Light

Dark

System

Log In

Loading...

Compare / EASA/

Incorporated Amendments

/

Compare & Highlight Differences

AMC No 2 to CS 29.865 External loads operations using simple personnel-carrying device systems

Available versions for ERULES-1963177438-14256

ED Decision 2018/015/R

found in: CS-29 Amdt 11 - Large Rotercraft (Feb 2023)

Select original version

...23)

...23)

Original Text

Select changed version

...23)

...23)

Changed text

Removed: 0

Added: 0

Unchanged: 0

Share

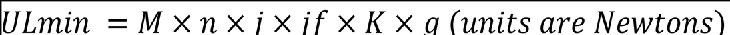

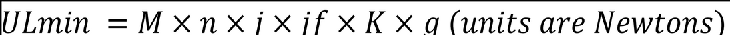

AMC No 2 to CS 29.865 External loads operations using simple personnel-carrying device systems ED Decision 2018/015/R If required by the applicable operating rule or if an applicant elects to, this AMC provides a means of compliance for the airworthiness certification of a simple personnel-carrying device system (PCDS) and attaching means to the hook, providing safety factors and consideration of calendar life replacement limits in lieu of a dedicated fatigue analysis and test. A PCDS is considered to be simple if: (a) it meets an EN standard under EC Directive 89/686/EEC, or Regulation (EU) 2016/425, as applicable, or subsequent revision; (b) it is designed to restrain no more than a single person (e.g. hoist or cargo hook operator, photographer, etc.) inside the cabin, or to restrain no more than two persons outside the cabin; (c) it is not a rigid structure such as a cage, a platform or a basket. PCDSs that cannot be considered to be simple are considered to be complex. Note 1: EASA or the relevant Authority should be contacted to confirm the classification in the event that: — a PCDS includes new or novel features; — a PCDS has not been proven by appreciable and satisfactory service experience; or — there is any doubt in the classification. Approval of Simple PCDSs If the approval of a simple PCDS is requested, then Directive 89/686/EEC, or Regulation (EU) 2016/425 are an acceptable basis for the certification of a simple PCDS provided that: (a) the applicable Directive 89/686/EEC or Regulation (EU) 2016/425, as applicable, or subsequent revision and corresponding EN standards for the respective components are complied with (EC Type Examination Certificate); (b) the applicant for the minor change has obtained from the manufacturer and keeps on record the applicable EC Conformity Certificate(s). Note 2: A simple PCDS has an EC Type Examination Certificate (similar to an STC), issued by a Notified Certification Body and, for the production and marketing, an EC Conformity Certificate (similar to an EASA Form 1) issued by the manufacturer. Note 3: In cases where ropes or elements connect simple PCDSs to the hoist/cargo hook or internal helicopter cabin, the EN certification can be achieved by a body meeting the transposition into national law of the applicable EC/EU regulation. The EC-certified components are appropriately qualified for the intended use and the environmental conditions. Note 4: The intended use and corresponding risks must be considered when selecting EN standards. For example hoist operators and rescuers that have to work at the edge of the cabin or outside should have full body harnesses to address the risk of inversion. Litters and the corresponding restraint systems should be adequately designed for the loads that can be generated during spinning. Note 5: The assembly of the different components should also consider the intended use. For example, the attachment of the tethering strap to the harness of a hoist operator should be of a DAD quick-release type to allow quick detachment from the aircraft following a ditching or emergency landing. The tethering strap should also be adjustable to take up slack and avoid shock loads being transmitted to other components. (c) The maximum load applied to each component between the HEC and the hook is conservatively estimated. This is particularly important when more than one person is attached by a single system to the cargo hook/ hoist. Appendix 1 defines the appropriate minimum ultimate load (ULmin). If ULmin is above the static strength currently declared by the supplier of the PCDS or of a component of the attachments, through compliance with an EN standard, then proof of sufficient strength is to be provided by static tests. All possible service load cases (including asymmetric load distribution) are to be considered. In this case, the PCDS and/or the attaching means (e.g. rope, carabineer, shackles, etc.) must be capable of supporting ULmin for a minimum of 3 minutes without failure. There should be no deformation of components that could allow the release of the HEC. Components and details added to the EN-approved equipment (such as splicing, knots, stitching, seams, press fits, etc.) or the materials used (textiles, composites, etc.) that might reduce the strength of a product or could (in combination) have other detrimental effects have been investigated by the applicant and accounted for in the substantiation. (d) The effects of ageing (due to sunlight, temperature, water immersion, etc.) and other operational factors that may affect the strength of the PCDS are accounted for through appropriate inspections and the application of a calendar life limit as appropriate. The PCDS and the related attachment elements are limited to the carriage of HEC. (e) The risk of fatigue failure is minimised. See section below for further details. (f) Instructions for Continued Airworthiness (ICA) should be provided. Typically, the ICA would comprise an inspection programme and maintenance instructions based on the applicable manufacturer’s data. The ICA should ensure that specific operational uses of the system that might affect its strength are accounted for. A calendar life limit should be applied when appropriate. (g) When the harness is not designed to transport an incapacitated or untrained person, then the labelling and/or the user/flight manual should include a specific limitation of use as applicable. Note 6: The following considerations and corresponding instructions/limitations should be taken for EN 1498 Type A and C rescue loops due to their potential detrimental physiological effects and the risk falling out: (a) whether life is in imminent risk; (b) the physical condition of the person to be hoisted, particularly whether the rescuee will remain conscious and coherent during the hoist process; (c) the potential for the person to remain compliant with the brief given prior to hoisting; (d) alternative methods and devices to recover the person; and (e) whether the risk of falling from the device would result in further serious injury or death. Simple PCDS Helicopter Compatibility The ingress/egress of the simple PCDS in the cabin should be verified on the specific rotorcraft by means of a test. The compatibility with the hoist hook, unless the ring is already specified in the RFM, should also be verified by means of a test. The verification of the hook and simple PCDS compatibility should also verify the absence of any roll-out/jamming phenomenon in order to: (a) prevent any inadvertent release of the load from the cargo hook; and/or (b) prevent the ring from jamming on the load beam during the release. Manufacturing and Identification Simple PCDSs that comply with Directive 89/686/EEC, or Regulation (EU) 2016/425, as applicable, or subsequent revision and the corresponding EN standards for the respective components are labelled by the manufacturer according to the applicable standard. If not already contained in the manufacturer labelling, the following additional information, as applicable, should be made visible on labelling on simple PCDSs: (a) manufacturing date; (b) life-limit date (if different from any existing one marked on the personal protective equipment (PPE)); (c) manufacturer’s identification; (d) part number; (e) serial number or unique identification of the single PCDS; (f) STC/minor change approval number (if applicable); (g) authorised load in kg; (h) authorised number of persons; (i) Any other limitation not recorded in the manufacturer labelling. Simple PCDS Static Strength The PCDS should be substantiated for the loading conditions determined under the applicable paragraphs of FAA AC 29.865. For a PCDS to be certified separately from the hoist, using the guidance of this certification memo, the minimum ultimate load (ULmin) to be substantiated is defined as follows:  Where: **M** is the total mass of the PCDS equipment/component and persons restrained by the part being substantiated (this is equivalent to the working load rating of an EN). The mass of each person should be assumed to be 100 kg. NOTE: If the person(s) or their task requires the personal carriage of heavy items (backpacks, tools, fire extinguishers, etc.), these must be accounted for in the total mass M, in addition to the person’s mass of 100 kg. n is the helicopter manoeuvring limit load factor and must be assumed = 3.5 ([CS 29.337](#_DxCrossRefBm1178331794) and [29.865](#_DxCrossRefBm1178331718)). j is the ultimate load factor of safety for all parts = 1.5 ([CS 29.303](#_DxCrossRefBm1178331783)). K is an additional safety factor for textiles = 2.0 (see NOTE 1) ([CS 29.619](#_DxCrossRefBm1178331867)). jf is an additional fitting factor = 1.33 applying to all joints, fittings, etc. ([CS 29.619](#_DxCrossRefBm1178331867)). g is the acceleration due to gravity of 9.81 m/s2. The resulting values to ensure compliance with the CS-29 static strength requirements are: ULmin for metallic elements with a fitting factor (needed for all joints and fittings): = 7 Mg. (NOTE: To address fatigue, a value of 10 Mg may be required; see the section below on fatigue.) ULmin for textiles (webbing, ropes, etc.) with fitting factor: = 14 Mg (see NOTE 1). ULmin may be compared to the strength of the PCDS components already substantiated according to Directive 89/686/EEC, or Regulation (EU) 2016/425, as applicable, or subsequent revision and the corresponding EN Standards or Directive 2006/42/EC Annex I Point 6. Where ULmin is greater than that laid down in the Directives/EN requirements, a static test to not less than ULmin will be necessary. The test load must be sustained for 3 minutes. In addition, there should be no detrimental or permanent deformation of the metallic components at 3.5 Mg ([CS 29.305](#_DxCrossRefBm1178331784)). NOTE 7: Directive 2006/42/EC Annex I Point 6 recommends a safety factor of 14 (2 × 7) for textiles applied to the working load (equivalent to 14 M above) for equipment lifting humans, whereas for a rescue harness, EN 1497 requires a static test load of not less than the greater of either 15 kN or 10 times the working load. Considering this difference, for each textile component within the PCDS certified to one of the following ENs, the value of K may be reduced, such that ULmin is not less than 10 Mg, where M is not more than 150 kg: For harnesses, EN 361, EN 1497 or EN 12277A, EN 813 or EN 12277C apply; for belts or straps and for lanyards, EN 354 applies. This allowance is not applicable to ropes. Furthermore, to allow this reduced value of ULmin and to address any potential deterioration of textiles due to environmental and other hidden damage, the ICA must include a life limitation of 5 years (or the life indicated by the PCDS manufacturer, if less) and an annual detailed inspection of the general condition of the harness. Simple PCDS Fatigue When the simple PCDS and the related attachment elements are limited to the carriage of HEC only, no further specific fatigue substantiation is necessary for each part of the simple PCDS that is either: (a) certified in accordance with an applicable EN that is referenced in this AMC for which the allowable working load is not exceeded by the mass M; or (b) substantiated for static strength as described above with ULmin not less than 10 Mg. [Amdt No: 29/5] [Amdt No: 29/6]

AMC No 2 to CS 29.865 External loads operations using simple personnel-carrying device systems ED Decision 2018/015/R8/015/R If required by the applicable operating rule or if an applicant elects to, this AMC provides a means of compliance for the airworthiness certification of a simple personnel-carrying device system (PCDS) and attaching means to the hook, providing safety factors and consideration of calendar life replacement limits in lieu of a dedicated fatigue analysis and test. A PCDS is considered to be simple if: (a) it meets an EN standard under EC Directive 89/686/EEC, or Regulation (EU) 2016/425, as applicable, or subsequent revision; (b) it is designed to restrain no more than a single person (e.g. hoist or cargo hook operator, photographer, etc.) inside the cabin, or to restrain no more than two persons outside the cabin; (c) it is not a rigid structure such as a cage, a platform or a basket. PCDSs that cannot be considered to be simple are considered to be complex. Note 1: EASA or the relevant Authority should be contacted to confirm the classification in the event that: — a PCDS includes new or novel features; — a PCDS has not been proven by appreciable and satisfactory service experience; or — there is any doubt in the classification. Approval of Simple PCDSs If the approval of a simple PCDS is requested, then Directive 89/686/EEC, or Regulation (EU) 2016/425 are an acceptable basis for the certification of a simple PCDS provided that: (a) the applicable Directive 89/686/EEC or Regulation (EU) 2016/425, as applicable, or subsequent revision and corresponding EN standards for the respective components are complied with (EC Type Examination Certificate); (b) the applicant for the minor change has obtained from the manufacturer and keeps on record the applicable EC Conformity Certificate(s). Note 2: A simple PCDS has an EC Type Examination Certificate (similar to an STC), issued by a Notified Certification Body and, for the production and marketing, an EC Conformity Certificate (similar to an EASA Form 1) issued by the manufacturer. Note 3: In cases where ropes or elements connect simple PCDSs to the hoist/cargo hook or internal helicopter cabin, the EN certification can be achieved by a body meeting the transposition into national law of the applicable EC/EU regulation. The EC-certified components are appropriately qualified for the intended use and the environmental conditions. Note 4: The intended use and corresponding risks must be considered when selecting EN standards. For example hoist operators and rescuers that have to work at the edge of the cabin or outside should have full body harnesses to address the risk of inversion. Litters and the corresponding restraint systems should be adequately designed for the loads that can be generated during spinning. Note 5: The assembly of the different components should also consider the intended use. For example, the attachment of the tethering strap to the harness of a hoist operator should be of a DAD quick-release type to allow quick detachment from the aircraft following a ditching or emergency landing. The tethering strap should also be adjustable to take up slack and avoid shock loads being transmitted to other components. (c) The maximum load applied to each component between the HEC and the hook is conservatively estimated. This is particularly important when more than one person is attached by a single system to the cargo hook/ hoist. Appendix 1 defines the appropriate minimum ultimate load (ULmin). If ULmin is above the static strength currently declared by the supplier of the PCDS or of a component of the attachments, through compliance with an EN standard, then proof of sufficient strength is to be provided by static tests. All possible service load cases (including asymmetric load distribution) are to be considered. In this case, the PCDS and/or the attaching means (e.g. rope, carabineer, shackles, etc.) must be capable of supporting ULmin for a minimum of 3 minutes without failure. There should be no deformation of components that could allow the release of the HEC. Components and details added to the EN-approved equipment (such as splicing, knots, stitching, seams, press fits, etc.) or the materials used (textiles, composites, etc.) that might reduce the strength of a product or could (in combination) have other detrimental effects have been investigated by the applicant and accounted for in the substantiation. (d) The effects of ageing (due to sunlight, temperature, water immersion, etc.) and other operational factors that may affect the strength of the PCDS are accounted for through appropriate inspections and the application of a calendar life limit as appropriate. The PCDS and the related attachment elements are limited to the carriage of HEC. (e) The risk of fatigue failure is minimised. See section below for further details. (f) Instructions for Continued Airworthiness (ICA) should be provided. Typically, the ICA would comprise an inspection programme and maintenance instructions based on the applicable manufacturer’s data. The ICA should ensure that specific operational uses of the system that might affect its strength are accounted for. A calendar life limit should be applied when appropriate. (g) When the harness is not designed to transport an incapacitated or untrained person, then the labelling and/or the user/flight manual should include a specific limitation of use as applicable. Note 6: The following considerations and corresponding instructions/limitations should be taken for EN 1498 Type A and C rescue loops due to their potential detrimental physiological effects and the risk falling out: (a) whether life is in imminent risk; (b) the physical condition of the person to be hoisted, particularly whether the rescuee will remain conscious and coherent during the hoist process; (c) the potential for the person to remain compliant with the brief given prior to hoisting; (d) alternative methods and devices to recover the person; and (e) whether the risk of falling from the device would result in further serious injury or death. Simple PCDS Helicopter Compatibility The ingress/egress of the simple PCDS in the cabin should be verified on the specific rotorcraft by means of a test. The compatibility with the hoist hook, unless the ring is already specified in the RFM, should also be verified by means of a test. The verification of the hook and simple PCDS compatibility should also verify the absence of any roll-out/jamming phenomenon in order to: (a) prevent any inadvertent release of the load from the cargo hook; and/or (b) prevent the ring from jamming on the load beam during the release. Manufacturing and Identification Simple PCDSs that comply with Directive 89/686/EEC, or Regulation (EU) 2016/425, as applicable, or subsequent revision and the corresponding EN standards for the respective components are labelled by the manufacturer according to the applicable standard. If not already contained in the manufacturer labelling, the following additional information, as applicable, should be made visible on labelling on simple PCDSs: (a) manufacturing date; (b) life-limit date (if different from any existing one marked on the personal protective equipment (PPE)); (c) manufacturer’s identification; (d) part number; (e) serial number or unique identification of the single PCDS; (f) STC/minor change approval number (if applicable); (g) authorised load in kg; (h) authorised number of persons; (i) Any other limitation not recorded in the manufacturer labelling. Simple PCDS Static Strength The PCDS should be substantiated for the loading conditions determined under the applicable paragraphs of FAA AC 29.865. For a PCDS to be certified separately from the hoist, using the guidance of this certification memo, the minimum ultimate load (ULmin) to be substantiated is defined as follows:  Where: **M** is the total mass of the PCDS equipment/component and persons restrained by the part being substantiated (this is equivalent to the working load rating of an EN). The mass of each person should be assumed to be 100 kg. NOTE: If the person(s) or their task requires the personal carriage of heavy items (backpacks, tools, fire extinguishers, etc.), these must be accounted for in the total mass M, in addition to the person’s mass of 100 kg. n is the helicopter manoeuvring limit load factor and must be assumed = 3.5 ([CS 29.337](#_DxCrossRefBm1513259406) and [29.865](#_DxCrossRefBm1513259337)). j is the ultimate load factor of safety for all parts = 1.5 ([CS 29.303](#_DxCrossRefBm1513259401)). K is an additional safety factor for textiles = 2.0 (see NOTE 1) ([CS 29.619](#_DxCrossRefBm1513259470)). jf is an additional fitting factor = 1.33 applying to all joints, fittings, etc. ([CS 29.619](#_DxCrossRefBm1513259470)). g is the acceleration due to gravity of 9.81 m/s2. The resulting values to ensure compliance with the CS-29 static strength requirements are: ULmin for metallic elements with a fitting factor (needed for all joints and fittings): = 7 Mg. (NOTE: To address fatigue, a value of 10 Mg may be required; see the section below on fatigue.) ULmin for textiles (webbing, ropes, etc.) with fitting factor: = 14 Mg (see NOTE 1). ULmin may be compared to the strength of the PCDS components already substantiated according to Directive 89/686/EEC, or Regulation (EU) 2016/425, as applicable, or subsequent revision and the corresponding EN Standards or Directive 2006/42/EC Annex I Point 6. Where ULmin is greater than that laid down in the Directives/EN requirements, a static test to not less than ULmin will be necessary. The test load must be sustained for 3 minutes. In addition, there should be no detrimental or permanent deformation of the metallic components at 3.5 Mg ([CS 29.305](#_DxCrossRefBm1513259402)). NOTE 7: Directive 2006/42/EC Annex I Point 6 recommends a safety factor of 14 (2 × 7) for textiles applied to the working load (equivalent to 14 M above) for equipment lifting humans, whereas for a rescue harness, EN 1497 requires a static test load of not less than the greater of either 15 kN or 10 times the working load. Considering this difference, for each textile component within the PCDS certified to one of the following ENs, the value of K may be reduced, such that ULmin is not less than 10 Mg, where M is not more than 150 kg: For harnesses, EN 361, EN 1497 or EN 12277A, EN 813 or EN 12277C apply; for belts or straps and for lanyards, EN 354 applies. This allowance is not applicable to ropes. Furthermore, to allow this reduced value of ULmin and to address any potential deterioration of textiles due to environmental and other hidden damage, the ICA must include a life limitation of 5 years (or the life indicated by the PCDS manufacturer, if less) and an annual detailed inspection of the general condition of the harness. Simple PCDS Fatigue When the simple PCDS and the related attachment elements are limited to the carriage of HEC only, no further specific fatigue substantiation is necessary for each part of the simple PCDS that is either: (a) certified in accordance with an applicable EN that is referenced in this AMC for which the allowable working load is not exceeded by the mass M; or (b) substantiated for static strength as described above with ULmin not less than 10 Mg. [Amdt No: 29/5] [Amdt No: 29/6]