified or replaced. Establishing all the replacements and modifications required to operate the aircraft indefinitely is an unbounded problem. This problem is solved by establishing an LOV of the engineering data that supports the structural maintenance programme. All necessary modifications and replacements are required to be established to ensure continued airworthiness up to the LOV. See paragraph 11(f) for the steps to extend the LOV.

(b) Widespread fatigue damage

Structural fatigue damage is progressive. It begins as minute cracks, and those cracks grow under the action of repeated stresses. It can be due to normal operational conditions and design attributes, or to isolated incidents such as material defects, poor fabrication quality, or corrosion pits, dings, or scratches. Fatigue damage can occur locally, in small areas or structural design details, or globally. Global fatigue damage is general degradation of large areas of structure with similar structural details and stress levels. Global damage may occur within a single structural element, such as a single rivet line of a lap splice joining two large skin panels (multiple site damage). Or it may be found in multiple elements, such as adjacent frames or stringers (multiple element damage). Multiple site damage and multiple element damage cracks are typically too small initially to be reliably detected with normal inspection methods. Without intervention these cracks will grow, and eventually compromise the structural integrity of the aircraft in a condition known as widespread fatigue damage. Widespread fatigue damage is increasingly likely as the aircraft ages, and is certain to occur if the aircraft is operated long enough without any intervention.

(c) Steps for establishing an LOV

The LOV is established as an upper limit to aeroplane operation with the inspections and other procedures provided under CS 25.1529 and Appendix H. The LOV is required by CS 25.571(a)(3) and is established because of increased uncertainties in fatigue and damage tolerance assessment and the probable development of widespread fatigue damage associated with aeroplane operation past the limit.

To support the establishment of the LOV, the applicant must demonstrate by test evidence and analysis at a minimum, and, if available, service experience and teardown inspection results of high-time aircraft, that WFD is unlikely to occur in that aircraft up to the LOV.

The process for establishing an LOV involves four steps:

— identifying a ‘candidate LOV’;

— identifying WFD-susceptible structure;

— performing a WFD evaluation of all susceptible structure; and

— finalising the LOV and establishing necessary maintenance actions.

Step 1 — Candidate LOV

Any LOV can be valid as long as it has been demonstrated that the aircraft model will be free from WFD up to the LOV based on the aircraft's inherent fatigue characteristics and that any required maintenance actions are in place. Early in the certification process applicants typically establish design service goals or their equivalent and set a design service objective to have structure remain relatively free from cracking, up to the design service goal. A recommended approach sets the ‘candidate LOV’ equal to the design service goal. The final LOV would depend on both how well that design objective was met, and the applicant’s consideration of the economic impact of maintenance actions required to preclude WFD up to the final LOV.

Step 2 — Identify WFD-susceptible structure

The applicant should identify the structure that is susceptible to WFD to support post-fatigue test teardown inspections or residual strength testing necessary to demonstrate that WFD will not occur in the aircraft structure up to the LOV. Appendix 2 to AMC 20-20 provides examples and illustrations of structure where multiple site damage or multiple element damage has been documented. The list in Appendix 2 to AMC 20-20 is not meant to be inclusive of all structure that might be susceptible to WFD on any given aircraft model and it should only be used for general guidance. It should not be used to exclude any particular structure.

The applicant should do the following when developing the list of structure susceptible to WFD:

(1) Establish criteria that could be used for identifying what structure is susceptible to WFD based on the definitions of multiple site damage, multiple element damage, and WFD. For example, structural details and elements that are repeated over large areas and operate at the same stress levels are obvious candidates. The criteria should be part of the applicant’s compliance data.

(2) Provide supporting rationale for including and excluding specific structural areas. This should be part of the applicant’s compliance data.

(3) Identify the structure to a level of detail required to support post-test activities that the applicant will use to evaluate the residual strength capabilities of the structure. Structure is free from WFD if the residual strength meets or exceeds that required by CS 25.571(b). Therefore, post-test activities such as teardown inspections and residual strength tests must provide data that support the determination of strength.

— For teardown inspections, specific structural details (e.g. holes, radii, fillets, cut-outs) need to be identified.

— For residual strength testing, the identification at the component or subcomponent level (e.g. longitudinal skin splices) may be sufficient.

Step 3 — Evaluation of WFD-susceptible

structure

Applicants must evaluate all susceptible structure identified in Step 2. Applicants must demonstrate, by full-scale fatigue test, evidence that WFD will not occur in the aircraft structure prior to the LOV. This demonstration typically entails full-scale fatigue testing, followed by teardown inspections and a quantitative evaluation of any finding or residual strength testing, or both. Additional guidance about full-scale fatigue test evidence is included in Appendix 2 to this AMC.

Step 4 — Finalise LOV

After all susceptible structure has been evaluated, finalise the LOV. The results of the evaluations performed in Step 3 will either demonstrate that the strength at the candidate LOV meets or exceeds the levels required by CS 25.571(b) or not. If it is demonstrated that the strength is equal to or greater than that required, the final LOV could be set to the candidate LOV without further evidence. If it is demonstrated that the strength is less than the required level, at least two outcomes are possible:

(1) The final LOV may be equal with the candidate LOV. However, this would result in maintenance actions, design changes, or both, maintenance actions and design changes, to support operation of aircraft up to LOV. For MSD/MED, the applicant may use damage tolerance-based inspections to supplement the replacement or modification required to preclude WFD when those inspections have been shown to be practical and reliable.

(2) The final LOV may be less than the candidate LOV. This could reduce the need for maintenance actions or making design changes.

Maintenance actions

In some cases maintenance actions may be necessary for an aircraft to reach its LOV. These maintenance actions could include inspections, modifications, replacements, or any combination thereof.

— For initial certification, these actions should be specified as airworthiness limitation items and incorporated into the ALS of the ICA.

— For post-certified aircraft, these actions should be specified as service information by the TCH or included in an updated ALS and may be mandated by Airworthiness Directives.

Design changes

The applicant may determine that developing design changes to prevent WFD in future production aircraft is to their advantage. The applicant must substantiate the design changes according to the guidance contained in this AMC

In addition to the technical considerations, the LOV may be influenced by several other factors, including:

— maintenance considerations;

— operator’s input; and

— economics.

(d) Airworthiness Limitations Section (ALS)

In accordance with Part-21 the TCH must provide the ICA (which includes the ALS) with the aircraft. However, the TCH may or may not have completed the full-scale fatigue test programme at the time of type certification.

Under CS 25.571, EASA may issue a type certificate for an aircraft model prior to the applicant’s completion of the full-scale fatigue testing, provided that EASA has agreed to the applicant’s plan for completing the required tests.

Until the full-scale fatigue testing is completed and EASA has approved the LOV, the applicant must establish a limitation that is equal to not more than one half of the number of cycles accumulated on the test article supporting the WFD evaluation. Under Appendix H to CS-25, the ALS must contain the limitation preventing operation of the aircraft beyond one half of the number of cycles accumulated on the fatigue test article approved under CS 25.571. This limitation is an airworthiness limitation. No aircraft may be operated beyond this limitation until fatigue testing is completed and an LOV is approved. As additional cycles on the fatigue test article are accumulated, this limitation may be adjusted accordingly. Upon completion of the full-scale fatigue test, applicants should perform specific inspections and analyses to determine whether WFD has occurred. Additional guidance on post-test WFD evaluations is included in Appendix 2 to this AMC.

At the time of type certification, the applicant should also show that at least one calendar year of safe operation has been substantiated by the fatigue test evidence agreed to be necessary to support other elements of the damage tolerance and safe-life substantiations. Some of these tests may require application of scatter factors greater than two resulting in more restrictive operating limitations on some parts of the structure.

After the full-scale fatigue test and the WFD evaluation have been completed, the applicant must include the following in the ALS:

— Under Appendix H to CS 25, the ALS must contain the LOV stated as a number of total accumulated flight cycles or flight hours approved under CS 25.571; and

— Depending on the results of the evaluation under Step 3 above, the ALS may also include requirements to inspect, modify or replace the structure.

(e) Repairs and type design changes

Any person applying for a change to a type certificate (TC) or a supplemental type certificate (STC) must demonstrate that any affected structure is free from WFD up to the LOV. (Note: It is possible that the STC applicant may generate a new LOV for the aeroplanes as part of the STC limitations).

Applicants for a major repair to the original aircraft or to an aircraft modified under a major change or an STC must demonstrate that any affected structure is free from WFD up to the LOV.

The evaluation should assess the susceptibility of the structure to WFD and, if it is susceptible, demonstrate that WFD will not occur prior to the LOV. If WFD is likely to occur before LOV is reached, the applicant must either:

(1) redesign the proposed repair to preclude WFD from occurring before the aircraft reaches the LOV; or

(2) develop maintenance actions to preclude WFD from occurring before the aircraft reaches the LOV; or

(3) for significant major changes and STCs only, establish a new LOV.

For repairs, the applicant must identify and include these actions as part of the repair. For major changes and STCs, the applicant must identify and include these actions as airworthiness limitation items in the ALS of the ICA. WFD evaluation is considered part of the fatigue and damage tolerance evaluation with respect to the three-stage repair approval process.

(f) Extended LOV

To extend an LOV, an application for a major change is required.

Typically, the data necessary to extend an LOV includes additional full-scale fatigue test evidence. The primary source of this test evidence should be full-scale fatigue testing. This testing should follow the guidance contained in Appendix 2 to this AMC.

[Amdt 25/19]

[3] Floor beams are not always critical but

should be checked for criticality, particularly those located next to cut-outs

or within non-circular pressurised sections.